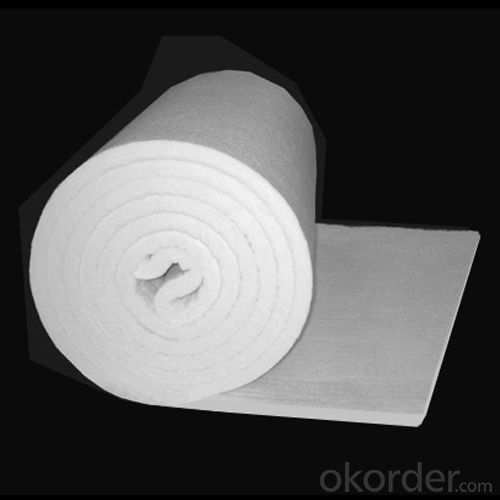

Ceramic FIber Blanket Refractory Blanket 1350C HP

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information:

Cmax ceramic fiber blanket is made from high quality gao-ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. No chemical binder is added. Double-size needling provides blanket with great tensile or handling strength for easy installation. Blankets are available in various classified temperature from 1260ºC to 1430ºC.

Cmax ceramic fibre blanket is resistant to most chemicals attack except hydrofluoric phosphoric acid and high pH alkali(na2o or k2o). Its thermal and physical properties can not be affected by oil, steam and water, very good thermal insulating materials.

Advantages:

Flexible

Resilient to thermal stock

High tensile strength

Corrosion resistance

Easy to install

Asbestos free

Application:

Petrochemical process heater refractory fiber lining

Heat treating furnace or intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

High temperature acoustic

Fire protection

Non-standard sizes are available upon request.

This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

| TECHNIQUE DATA | |||||||

| STD | HP | HA | HZ | ||||

| CLASSIFICATION TEMPERATURE(C) | 1260 | 1260 | 1350 | 1450 | |||

| WORKING TEMPERATURE(C) | 1000 | 1050 | 1200 | 1350 | |||

| COLOR | WHITE | WHITE | WHITE | WHITE | |||

| BULK DENSITY(kg/m 3 ) | 96/128 | 96/128 | 96/128 | 96/129 | |||

| THERMAL SHRINKAGE 24HRS (Density 128kg/m 3 ) | ≤ 3 | ≤ 3 | ≤ 3.5 | ≤ 3.5 | |||

| THERMAL CONDUCTIVITY(W/m. k) (Density 128kg/m3 ) | |||||||

| 800C | 0.15 | 0.176 | 0.160 | 0.155 | |||

| 1000C | 0.170 | 0.220 | 0.180 | 0.230 | |||

| 1200C | - | - | 0.260 | 0.31 | |||

| CHEMICAL COMPOSITION(%) | |||||||

| Al2O3 | 45-46 | 45-46 | 53-55 | 38-54 | |||

| SiO2+Al2O3 | 98.5 | 99 | 99 | 82-90 | |||

| ZrO2 | - | - | - | 13-18 | |||

| Fe2O3 | ≤ 0.4 | ≤ 0.3 | ≤ 0.3 | ≤ 0.3 | |||

- Q:Can refractory bricks be used when it cracks for 1cm

- 3, If the crack is caused by burning or drying, then it can't be used. While if the carck is caused by refractory brick molding, it still can be used. 4, the crack is caused by refractory bricks raw materials.

- Q:Why can't build refractory brick behind the skew block?

- Refractory is heat expansion and cold contraction, when it is high temperature, it will squeeze toward the center and the vault will be deformation .

- Q:What is refractory brick? What is refractory clay? ?

- Refractory bricks and refractory soil are all refractory materials. Generally they can be seen in the coke oven. The refractory brick is generally yellow. A steel brick is a kind of refractory brick. Its heavier several times than ordinary brick .

- Q:what kind of refractory brick is suitable for 1300 degrees converter?

- magnesia-carbon brick, you can also use MgO-Al2O3 castable, it is good too.

- Q:Whether yellow dextrin is used in refractory bricks?

- The production of refractory bricks needs yellow dextrin as bonded materials.

- Q:What's the difference between fired clay bricks and sintered porous bricks?

- Fired clay brick is a common brick made of clay as the main raw material. It is divided into five strength grades MU30, MU25, MU20, MU15 and MU10 according to the compressive strength. Strength, resistance to weathering of radioactive material and qualified brick, according to the size deviation, appearance quality, efflorescence and lime burst divided into high-class product (A), Al (B), (C) three qualified product quality grade. Excellent products for drywall and wall decoration, wall can be used for mixing first-class products, qualified products. Medium frosted bricks should not be used for damp parts. The shape of the brick is right angled hexahedron, its nominal size is: 240MM long, 115MM wide and 53MM high. The product mark of brick is written according to the product name, category, intensity grade, quality grade and standard number.

- Q:1200 degrees inside the furnace, lay a layer of refractory brick, what is the temperature outside?

- except refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and so on.

- Q:Are sintered brick concrete bricks?

- Many kinds of brick, according to the raw materials used for clay brick, shale, coal gangue brick, fly ash brick, lime sand bricks and slag brick;According to the production process can be divided into sintered brick and non fired brick, in which non fired brick can be divided into compressed brick, steam brick and autoclaved brick;With or without holes, ordinary bricks, porous bricks and hollow bricks can be divided into ordinary bricks.

- Q:Can someone tell me the refractory brick in the boiler mixed with what material to build the wall, and what proportion?

- Go to the refractory factory to buy some refractory clay that has the same texture of refractory bricks, the general boiler use clay refractory mortar.

- Q:can Methanol burn refractory brick?

- The upper part of the radiation chamber of the methanol oven is made of ceramic fiber, and the lower part is generally used refractory brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic FIber Blanket Refractory Blanket 1350C HP

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords