Aluminum skirting board 6063-T5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

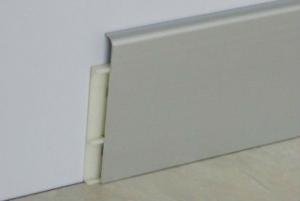

Aluminum skirting board 6063-T5

Main Characters

Functions: Visual balance; Decoration prettification; Protection for wall’s corners and floor.

Materials: Al 6063-T5

Hardness: 13~15 Degrees

Lifelong: 25 years over

Merits: Anti-fading; High Strength; Non-deformation; Water proof; Dump proof; Mothproof; Anti-friction; Aging resistance; Eco care; Recyclable; Easy to install;

- Q:how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q:What are the major factors determining the quality of aluminum profiles?

- With customers in the process of aluminum found billion purchase of aluminum profile, most do not know how to see the quality of aluminum profiles. And sometimes, many users in order to save costs, and select some cheaper industrial aluminum to do the work table stent, resulting in not long after the emergence of cracking, fading situation.

- Q:Are aluminum profiles suitable for lighting fixtures?

- Lighting fixtures can greatly benefit from the use of aluminum profiles. Aluminum, being a lightweight and versatile material, offers numerous advantages for lighting applications. To begin with, aluminum profiles possess excellent thermal conductivity. This means they effectively dissipate the heat generated by the lighting fixtures. Maintaining a cooler operating temperature is crucial as excessive heat can shorten the lifespan and impact the performance of the lighting components. By utilizing aluminum profiles, the longevity and efficiency of the lighting fixtures are enhanced. Moreover, aluminum profiles are resistant to corrosion, making them suitable for both indoor and outdoor lighting fixtures. This corrosion resistance ensures that the fixtures can endure harsh environmental conditions, such as high humidity or moisture exposure, without deteriorating or losing functionality. Additionally, aluminum profiles are easily customizable and can be tailored to meet various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility empowers manufacturers to create sleek and modern lighting solutions that seamlessly integrate into different architectural designs and spaces. Furthermore, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in a wide array of colors. This provides a plethora of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that can be fully recycled. By choosing aluminum profiles for lighting fixtures, one contributes to reducing environmental impact and supports the principles of sustainability. To summarize, aluminum profiles are highly suitable for lighting fixtures due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability. This is why they are extensively used in the lighting industry.

- Q:How to distinguish the true and false of aluminum profile

- When you make the Fenglv aluminum material before installation, be sure to carefully observe the surface of profile, the existence of marks. If you were not allowed to see on the surface, you have the right to request processing and installation personnel to do a good job in the windows and doors, open a door or window frame, see section profiles in the middle of the inner wall, do surface spray treatment, which can not be sprayed to the section, so you see the color profile is not covered by the powder, so it is easy to if there is differential profile marks. There is no any authentic Feng streak lines. We recommend you to see when the processing requirements of installation personnel open a door or window frame observation you specify, in the absence of color powder surface observation, differential can easily pull!The main difference between true and false identification is the difference between Feng materials, the relevant logo really materials have Feng Feng, and point code; there is a difference in structure, but the average person is not easy to identify, is false is imitation Feng al Feng material, so it is not 100% imitation, so the fixed window is different, the line is not the same, this point without a careful comparison is not too much attention; and actually is not the same aluminum surface treatment, surface color really Feng wavy uniform, did not occur, but not because it is relatively poor in the local aluminum equipment under the electrostatic spraying, it is not possible to achieve the level of surface treatment of aluminum.Now due to the requirements of the color type is more, so the regular manufacturers have no choice except white, green, there is no aluminum Nanjing stock, so the manufacturer had to really change color when Feng, this situation is best to distinguish between true and false identification to the Al Feng Nanjing office.

- Q:What is wearing a heat insulation aluminum profile? What is pouring heat insulation aluminum profile?

- Heat insulation aluminum section is to use glue strip to cut off the heat transfer of aluminum profile, popular point explanation, I'm not very professional.First, wear insulation:Extruded two aluminum sections, through the two bars to connect it to an aluminum profile, forming insulation profiles.Two 、 glue injection and heat insulation:An aluminum extrusion is extruded, and the aluminum material outside the rubber is cut off by pouring the heat insulation glue to form a heat insulation section.The price of the adhesive will be more expensive than the stripe.

- Q:What are the applications of aluminum profiles?

- Due to their unique characteristics and properties, aluminum profiles have a wide range of applications in various industries. Some of the main uses of aluminum profiles are as follows: 1. In the construction industry, aluminum profiles are extensively employed for windows, doors, curtain walls, and structural components. Their excellent strength, durability, and corrosion resistance make them ideal for building purposes. 2. The automotive industry utilizes aluminum profiles to manufacture lightweight and fuel-efficient vehicles. They are used in the production of car frames, engine mounts, heat exchangers, and other structural components. 3. The aerospace industry relies on aluminum profiles for their high strength-to-weight ratio. They are used in the construction of aircraft frames, wings, fuselage, and other critical components. 4. Aluminum profiles are widely used in electrical and electronics applications. Their excellent thermal conductivity and electrical insulation properties make them suitable for manufacturing heat sinks, LED lighting fixtures, electrical enclosures, and electronic device housings. 5. The furniture industry is increasingly incorporating aluminum profiles to create lightweight and stylish furniture pieces. They are used in the production of chairs, tables, cabinets, and shelving systems, providing a modern and aesthetic appeal. 6. Aluminum profiles play a significant role in the manufacturing of industrial machinery and equipment. They are utilized in the construction of conveyor systems, assembly line structures, machine frames, and guarding systems due to their lightweight, durability, and ease of fabrication. 7. In the marine industry, aluminum profiles are commonly used for their corrosion resistance and lightweight properties. They are utilized in the construction of boat frames, masts, hulls, and other marine structures. 8. Aluminum profiles also find applications in renewable energy systems such as solar panels and wind turbines. They are used in the manufacturing of solar panel frames, wind turbine supports, and mounting structures due to their lightweight nature and corrosion resistance. Overall, aluminum profiles offer a versatile and cost-effective solution for various industries, meeting their specific requirements for strength, durability, lightweight, and corrosion resistance.

- Q:Are there any differences between aluminum alloy and aluminum alloy?

- Aluminum alloy refers to the material, aluminum alloy refers to the productIt's like the difference between gold and gold

- Q:Can aluminum profiles be used for agricultural or farming applications?

- Yes, aluminum profiles can be used for agricultural or farming applications. Aluminum is lightweight, durable, and corrosion-resistant, making it suitable for various agricultural equipment and structures such as greenhouse frames, irrigation systems, storage sheds, and livestock enclosures. Additionally, aluminum profiles can be easily fabricated and customized to meet specific farming needs, making them a versatile choice for agricultural applications.

- Q:Can aluminum profiles be used for modular office partitions?

- Modular office partitions can indeed utilize aluminum profiles. These profiles possess characteristics such as lightness, durability, and a high strength-to-weight ratio, rendering them a perfect choice for constructing such partitions. They can be effortlessly transformed into different forms and sizes, thereby enabling customization and design flexibility. Moreover, aluminum profiles exhibit outstanding resistance against corrosion, guaranteeing prolonged performance even when exposed to high humidity conditions. Furthermore, they offer commendable thermal and sound insulation properties, thereby contributing to a pleasant and efficient office ambiance. In summary, owing to their versatility, durability, and aesthetic appeal, aluminum profiles remain a popular preference for modular office partitions.

- Q:Can aluminum profiles be used for industrial workbenches?

- Yes, aluminum profiles can be used for industrial workbenches. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications. Aluminum profiles can be easily customized, allowing for the construction of workbenches with specific dimensions and configurations. Additionally, aluminum profiles are often available in a wide range of sizes and shapes, providing flexibility in design. Overall, the use of aluminum profiles for industrial workbenches can offer strength, versatility, and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum skirting board 6063-T5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords