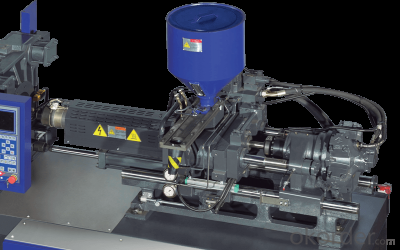

All-Electric High Precision Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of All-Electric High Precision Injection Molding Machines

Introduction

1.Reliable plastic injection machine with servo motor ,equiped with servo motor , closed loop control for pressure and flow .low noise,high precision and energy saving .

We design,manuafcture and supply our own brand of injection molding machine with clamping force ranged.

2.Inject all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, omponents for automotive, household, eletronics, telecommunication, ETC

Advantages&Traits of All-Electric High Precision Injection Molding Machines

Control part:

1.It adopts imported computer for plastic injection machine , with large screen . high definiyion crystal display and human-computer interface in different languages. Through CPU independent control and individual treatment. It has raised the running speed of thr control system and alarming of successive oil temperature , thus I,proving the operating speed of the machine.

2. Closed –loop temperature control system to ensure the accuracy and reliability of the barrel temperature . The functions of cold –proof boot, alarming and parameter memory for the molding, with password protection. The injection and switch are controlled by imported ruler.

Injection part:

1.The excellent chrome , molybdenum and aluminum alloy screw and barrel have undergone the nitrilizing process, applicable to various plastic materials.

2. The injection cylinder(258T advanced) is parallel or balance for both sides of the barrel, so as to ensure the non-deviation of thr nozzle, good sealing and non-leadage. It is equipped with double guide pillar supporting system which can inject under multifarious pressure at various speeds. It also uses one-stop hydraulic pre-injection device.

Hydralic part:

It adopts the imported top quality hydraulic components, proportional control for pressure and flow.

Moulding-adjusment part:

Mold is adjusted by gear controlled by oil motor , the mold can be adjusted automatically in accordance with the setting pressure , which is both convenient and reliable.

Mold part

1.Five –fulcrum crankshaft structure , the mold and bracket structure together,with good rigidity and high-fitting precision, adopting the computerized optimized design. The mold employs finite element analysis, with double pulling and inserting device.

2.Perfroms thefunctions of super sensitive low pressure protection. The mechnical hydraulic and electrical protection have the human safety. The dismounable fill-out hopper can be installed conveniently and automatically.The moveable platen adopts a fixed durable vertical brace that is adjustable. With little friction and balanced dependable moving. Clamp opening is synchro with ejection.

Specification of All-Electric High Precision Injection Molding Machines

Item | Unit | Parameter | ||

Screw no | A | B | C | |

Screw Dia | mm | 38 | 42 | 45 |

Screw LD ratio | 23.2 | 21 | 19.6 | |

Theoretical capacity | cm3 | 209 | 256 | 294 |

Injection weight | g | 190 | 233 | 267 |

Injection Pressure | MPa | 243 | 199 | 173 |

Injection rate | g/s | 100.9 | 123 | 141.2 |

Plasticizing capacity | g/s | 14.7 | 18.2 | 20.6 |

Max. screw speed | rpm | 200 | ||

Clamping force | kN | 1280 | ||

Moving mould distance | mm | 560 | ||

Tie bar spacing | mm | 420×420 | ||

Max.Daylight | mm | 730 | ||

Min. mould thickness | mm | 170 | ||

Ejector stroke | mm | 150 | ||

Ejector force | kN | 41 | ||

Ejector bar amount | 5 | |||

Max.pump pressure | MPa | 17.5 | ||

Pump motor power | kW | 15 | ||

Heating power | kW | 7.5 | ||

External dimension | mm3 | 4500×1600×2100 | ||

Weight | Kg | 5500 | ||

Material cylinder capacity | L | 25 | ||

Oil tank capacity | L | 265 | ||

Package of All-Electric High Precision Injection Molding Machines

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:What are the plastic products stocks?

- Provide land, property, equipment, vehicle rental services.TS: domestic major enterprises to focus Plitt production of automotive modified plastics products, key high-tech enterprise of national torch plan. Currently has five series of more than 300 varieties, with an annual output of 50 thousand tons of production capacity, production of automotive modified plastics in the domestic enterprises in the top, the yield of modified ABS, PC/ABS alloy products ranked first, the yield of modified PP products are also in the forefront. The company provides services for automobile manufacturing, household appliances, electronic information and other enterprises, specializing in high performance plastic composite materials research, production, sales and service, is one of the industry earlier for the automotive industry the most complete enterprise qualification.

- Q:Such as "computer embroidery processes" - Programming - sample preparation, shipment packing production computer

- Process flow of plastic products1. Preparation before moldingA, grain preheating and drying: if the grain is affected with damp, it should be dried;B, insert preheating: in order to reduce the gap between the cooling shrinkage value of metal and plastic, the larger metal insert should be preheated.C, barrel cleaning: when changing the product, changing the raw materials, cleaning cylinder is required.2, injection molding process feeding - plasticizing - injection - holding pressure - cooling - die opening piecesA, feeding: each feeding should be quantitative, in order to ensure uniform plasticization;B and plasticization: the grains are heated to a molten state in a barrel;C and injection: the injection molding machine uses a screw to inject molten plastic into the mold cavity;D, keep pressure: after the mold is finished, maintain the pressure for a certain time;E and cooling: keep cool for a certain time in the mold cavity;F, mold opening parts: mold open, take out the product.3, plastic parts after treatment: plastic parts after treatment:A, remove the fly edge, material handle.B, inspection and packing.

- Q:How much would you like to invest? ThirtyI want to make a wet paper towel and a paper napkin processing factory here. It is specially distributed to hotels, hotels and so onAs the local do not do such packing bag manufacturers, each time from the field of purchase, so I want to do a plastic bag processing plant, so here to consult you. What equipment and materials do you need?

- Do plastic bags of equipment generally have blown film machine, bag making machine and printing machine, film blowing machine 30 thousand on the line, bag making machine and printing machine grade points are many, the price gap is too large, not to say, look at your specific requirements.

- Q:What are the plastic products used in heavy trucks, and how do they form?

- There are several forming methods commonly used. First, calendering calendering for thermoplastics. It is through Plasticating plastic, sent to several groups of parallel arrangement, reverse rotation of the heat roller, by repeatedly calendering products. Production of film or sheet. Two, casting casting use dry plastic. It is soluble in the solvent of plastic, due to weight andspread to continuous operation of the metal belt, become thin layer of uniform thickness, then heating apparatus soft volatile agent, curing products, production of film or sheet.

- Q:Plastic processing process

- The purpose is to beautify the surface of plastic products, usually including: mechanical modification, namely with filing, grinding and polishing process, the removal of parts on edges, burrs, and fixed size; finishing, including coating surface parts, the use of a solvent to surface brightening, covered with patterned thin film surface; colour. Including painting, printing and printing; metal plating, including vacuum coating, electroplating and chemical plating method etc.. Among them, the hot stamping is heated, under pressure, the hot film on the color of aluminum foil (or other pattern film) transferred to the workpiece. Many household appliances and building products, daily necessities and so on use this method to obtain the metal luster or the wood grain and so on the pattern.

- Q:Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q:How is the processing cost of plastic parts calculated? Would you please tell me how to calculate the processing cost of plastic parts? For example, how is the processing fee formed?

- Cost of raw materials, labor costs, mechanical fees, tax increases, plus other

- Q:Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q:Would like to ask a few questions?1, waste plastics need to go through a few devices or steps to become plastic particles2, how much would it cost for the whole set of plastic particles? (I want to get a small wire first)3, if the equipment, plastic material can be any processing?4, is there any pollution in the whole process?.5, how about this prospect this year?Please have experienced predecessors to give some experience

- 3: not for any polypropylene and Juyi plastic processing should be able to use other plastic should not4: the cleaning of this piece in processing will cause two pollution5: This is mainly to see you personally, as the saying goes, peers are different, in general, the plastics industry is OK

- Q:Processing method of PPS plastic

- For housing, structural parts, wear parts and sealing materials, such as: concrete pump casing, pump, valve, bearing, bearing bracket, piston ring and gear, pulley, fan, meter parts, flanges, Wan Xiangtou, counter, leveling. 2, electronic and electrical appliances: PPS for electronic and electrical appliances industry accounted for 30%, it is suitable for high temperature electrical components in the environment temperature higher than 200 DEG C; manufacturing generator and engine point rinse, rinse the electric coil, starter bracket, shield and leaf; on the TV, it can be used for high voltage shell and socket, wiring column and terminal plate; and a relay coil in the electronics industry, manufacturing transformers, resistance of the skeleton and shell, an integrated circuit carrier; using high frequency performance, manufacturing H bobbin and capacitor etc.. Micro electronic components, connectors, connector, socket, coil skeleton, Ma Dake, electromagnetic regulating plate, TV tuner shaft, relay, trimming capacitor, fuse holder, tape recorder, magnetic device and other components. Also used in precision instruments: computers, timers, speed machines, copiers, cameras, temperature sensors, and all kinds of measuring instruments shell and parts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

All-Electric High Precision Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords