Carbon Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding End Caps

Features standards and products of our Butt-Welding End Caps:

Features of Butt-Welding End Caps:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding End Caps:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding End Caps:

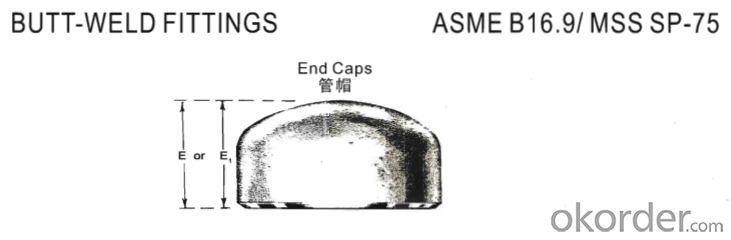

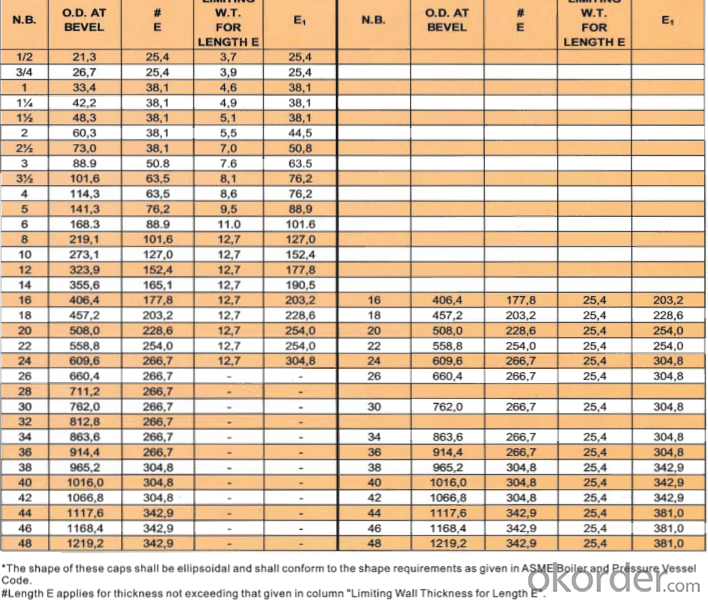

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding End Caps:

Packing of Butt-Welding End Caps:

FAQ of Butt-Welding End Caps:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:how do you use the Olds/Hurst Lightning Rod Shifters?

- Dude! He could have burned his retinas. The spark from an arc welder can be as bright as the sun. Take him to an emergency room, no matter how macho he tries to be. .

- Q:Do you have DN150-DN80 variable diameter steel pipe joint?

- GB-T12459-2005 seamless butt welded steel pipe, with all the data in it.

- Q:The pipe that is attached under the sink in the bathroom is corroded ,it is also attached to the wall.We cant put the other pipe back on bc their is no more threads to attach the drain.

- it depends of what type of fluid you are conveying, there are many codes like asme B31.1, i believe you can download if from the web, hope that helps, good luck.

- Q:Since they are faces and they go through the crowds during entrances will they give them a high five or a hand shake?

- I would go with disposable ones. I think if you get reusable ones they're much harder to clean. As for the coupler, you don't have to but if you decide to change the decorating tip on a certain bag of icing, you really cant because the coupler holds the decorating tip so if you want to change it, you just twist it off and apply a new one. I don't have couplers, but i guess its Okay. Just make sure you have the right bag of frosting with the right tip that way you don't make a mistake. Hope i helped :] Good Luck with your cake! :)

- Q:After downloading Artemis!138EF7B1E054 (trojan) my computer is in trouble!!! - I can't start programs by double clicking on them. I get a choose the program you want to open this file dialogue box. (This happens when using the Run command too.)- I can't access any programs in my Control Panel. I get Application Not Found error message. - I can't seem to fully install or uninstall any programs.Does this sound fixable? What can I do to fix it?Please keep in mind, I AM UNABLE TO INSTALL PROGRAMS. So any kind of Spyware remover is useless. Even online scans are useless because they need you to download something to run it. I would appreciate any help. Thanks.

- use sch 40 pipe or leave it alone

- Q:Is there a flawless way to access myspace from school? ive tried everything!?

- fittings permit a change in direction of piping, a change in diameter of pipe , or a branch to made from the main run of pipe. like elbow , reducer , tee couplings and nipples are used in socket welded and threaded systems and they joint pipe to pipe , or to nipple swage , joint tow different diameter pipe an d some like that.

- Q:I'm out there running the weedeater, with safety goggles and earplugs so I don't go deaf, and while doing the sidewalk, this young woman jogging and pushing her baby in a stroller runs RIGHT BY me (2 feet!).Dust, grass and a few pebbles are flying everywhere! Now, aside from the fact that she is an idiot, what are my (and her) legal rights? If she or her baby were injured, would that be my responsibility (New Jersey) ? I suppose, given the litigious nature of the US (and NJ), that I am probably responsible, but wondered if anyone knew for sure.Thanks

- I've often wondered that too. I'll go to the nearest fire hydrant and find out !! lol!!

- Q:My smoke detector is wired and dont use batteries. I dont know why it keeps sounding about every 10 to 15 min. it will beep once.

- I would always go with sweat if possible. I have used push (compression) fittings such as sharkbite only when there was water in the pipe that wouldn't go away or if a valve isn't holding.

- Q:does anyone know where I could locate this item .I have exhausted all my sources(stores)

- HAHAHAHAHAHAHAHAHA sorry i had to laugh :D ok yee call him :D

- Q:Would I still need to be concerned about carbon monoxide build up if I converted to a heat pump system for my home. I have no appliances that use gas. Could I then get rid of my carbon monoxide detector?

- I agree that the allowable pressure for a 3/4 piece of sch 40 pipe is about 2000 psi but that can vary depending on the type of manufacture. Some galvanized pipe is seamless and most is not seamless. That can make a difference as can the temperature at which the pipe is operating. The type and rating of any fittings are also a factor. You can get fitting with a nominal rating of as little as 150 psi to over 2000 psi.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Pipe Fittings Butt-Welding End Caps

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords