Aluminum Sheets AA1060 Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets AA1060 Used for Construction Description

Aluminum Sheets AA1060 Used for Construction is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets AA1060 Used for Construction is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA1060 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA1060 Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

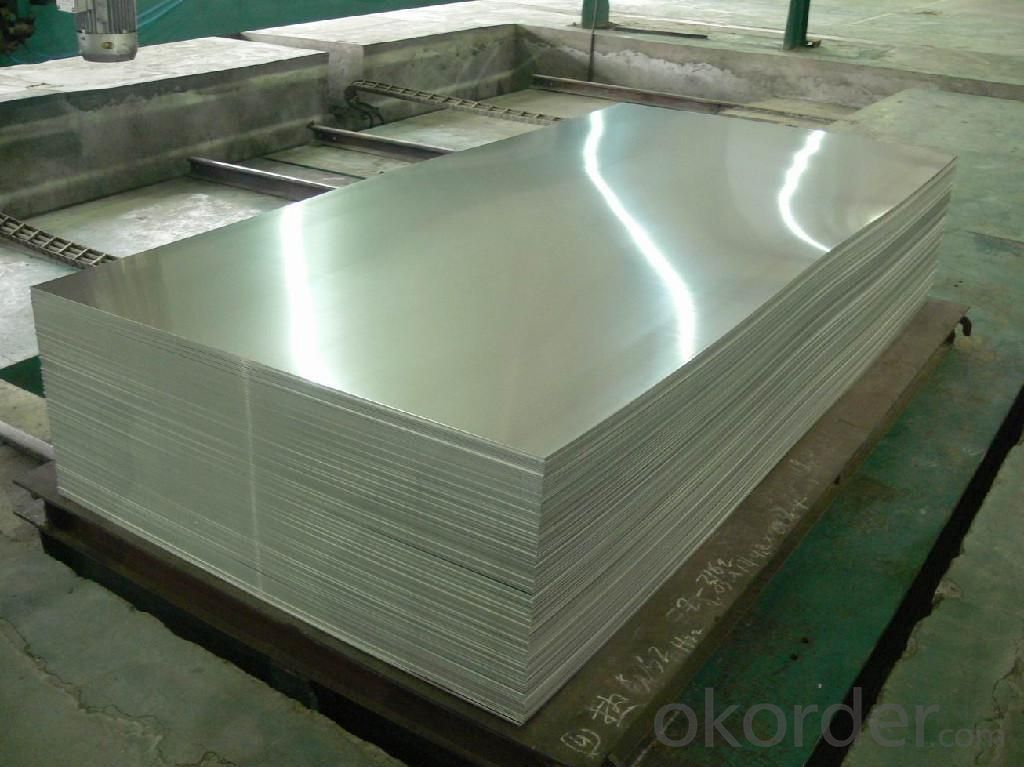

3.Aluminum Sheets AA1060 Used for Construction Images

4.Aluminum Sheets AA1060 Used for Construction Specification

Alloy | AA1060 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1060 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1060 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1060 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q:How do aluminum plates open holes?

- The opening of the aluminum plate is a relatively simple process,You can do that with a micro electric device like an electric drill or a grooving machine

- Q:What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q:or aluminum ? and what other gases are released?

- Aluminium does not normally react with water because of a surface coating of the highly unreactive Al2O3 that forms on exposure to atmospheric oxygen. In the presence of strong base, however, this compound dissolves due to complexation by hydroxide, similarly to how silver chloride dissolves in ammonia. Al2O3(s) + 2OH-(aq) + 3H2O(l) ----- 2[Al(OH)4]-(aq) Once this has occured, aluminium metal, a very strong reducing agent, is exposed to water. 2Al(s) + 6H+(aq) ----- 2Al3+(aq) + 3H2(g) Even though the solution is alkaline, there is still a low concentration of H+ formed by the autoprotolytic dissociation of water. The Al3+ formed then reacts with hydroxide to produce more [Al(OH)4]-. Yes, the hydrogen gas is from the water.

- Q:Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q:Can aluminum sheets be embossed?

- Indeed, it is possible to emboss aluminum sheets. The act of embossing entails producing a design that is elevated or inset on the surface of a material. Aluminum is a versatile substance that can be easily manipulated, including being subjected to embossing. One can employ different techniques in order to emboss aluminum sheets, such as heat embossing or using tools and machines specifically designed for embossing. By undergoing the embossing process, the aluminum sheets gain texture and depth, resulting in an enhanced appearance suitable for a wide range of applications. These applications may include decorative purposes, signage, nameplates, and even the addition of texture to automotive or architectural accents.

- Q:Are aluminum sheets suitable for use in harsh chemical environments?

- Aluminum sheets are indeed suitable for usage in harsh chemical environments. Their remarkable resistance to numerous chemicals, including acids, alkalis, and organic solvents, is noteworthy. The formation of a protective oxide layer on the surface of aluminum aids in preventing corrosion. Moreover, aluminum's lightweight nature, durability, and cost-effectiveness have contributed to its widespread use in various industrial applications within harsh chemical environments. Nevertheless, it is essential to acknowledge that the appropriateness of aluminum sheets in particular chemical environments may also be influenced by factors such as temperature, concentration, and duration of exposure to the chemicals. To ensure the proper selection of materials for a given chemical environment, it is always advisable to consult experts or refer to specific chemical compatibility charts.

- Q:What is the maximum temperature that the aluminum sheets can withstand?

- The specific grade of aluminum used determines the maximum temperature that aluminum sheets can endure. In general, most aluminum alloys maintain their structural integrity up to temperatures ranging from 600 to 650 degrees Fahrenheit (315 to 343 degrees Celsius). However, it is crucial to recognize that extended exposure to high temperatures may result in aluminum weakening, deforming, or even melting. Consequently, it is advisable to refer to the manufacturer's specifications or testing data for the particular aluminum grade in order to ascertain its maximum temperature tolerance.

- Q:How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The price of 101 aluminum sheets can vary depending on various factors such as market conditions, demand, and supply. However, generally speaking, 101 aluminum alloy is considered to be one of the most affordable options among aluminum alloys. It is often chosen for its relatively low cost and good overall performance. Compared to other aluminum alloys, especially high-strength alloys such as 7075 or 6061, the price of 101 aluminum sheets tends to be lower. This is because 101 aluminum is a relatively simple alloy with a lower composition of alloying elements, making it less expensive to produce. However, it is important to note that the price differentiation between aluminum alloys can vary depending on current market conditions and specific requirements. Factors such as the thickness, size, and quantity of sheets required can also impact the final price. Therefore, it is always recommended to check with suppliers or manufacturers to get the most accurate and up-to-date pricing information for 101 aluminum sheets compared to other aluminum alloys.

- Q:How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q:Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent due to their malleability and low density.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheets AA1060 Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords