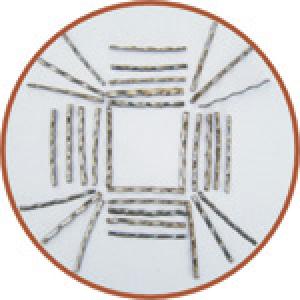

Carbon fiber shear

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mechanical Properties

| SFRC-0 | SFRC-1.0 | SFRC-1.5 | SFRC-2.0 |

Compressive strength Compressive strength(MPn) | 43.6 | 49.8 | 51.2 | 55.3 |

100% | 114.20% | 117.40% | 126.80% | |

Chop adn tension strength(MPn) | 3.74 | 4.89 | 5.7 | 6.58 |

100% | 129.90% | 152.40% | 175.90% | |

Bending strength with initial cracks(MPn) | 5.18 | 6.98 | 7.78 | 8.94 |

100% | 134.70% | 150.20% | 172.60% | |

Max.anti-deformation(MPa) | 5.6 | 9.4 | 10.7 | 13.9 |

100% | 167.80% | 191.10% | 248.20% | |

Toughness with initial cracks(Nmm) | 185.2 | 394.1 | 832.1 | 1161.1 |

100% | 212.80% | 449.30% | 627.00% |

Application in projects

Project Type | Length(mm) | Diameter(equilavent diameter mm) | Length/Diameter |

Ordinarily laid steel fiber concrete | 20-60 | 0.3-0.9 | 30-80 |

Steel fiber injected concrete | 20-35 | 0.3-0.8 | 30-80 |

Steel fiber concrete with earthquake resistant frame joints | 35-60 | 0.3-0.9 | 50-80 |

Steel fiber concrete railway sleeper | 30-35 | 0.3-0.6 | 50-70 |

Laminated steel fiber concrete complex road surface | 30-120 | 0.3-1.2 | 60-100 |

- Q:What are the different types of stainless steel wire screens for windows?

- For windows, there is a variety of stainless steel wire screens available, each with its own unique features and benefits. 1. Plain Weave Screens: These screens consist of stainless steel wires woven in a simple crisscross pattern. They are the most common and cost-effective option, offering basic protection against insects and debris. 2. Twill Weave Screens: Twill weave screens are similar to plain weave screens but have a more intricate pattern. This results in a tighter weave and increased strength, making them more resistant to damage. 3. Dutch Weave Screens: Dutch weave screens have a thicker warp wire and a thinner weft wire. This design creates a tight mesh with smaller openings, providing enhanced protection against smaller insects and pests. 4. Fine Mesh Screens: Fine mesh screens have a higher number of wires per inch, resulting in a tighter weave. These screens are specifically designed to keep out even the smallest insects, such as gnats and no-see-ums. 5. Stainless Steel Security Screens: Security screens are made from a heavier gauge stainless steel wire mesh, offering enhanced strength and security. These screens are highly durable and can withstand forced entry attempts, making them ideal for high-security applications. 6. Solar Screens: Solar screens are designed to block a significant amount of sunlight and UV rays while still allowing for airflow and visibility. They are often used in hot climates to reduce heat gain and improve energy efficiency. When choosing a stainless steel wire screen for your windows, it is essential to consider your specific needs and requirements. Factors such as insect protection, strength, durability, visibility, and energy efficiency should be taken into account to select the appropriate screen.

- Q:Can stainless steel wire be hardened?

- Stainless steel wire has the ability to undergo hardening. It belongs to a steel alloy category that contains at least 10.5% chromium, which contributes to its resistance against corrosion. While stainless steel wire is typically recognized for its robustness and endurance, it can also be hardened through a process known as cold working or strain hardening. This process involves subjecting the wire to mechanical deformation, such as bending or twisting, resulting in an increase in its strength and hardness. Nevertheless, it is essential to consider that stainless steel has a lower hardenability compared to other steel varieties, meaning that the level of hardness achieved through cold working may not be as high. If a higher level of hardness is desired, alternative heat treatment methods such as annealing and tempering can be utilized. However, it is important to note that these methods may impact the corrosion resistance properties of the stainless steel.

- Q:Can stainless steel wire be used for wire displays?

- Yes, stainless steel wire can be used for wire displays. Stainless steel wire is known for its durability, strength, and resistance to corrosion, making it an ideal material for wire displays. It can be used to create various types of displays such as shelving units, racks, baskets, and hangers. Stainless steel wire displays are commonly used in retail stores, supermarkets, exhibitions, and even in homes for organizing and showcasing products or items. The wire's sleek and modern appearance also adds a stylish touch to any display.

- Q:What are the environmental benefits of using stainless steel wire?

- There are several environmental benefits associated with using stainless steel wire. Firstly, stainless steel wire is a highly durable and long-lasting material. This means that products made with stainless steel wire have a longer lifespan compared to those made with other materials. As a result, the need for frequent replacements and disposal of products is reduced. This helps in reducing waste generation and the strain on landfills. Secondly, stainless steel wire is a corrosion-resistant material. This property allows it to withstand harsh environmental conditions without deteriorating. Consequently, products made with stainless steel wire require less maintenance and repair, reducing the need for additional resources and energy consumption. Additionally, stainless steel wire is recyclable. At the end of its lifespan, stainless steel wire can be easily reclaimed and recycled into new products without losing its properties. This reduces the demand for virgin raw materials and the energy required for their extraction and processing. By opting for stainless steel wire, we can contribute to the circular economy and promote sustainable resource management. Furthermore, stainless steel wire is resistant to heat and chemicals, making it ideal for various applications in industries such as construction, automotive, and marine. By using stainless steel wire in these sectors, we can minimize the use of other materials that may have a more significant environmental impact. Lastly, stainless steel wire is non-toxic and does not release harmful substances into the environment. This makes it a safe choice for applications where contact with food, water, or other sensitive environments is involved. In conclusion, using stainless steel wire offers several environmental benefits. Its durability, corrosion resistance, recyclability, and non-toxic nature contribute to reduced waste generation, lower energy consumption, and sustainable resource management. By opting for stainless steel wire, we can make a positive impact on the environment and promote a more sustainable future.

- Q:What are the different diameters available for stainless steel wire?

- There are several different diameters available for stainless steel wire, ranging from very thin to thicker options. The specific diameters can vary depending on the manufacturer and the intended use of the wire. Common diameter options for stainless steel wire include 0.02mm, 0.05mm, 0.1mm, 0.2mm, 0.5mm, 1mm, and larger. These diameters are typically measured in millimeters or sometimes in gauge sizes. It is important to choose the appropriate diameter based on the specific application requirements, such as strength, flexibility, or conductivity.

- Q:What is the tensile strength of stainless steel wire?

- The tensile strength of stainless steel wire can vary based on factors such as the specific grade or alloy used, as well as the manufacturing process and any heat treatment applied. Nevertheless, stainless steel wire generally possesses a high tensile strength. For instance, stainless steel wires like 304 and 316, which are commonly used, exhibit a tensile strength that ranges from approximately 550 MPa to 750 MPa (79,770 psi to 108,775 psi). This impressive tensile strength renders stainless steel wire suitable for a wide range of applications that necessitate both strength and resistance to corrosion. It is worth mentioning that the tensile strength can be further improved through specialized processing or alloy modifications in order to meet specific application requirements.

- Q:How can stainless steel and copper wire be welded?

- Stainless steel and copper wire welding can be brazed, and brazing, according to the temperature can be divided into cryogenic soft brazing and high temperature hard brazing.

- Q:Talking about the difference between mirror stainless steel and brushed stainless steel

- Brushed stainless steel is also a way of processing stainless steel, the surface has a trace of texture,.Mirror stainless steel words and brushed stainless steel characters are stainless steel, but the surface effect is not the same.

- Q:Is stainless steel wire suitable for wire rope connectors?

- Yes, stainless steel wire is suitable for wire rope connectors. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an excellent choice for wire rope connectors that require reliability and longevity in various applications.

- Q:Can stainless steel wire be supplied in custom tensile strengths?

- Yes, stainless steel wire can be supplied in custom tensile strengths. The tensile strength of stainless steel wire can be customized during the manufacturing process by adjusting the composition, heat treatment, and production methods. This allows for the production of stainless steel wire with varying levels of strength to meet specific requirements and applications. Whether you need high tensile strength or lower tensile strength stainless steel wire, it is possible to have it customized based on your needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon fiber shear

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords