Ceramic Fiber Module with Low Conductivities

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Ceramic Fiber Module with Low Conductivities

Ceramic Fiber Module with Low Conductivities is made from long special ceramic fiber, formed by special strong double surface needling, without any binder ,increasing inter-weaving and tensile strength, so that ceramic fiber blanket own good stability under any working temperature.

Types of Ceramic Fiber Module with Low Conductivities: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Module with Low Conductivities also has difference, and they are suitable for different working temperatures.

Main Characteristics of the Ceramic Fiber Module with Low Conductivities

◆Good springiness for fiber

◆Excellent strength and resistance to blowing

◆Excellent chemical stability

◆Low thermal conductivity

◆Low thermal shrinkage

◆Excellent sound absorption

Application of Ceramic Fiber Module with Low Conductivities

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

◆Filling insulation and joint sealing

◆Back-up lining for industrial furnaces

◆Fireproof materials for construction

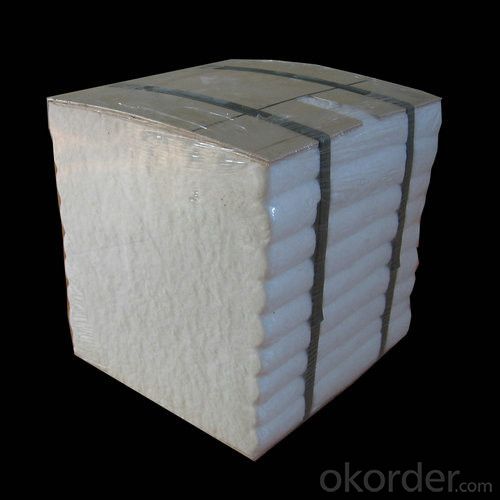

Ceramic Fiber Module with Low Conductivities Images

Ceramic Fiber Module with Low Conductivities Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | ≤3 | ≤3 | ≤3.5 | ≤3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Module with Low Conductivities

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you accept OEM for Ceramic Fiber Insulation Roll?

A:YES! We can according your demand to produce.

Q8:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

- Q:I heard sleeping without a pillow is better for your health and it made me think is it beneficial to sleep without blanketsI would still sleep on my bed sheets.

- 3M, oh wait that one is takenYeah, Flathead Valley Mobile Marine would be greatDo some quick checks to make sure nobody else has beaten you to the nameBest of luck in your new venture.

- Q:If i am able to do that what size do you think would be the best the thick kind or the thin kind? I would also like to add beads to it anyway possible that i could do that?

- I dont think its a good idea to pursue your mom, most of them do neat stuff like that:D

- Q:i'm new to autocad 2008 and doing my first drawings for classcan someone give me step-by-step instructions for how to draw batt insulation in my wall section? i googled it and all i can find are files and programs i can't understand as i have only learned basic cad functions thus farit has to go in 6quot; walls and look all.curvythank you!!

- u could A: try falling backk to sleep or i youaren'tt tired any more you could play games on a cell phone ipod etcif you dont have either of those you play games in your head or draw on a notepadI have the same problem at sleepovers those are some things i doI really hope i helped :)

- Q:My baby is going to be born in Dec I want to know how much and what I should have regarding baby clothes and blankets

- helloi'm interior an identical concernOur hormones get the final people, they do for awhileif your friends are being snobs all of the unexpected possibly they simply have something up their yet or comprehend you're a good guy or woman and experience like they do no longer deserve you or are in simple terms being stupid reason they're jealousI have not have been given any friends as properly one and of direction I fell in love with him and he's extremely like your friends and guyHow i'm getting by way of it, I say although, provide myself pep talks say in the event that they do unlike me then nice (confident it nevertheless gets to me very undesirable yet time beyond regulation I could pull myself out of it) do something via your self which you like, make a sparkling hobbie attempt issues outteach them you will possibly be autonomous and don't enable them to establish how undesirable that's bothering you people tend to maintain doing an identical concern until you destroyreducing is the greater serious concern you're able to do, i myself do it yet its an habit, you have come so use to hurting your self and whilst certainty soreness starts off you start up up hurting your self greateri % to propose you are not getting to down, shop your head upthis is a poor hollow to flow slowly out of its taken me years and that i'm nevertheless in itAnd for the guy if he won't have the capacity to establish how reliable you're then permit him bypass hell comprehend it quickly sufficientEver hear the asserting kill them with kindness? it works:) If issues worsen confer with a specified family contributors member or attempt and get counseling or shop a diarydesire I helped.

- Q:which car is better Maruti dzire topend diesel or i20 diesel?considering a diesel vehicle either Maruti sift dezire ZDI or top end i20 dieselwhich one should be better in terms of over all quality, comfort, space, maintainability, re-sale value after 3 years.

- The top floor insulation is either at the roof or the first floor ceiling, (floor of the attic), not bothIf it's already at the ceiling, the attic is vented to the outside, and insulating the roof would make very little differenceLaying an additional 'blanket on the floor is the way to go if you want to upgradeInsulating a roof increases the summer temperature of the roofing, and might adversely effect the life of some materials.

- Q:i cant move my bowels without a laxative, and if i dont take them i get really bloated and am in painthe laxatives are really tearing up my stomachgot any advice?

- One thing you need is toilet paper ,bread ,milk and Ramon noodles.

- Q:Anyone know if the Bed Head Ego Trip 3/4 Ceramic Straightener is a good straighter ?

- any flat iron is good as long as you know how to use it correctlyalways use a thermal protectant on your hair before putting any heat to itand flat iron in sectionscomb through first then spray tp then flat iron.

- Q:I am going to Chicago for my brothers boot camp graduationProblem is I need a jacket that will keep me warm the bestAny suggestions? Like what is the best insulation material?

- Get something that has a waterproof outer layer, and that the jacket itself comes in layers so you can adjust to the ever changing weatherMake sure it has a detachable hood, and if you have the money duck down would be good, as it is very warm but light.

- Q:I asked somewhat about this beforeBut I need to understand a few thingsFirst of all, is bat panel installation put up in 4x8 sheets on the studs like drywall, or is it cut and place between the 15 is 2x4 studs? Also, I was thinking of gettin paper-backed rolled insulation so I could just run it from top of wall to floor and staple to studs on each sideany better ideas? Which is cheaperthanks

- I like 4X8 styrofoam sheets 1/4, 1/2 or 3/4 thickness depending on your locationIt goes up easier than drywall and gives the same finished look if you use caulking on the seams and paint itThe best thing is it's cheap when weighed against the roll type and drywallTake a good sharp kitchen knife with you to cut it in half to fit your vehicle if you don't have access to a full size truck.

- Q:I need help.Fashion project due tomorrow and I have to write a 500 word essay on Nylon.please.

- good luck! Once you've been veg for a year I don't think there will be any going backI've been vegetarian for 9 months :)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Module with Low Conductivities

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products