Clay and High Alumina Refractory Mortars for Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Clay and High Alumina Refractory Mortars for Bricks is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of Clay and High Alumina Refractory Mortars for Bricks are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

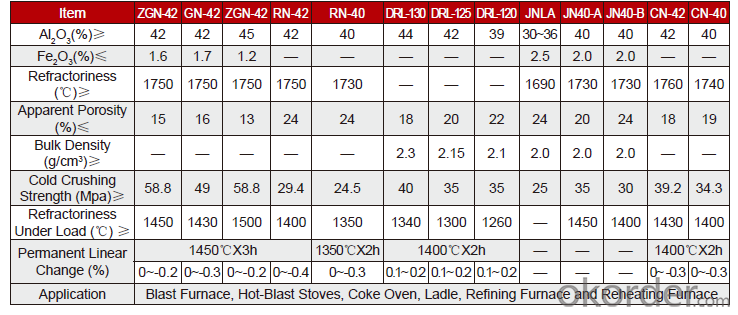

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What are needed to make refractory bricks with micro silica?

- Micro silicon powder is used in mortar and concrete, the ore-smelting electric furnace produces a large amount of strongly volatile gases SiO2 and Si, bridges, seaports. It is ferroalloy. When smelt ferrosilicon and industrial silicon (metallic cilicon), micro silicon power is also called silica fume or condensed silica fume, dam, gas emissions and air condensate and deposit by rapid oxidation, water conservancy, airport runway, tunnel, high-rise buildings, subway, railway, highway and culvert. Application fields of silicon power are cement concrete pavement and mine roadway anchor reinforcement and etc.

- Q:What is the best color of refractory brick

- Clay refractory brick: Yellow and deep yellow; acid-proof brick: Red, high alumina brick Beige, a little white; square viewing brick: Yellow, red, white, gray, brown, brown, nigger-brown and so on; color is just one aspect of the selection of refractory bricks, it mainly is to see the inherent quality

- Q:several refractory brick of rotary kiln several is damaged, how many refractory bricks should be replaced?

- The life of refractory bricks in rotary kiln is generally short.

- Q:Is the quality of refractory brick influenced if it is soaked by water

- Refractory bricks shouldn't be got wet by damp. Other refractory brick is not much problem, after touching, please wash hand, or masonry stove ignition will burst. In addition, refractory bricks containing chromium can't meet water, it's easy to hydrate and scrap, it will generate Cr VI ( chromium VI ), which is hanrmful to health and pollutes the environment, but try not to get wet

- Q:MU10 what are the non clay solid bricks?

- Clay solid brick with clay and is needed by adding admixture as raw materials, solid bricks by water mixing, molding, high temperature calcination made, mainly used for masonry bearing and non bearing wall, wall materials is a kind of widely used.

- Q:The making process of clay brick

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks. In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q:How many degrees of refractory brick if its surface turns red, how to test the temperature of refractory brick after it is burnt to red.

- If the raw materials are different, then the redness is different under different temperatures.

- Q:Whether the cement kiln refractory bricks belong to hazardous waste or not?

- No, there is no harmful gas produced, and it will not pollute the ground.

- Q:When the coal-fired steam boiler is built, it is necessary to build a common red brick between the refractory bricks. May I ask what is the requirement for this common red brick?

- unnecessary

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Clay and High Alumina Refractory Mortars for Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords