Cast Ductile Iron Manhole Covers D400 C250 for Industries with Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

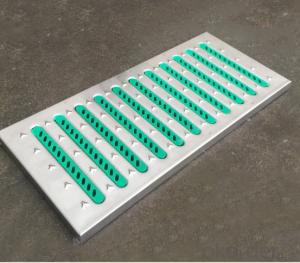

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| SC42 | C250 | 330*330 | 420*420 | 50 | 20 |

| RGC-01L | C250 | 390*325 | 530*465 | 100 | 23 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I get free samples?

A: Yes, we can provide the free samples, but you need to bear delivery freight.

3. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

- Q:ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger,

- Q:What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q:For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q:What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- Q:How can the casting be free of trachoma?

- 3, the gate is not facing sand core, flush sand core, will cause trachoma.

- Q:our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- The pre treatment temperature and the quality of plastic powder are likely to be problems

- Q:What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q:In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q:Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q:Heat treatment process and purpose of casting parts

- Objective: to stabilize tissues, eliminate or substantially reduce internal stress.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cast Ductile Iron Manhole Covers D400 C250 for Industries with Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords