Clear Double Tempered Laminated Glass 3+0.38+3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Heat Absorbing Glass,Heat Reflective Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

colour: clear

edge: flat edge,grind edge,finepolished edge,bevelled edge

Packaging & Delivery of Double Tempered Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: 7-15 days

Specifications of Double Tempered Laminated Glass

1 Safety

2 Strength for resistance to impact

3 Strength for resistance to human body5 Sound insulation

1) safety

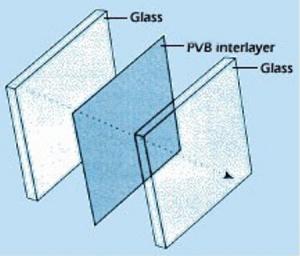

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living.

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

4)application

With unique characteristics ,the sandwich glass is widely adopted in artcles and occasions such as buildings grating,aloft grounds ,high-rank curtain walls windows and doors, furniture ,show windows, aquarium.

Specification of Double Tempered Laminated Glass

The color of PVB

(1) Euro grey

(2)light brozen

(3)dark blue

(4)green

(5)ocean blue

(6)F-green

(7)blue-green

(8)milky white

(9) light yellow

(10)chinese red

(11)purplish red

(12)orange

(13)clear

the type of glass

(1)clear float glass

(2)tinted glass

(3) reflective glass

Size

3300*2250mm,3300*2134mm,3210*2250,2440*1830mm,2440*1530 etc

Thickness

6.38mm,6.76mm,8.38mm,8.76mm,10.38mm,10.76mm,12.38mm,16.76mm etc

Laminated Glass Performance Levels according to Thickness

Glass Characteristic |

Thickness (mm) |

UV Transmittance (%) |

LT (%) |

3+0.38+3mm Clear |

6.38mm |

5 |

89 |

6+0.38+6mm Clear |

12.38mm |

3 |

86 |

6+0.38+6mm Reflective |

12.38mm |

0.5 |

22 |

- Q:Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- When the glass is heated to a suitable temperature, it cools rapidly, causing a sharp contraction of the glass surface and a compressive stress, while the cooling in the middle of the glass is slower and it is too late to shrink, thus forming a tensile stress and making the glass obtain a higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass.

- Q:How do you make the glass, please? What is the raw material?

- When you look for information, the proportion of raw materials is very important.

- Q:How is the glass made?

- Glass cup making process:1: silk;2: blow the ball;3: skin opening;4: inner opening and back cover;5: interface;6: back cover;7: affixed trademarks;8: annealing.Glass (glass) is the raw material is a glass of glass, usually raw material is high borosilicate glass, after more than 600 degrees of high temperature firing, it is a new type of environmentally friendly tea cup, more and more people's favor.

- Q:Is toughened glass dish loaded with food harmful to human body?

- Tempered glass is further processed on the basis of ordinary glass. Compared with ordinary glass, the impact resistance is greatly enhanced, and there is no sharp pointed fragment after fragmentation, and its heat resistance is greatly enhanced. However, it is not recommended that the toughened glass tableware be heated in a microwave oven, otherwise it may damage the product.

- Q:The difference between natural crystal and crystal glass, merits and demerits!

- Crystal glass, also known as lead crystal glass, this is a glass, but because of its luster, texture, sound and other characteristics are very similar to natural crystal, so called crystal glass.

- Q:What material is the automobile glass made of?

- The area of toughened glass is a new type of toughened glass, it through special treatment, can impact rupture, crack the glass can still maintain a certain clarity, ensure the driver's field of vision is not affected. At present, the front windshield of the car is mainly made of laminated tempered glass and sandwich area toughened glass, and it can bear strong impact force.

- Q:What are the cutting and cutting of acrylic and aluminum-plastic plates?

- The aluminum plastic composite plate is a composite material made of chemically treated coated aluminium plate as surface material, polyethylene plastic as core material, and manufactured on special aluminum plate production equipment. The unique properties of aluminum-plastic composite board itself has decided, its wide application: it can be used for building exterior wall, curtain wall, old building renovation, interior walls and ceiling decoration, advertising signs, display rack, dust purification engineering. The utility model belongs to a new type of building decoration material.

- Q:What is the raw material of glass?.

- 1. the main raw material of glass(1): the main component of silica sand or borax borax glass is introduced into silica or silica or boron oxide, which alone can melt into a glass body in the combustion, determines the main properties of glass, appropriately called silicate glass or borosilicate glass.(2): the main ingredients of soda soda or salt and mirabilite into glass is sodium, they can with silica sand and other acidic oxides formed in the fusible salt calcination, the fluxing action, the glass is easy to mold. But if the content is too much, the thermal expansion rate of glass will increase, and the tensile strength will decrease.(3) limestone, dolomite, feldspar, etc.: the main component of limestone introduced into glass is calcium oxide, which enhances the chemical stability and mechanical strength of glass. But the content is too much, which makes the glass break and reduce the heat resistance.As a raw material for introduction of Magnesium Oxide, dolomite can improve the transparency of glass, reduce thermal expansion and improve water resistance.Feldspar, as a raw material for introduction of alumina, can control the melting temperature and increase durability. In addition, potassium feldspar can also provide components, improve the thermal properties of glass.(4) broken glass: Generally speaking, not all new materials are used in the manufacture of glass, but the broken glass of 15%--30%.

- Q:The difference between crystal glass and glass

- Gloss: turn a high grade crystal glass against the light, and you will find it like a beautiful handicraft. White, glittering and translucent, and reflects the charming multicolored light, and low-end crystal or ordinary glassware in these areas there will be a big gap. What's more, in some ordinary glass containers, there are a lot of bubbles, and the color will be dirty and dark.Purchase of crystal glass

- Q:May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Clear Double Tempered Laminated Glass 3+0.38+3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords