HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

1. Product Performance for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

a).Hardness:50-65

b).Chromium percentage:0.25MAX

c).Heat treatment:cycles

d).Impact test>12AK.J/CM2

e).Endurance test times>=10000

f).Characteristic: a)unbreakable; b)even hardness; c)high impact value; d)good wear resistance; e) high combined efficiency of grinding mill

g).Productive technology: forging /hot-rolling

h).Packing:container bag:1000Kgs/Container Bag, Steel Drums: 850-900Kgs/Drum

i).Application : a) Mines b) Cement plants; c) Power stations; d) Chemical industry; e) other grinding industries.

j).Certificates: SGS/TUV/ ISO9001:2008

k). Microstructure: M+B+C(M-Martensite;B-Bainitic;C-Carbide)

2. Chemical Composition for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

Name | Material | C | Mn | Si | Cr | S | P |

CMAX-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-3 | 65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-4 | B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 |

CMAX-5 | 75SiMn | 0.70-0.90 | 0.70-1.20 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 |

CMAX-6 | Wear-resistant Alloy | 0.50-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 |

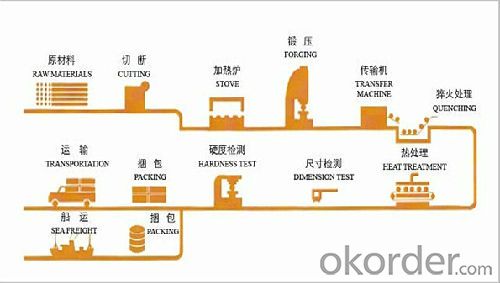

3. Production Process for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

3. Testing Methods for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

3. Packing Details for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Q:What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q:Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- The performance is too extensive, I think the following several people all fall into the erroneous zone directly, the performance includes a series of aspects:Mechanical properties: tensile strength, yield strength, elongation and contraction ratio of section and impact toughness after etc.

- Q:How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q:How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q:How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q:What are the casting parts processing engineering?

- At present, casting processing, according to metal classification, divided into cast iron, cast steel, casting non-ferrous metal.

- Q:In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q:What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 4, the performance requirements of the steel: whether castings or welding parts, there may be quality defects, but the casting will generally be worse than the weldment.You should be able to make a choice in the end.

- Q:The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

- Q:The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords