CMAX Profile,Pipe, WPC Series Special Use Strong Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

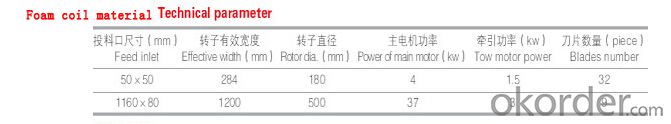

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

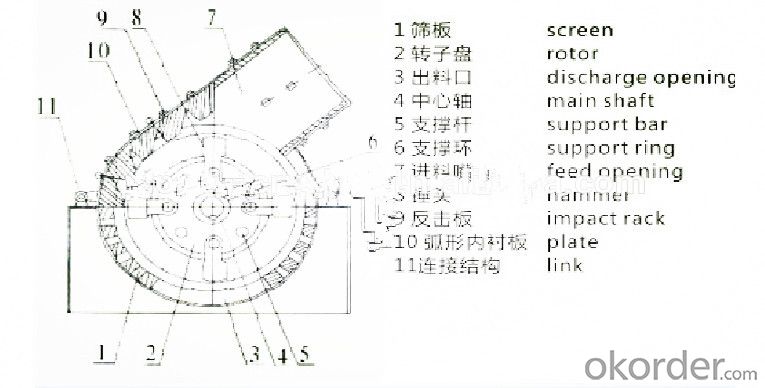

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

technical data

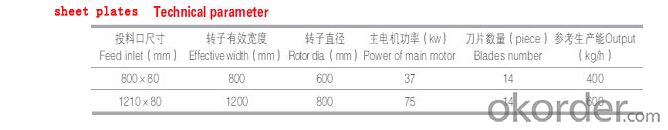

sheet plates technical

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q:Classification of equipment for plastics mills

- (two) powerful plastic crusher:1. The blade structure is between the claw knife and the flat knife. It is suitable for crushing the ordinary sheet, pipe, profile, plate and packing materials and other plastic products;2, universal plastic crusher, using sealed bearings, so that the rotation of the bearings for a long time to maintain good;3, design a reasonable knife, using steel blade, knife product granulating uniform, thermal processing, and through strict balance test, elegant appearance design;

- Q:How many kinds of crusher are there? What are the main differences? Please explain them in detail

- Crusher jaw crusher, impact crusher, hammer crusher, composite crusher, cone crusher, impact crusher, the main difference is the material processing fineness and yield of shape and principle are also different.

- Q:What are the differences between plastic crushers and particle machines, as well as the amount of money needed to buy machines and running capital? How much do I have to do to make it work? Yes, there are machines to buy machines, washing machines and crushers, and so on. Is everything a set? How much is the set? I'll do that. I'll go to the manufacturer and find the Department in it. And how do I ask him if he accepts my plastic?

- Compress and extrude and make plastic granules of mung bean size for easy use. Manufacturing of recycled plastic particles must have plastic crusher and plastic granulator, equipment according to advanced level and quality requirements, the price varies greatly,

- Q:What type of crusher is good for heavy crusher?

- The machine can replace the traditional jaw crusher and counterattack crusher two stage crushing, the user can save a lot of investment in equipment, and can produce grain shape excellent products.

- Q:PVC what's the best blade for plastic crushers?

- A better quality 6CrW2Si should be suitable for crushing and crushing most of the hard plastics, but the price is more expensive;

- Q:How to operate a plastic crusher correctly?

- Each brand is different, the use of plastic crusher will also be different

- Q:What does the crusher crush add to the weight of the crushing material?

- Crushing materials are generally sold to plastic factories, and HDPE materials are mainly used to make pots, barrels, turnover boxes, plastic pipes, hollow products, etc.. If you want to increase the added value of the broken material, it is better to break the material into pellets, which requires a plastic granulator (you can buy simple equipment, which is cheaper).

- Q:What kind of material is used for plastic hairpin?

- The hairpin is usually made of modified or nylon plastic.See if you're satisfied

- Q:How much does it cost to process a ton of plastic bottles?

- Market analysis of broken plastic bottles for waste plastics bottlesA bottle of mineral water and other waste polyester plastics have emerged, this kind of products except mineral water, and transparent bottles, beverage bottles of coke, because of its large volume, light weight, it is difficult to transport, so local processing is an economical and practical new way. Among them, it is the simplest and feasible way to break, clean and process plastic fragments. Besides removing the fixed waste materials, it can create economic benefits of about 300 yuan per ton, and the market prospect is very impressive.

- Q:Plastic crusher blade easily broken, because what?

- Third, heat treatment of hardness control, and proper tempering treatment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Profile,Pipe, WPC Series Special Use Strong Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products