CMAX High Output Fully Automatic Blow-molding Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

worked in this field for more than 5 years

Life span more than 15 years

world first class spare parts,lowest failure rate

Fully Automatic Blow-molding Machine

A:Brief Introduction

It can blow bottles in shapes for different use: medicine, food, pesticide, cosmetics, house-hold products, and other packing containers.

1).High Automatization:Automatic malfunction alarm systems, automatic protection from cold and periodic record of output.

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quality:Highly precise blow-mould closing system ensure quality.

4). Double proportional hydraulic system

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: LS(KOREA)

b).Pneumatic parts:YUKEN(JAPAN)

c).Controller of temperature:FUJI(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. Highly-efficient plasticizing mixing screw guarantees fully and evenly plasticization; elements of the mold head adopt good quality steel with precise finishing and heat treating.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.1 percent.

C16. Variable-frequency speed regulation, reduction gearbox, enjoying steady speed regulation, low noise and durability

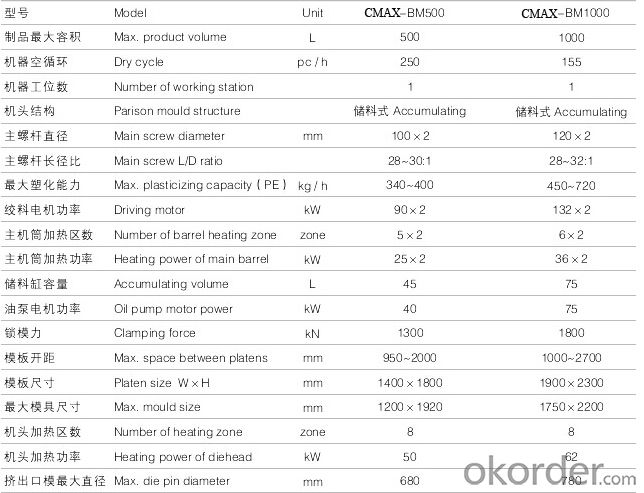

D.Technical Parameter:

A:Brief Introduction

It can blow bottles in shapes for different use: medicine, food, pesticide, cosmetics, house-hold products, and other packing containers.

1).High Automatization:Automatic malfunction alarm systems, automatic protection from cold and periodic record of output.

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quality:Highly precise blow-mould closing system ensure quality.

4). Double proportional hydraulic system

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

B.Settings:

a).PLC colour display: LS(KOREA)

b).Pneumatic parts:YUKEN(JAPAN)

c).Controller of temperature:FUJI(JAPAN)

d).Other electric parts are all world-famous brand

C.Machine Features:

C.1. Stable performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself.

C.4. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. Highly-efficient plasticizing mixing screw guarantees fully and evenly plasticization; elements of the mold head adopt good quality steel with precise finishing and heat treating.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.1 percent.

C16. Variable-frequency speed regulation, reduction gearbox, enjoying steady speed regulation, low noise and durability

D.Technical Parameter:

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q:What parameters should be provided for purchasing turbine oil filters?

- First, to see whether you need to filter the water and gas, if necessary, in general to choose the special vacuum oil turbine oil filter, such as the TYAXD series; if these particles can filter impurities, portable LY or LY plate oil filter can, by the way,

- Q:What's the problem of air compressor?

- In addition, if your air compressor is not mobile operations, you can use the following noise control methods:1, make separate airtight cover or, it is best to use stainless steel or other solid materials, glass to use hollow glass, two or more at the same time, around the office door closed to use the rubber pad of the door closed, it can be isolated from large scale2, in use sound-absorbing material of the ceiling, according to the specific situation of the selected units.3. The air compressor base is equipped with shockproof pad. If the vibration is reduced greatly, the service life of the equipment can be prolonged and the harm of noise will be reducedHowever, the harm of noise is invisible, and the accumulation of time can reflect the harm

- Q:Where is the vacuum oil purifier repaired?

- Vacuum oil filter is not a big problem, generally vacuum filter oil machine leakage, welding, welding die.

- Q:Vacuum oil filter price vacuum filter oil quotation vacuum filter oil machine how much?

- Vacuum oil prices of different brands, different manufacturers, different configurations, different models and different flow size, price is certainly not the same; the price of domestic and imported vacuum oil filter vacuum oil filter is certainly not the same.

- Q:Why is the oil filtered out of the oil filter cleaner?

- Improve the cleanliness of the oil, but filter it clean

- Q:How often does the oil filter in the turbine run oil filter change? Thank you for

- The oil pump pressure is also the object of surveillance. If you want to know how long it takes to change it, no one can say for sure.

- Q:The oil filtered by a vacuum oil filter is then placed in a centrifugal oil filter and filtered without salt water

- No, vacuum filtration only filters the sludge in the oil and does not filter out the phospholipids in the oil

- Q:What's the function of a centrifugal oil filter?

- Because the use of mixed liquid (cloudy) with light and heavy liquid and solid density and immiscible, in centrifugal force field or different settling velocity in the gravity field principle of the separation layer or the precipitation of solid particles in liquid purpose.

- Q:Why does the vacuum oil filter tank foam?

- 1: the fuel tank return port is improperly set, resulting in two gas mixing. Generally, the condensate gas tank, precipitation, slag falling settlement, oil return port is arranged below the surface of oil, the oil from the high drop into the tank, increase the chance of air into the oil, also caused a stir, let the water back by gravity sedimentation oil layer, bubble generation.2: steam turbine system design flaws or system aging and other man-made EH steam turbine oil system with steam or water, then will cause the oil emulsion, oil emulsion into the vacuum distillation tower, high temperature vacuum evaporation, bubble, if EH oil vacuum filter without defoaming or eliminating system bubble device damage will lead to the bubble with the oil into the tank to cycle.

- Q:Portable continuous refining machines and pneumatic oil filters that good

- First of all: you hit the wrong character, no portable oil refining machine, oil machine is also true of petrochemical enterprises will have less, while more than hundreds of thousands, millions, and refining facilities generally large, covers a wide area, how likely is portable, so you should be a portable oil filtering machine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX High Output Fully Automatic Blow-molding Plastic Extruder Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords