Alloy Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

Features standards and products of our butt welding fittings:

Features of Butt-Welding Reducing Outlet Tees:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Reducing Outlet Tees:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Reducing Outlet Tees:

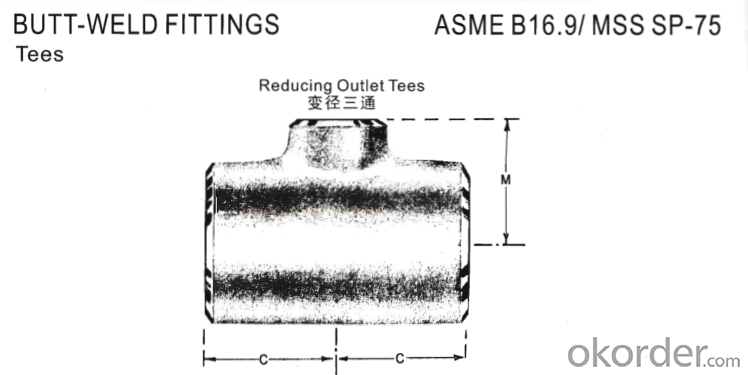

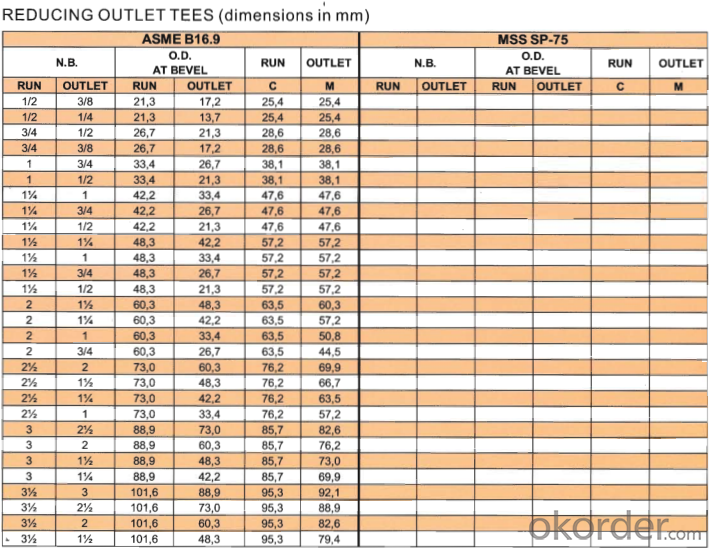

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Reducing Outlet Tees:

Packing of Butt-Welding Reducing Outlet Tees:

FAQ of Butt-Welding Reducing Outlet Tees:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:how far away you can park away from a fire hydrant?

- Brush some flux on the joints (fittings) first. Flux is an acid that etches the surface so the solder will stick.

- Q:Who should the Undertaker face at WrestleMania 29?

- Black Poly Water Line

- Q:I was driving last night, and wasn't paying attention to where I was going in a parking lot and hit and knocked over a fire hydrant I didn't really notice what I did (I thought I just hit the curb) there was no water running to it yet I guess. so I drove away the next day I noticed my bumper was bent and had some paint on it. I know somebody had to'v got my plate can I get in serious trouble for this, if so what?

- Yes, you can fire them. Of course, they have every right to make you pay for the services they have already provided for you. In other words, you can't fire them now and not expect to owe them anything.

- Q:I heard once it was 68% or something.

- Contact a lawyer anyway and ask for advice on what to do and after that the court house should be able to appoint you a lawyer but that might just be if you are arrested another thing u can do is to report it to your company director of HR (human resources) good luck

- Q:I asked my mom if it was safe to go to sleep with the fire still going and she said yes. I'm worried because the fire is just out in the open and I'm afraid that somehow it could start a fire. I want to go to bed because I have a busy day tomorrow catching up on school work, but now I feel like I have to stay up all night until this stupid fire goes out. What should I do? :(

- The easiest solution is to measure the O.D. (outside dimension) of the pipe coming out of the wall, or take the piece you cut off. Go to a plumbing supply store (best) or to a Lowe's or Home Depot. The store salesman will find a pipe with the exact O.D. dimension you measured (to use as a reference only), then match up compression fittings to connect from the wall to a new horizontal piece, then to the p-trap. (What you called a J bend pipe). PVC fittings will be much easier to work with also. Connecting the drain housing to the sink is done using plumber's putty under the lip of the housing and tightening the nut underneath, which will create a waterproof seal. Do not use silicone.

- Q:My grandmother has a vcr that she had me take a look at and all it will do is take the tape in and then eject it right back out. What could be causing this and it is not the tape because we tried several tapes and they all did the same thing. I am just trying to find out if it is worth repairing because it was made in september of 1993 so its like 15 years old but she insists on getting someone to work on and and i just think she should just trash it and buy a vcr and dvd combo. But what ever answers i get i will tell her.

- Try using copper pipe instead of PVC it will hold up better in the long run and if the PVC is running a span of over 4 ft then it gets very shaky. My best advice would be go gt your pipe and fittings, go for it.

- Q:I want to stand a 9' copper column on my patio for decor. It will only be 8' from the house. i dont want it to be a lightning rod, any tips or references would be appreciated. Thanks.

- it only comes in blue, red, white, and black. try a plumbing supply store.

- Q:Who knows what the clamp joint standard is?

- There are a lot of standard for fast mounting clamps.The actual production of the ISO clamp joints seems somewhat different from the standard,

- Q:So,i want to make a Anthony van Leeuwen microscope replica,and i need to make a 1-2 mm glass sphere.I have my torch ready,protective eyewear and gloves,but i am still reluctant to melt glass. Wont it shatter?Any tips on what glass to use?And to prevent shattering?

- The absolute easiest way is to soak overnight with Coca Cola every couple of hour before you go to bed drip a little on each of the fittings, and let it froth and foam use fresh Coke not flat

- Q:1991 gmc jimmyok so when i hit a pothole or go over a speed bump the stuff in the back flies up in ther air and when i drive my other truck its so soft when i hit speed bumps.so i took it in and lesschwab said i dont need shocks but why does it hit so hard?and my stepdads car just started hitting hard like mine and he took it to the same leschwab and they said he didnt need um either i mean u can still bounce the truck but it just hits really hard.

- Galvanized pipe for the water with galvanized fittings, Not brass. Water running through these two unlike metals will cause electrolysis which eventually will cause rust from the galvanized iron pipes. Black iron for the gas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Steel Pipe Fittings Butt-Welding Reducing Outlet Tees

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords