Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

1. AUTOMATIC FEEDING SYSTERM

2. ABB BRAND INVERTER

3. RKC BRAND TEMPERATURE CONTROLLER

PE PIPE PRODUCTION LINE EQUIPMENTS FEATURES:

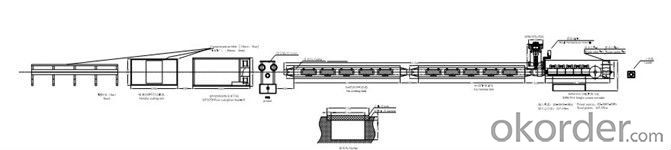

PE pipe production line qingdao benice plastic machinery co.,ltd mainly consists of PE single screw extruder, PE pipe special using mould, PE pipe vacuum calibration water tank, PE pipe drawing machine, PE pipe cutting machine, PE pipe stacker, and the auxiliary machine: SHL200/500 mixer.

PE pipe plastic making machine features:

High speed, high efficiency extrusion single screw extruder is specially designed for extruding PE etc. material, equipped with the lower noise, high speed and hard gear reducer. The Special grooved feeding bush with water cooling system results in increasing compression and filling factors. Specialized screw designs for high output, low melting temperature, good plasticization effection, lower energy consumption.

Spiral diffluence type extrusion die is specially designed for PE extrusion. Unique design of low-pressure inclined flow passage spiral/lattice basket die head, ensures low temperature and high plasticizing extrusion of PE pipes; Special designed die core spiral temperature control, ensures the performance of PE pipes; Multi-layer co-extrusion die offers the advantages of low cost and flexibility of layer structure with different material. it features in easy adjustment and even extrusion, ensures that melting pressure and flux are uniformity, the surface of pipe is smooth and shapely. Skype is benicexiaofei

Plastic PE pipe making machine specifications:

Model | Pipe diameter Range (mm) | Pipe extruder model | Marking- line extruder model | Extrusion speed | Max Output | Total installed power | Dimension |

BAXPEG-50×33-63 | Ø20-Ø63 | BAXSJ-50×33 | BAXSJ-25×25 | 0.3-12 | 120 | 65 | 36 ×2.2 ×2.5 |

BAXPEG-65×33-125 | Ø20-Ø125 | BAXSJ-65×33 | BAXSJ-25×25 | 0.3-12 | 220 | 110 | 56 ×2.2 ×2.6 |

BAXPEG-80×33-160 | Ø63-Ø160 | BAXSJ-65×33 | BAXSJ-30×25 | 0.3-6 | 300 | 150 | 50×2.2 ×2.8 |

BAXPEG-80×33-250 | Ø75-Ø250 | BAXSJ-80×33 | BAXSJ-30×25 | 0.5-5 | 400 | 200 | 52 ×2.2 ×3.0 |

BAXPEG-90×33-400 | Ø160-Ø400 | BAXSJ-90×33 | BAXSJ-30×25 | 0.2-2 | 550 | 280 | 66 ×2.2 ×3.0 |

BAXPEG-90×33-500 | Ø200-Ø500 | BAXSJ-90×33 | BAXSJ-30×25 | 0.1-1 | 700 | 360 | 70 ×2.3 ×3.5 |

BAXPEG-120×33-630 | Ø355-Ø630 | BAXSJ-10×33 | BAXSJ-30×25 | 0.1-1 | 900 | 450 | 72 ×2.3 ×3.5 |

BAXPEG-150×33-1200 | Ø710-Ø1200 | BAXSJ-150×33 | BAXSJ-45×30 | 0.05-0.5 | 1500 | 650 | 80 ×3.0 ×4.0 |

Main Configuration of Plastic Pipe Extrusion Line

Extruder/ Vacuum Shaping part/ Cooling part/ Haul-off Device/ Cutter/ Stirring-up Rack

- Q:I'd like to open a plastic bag factory. How much do I need to buy the equipment?

- It depends on what plastic bags you need to make, and the size and size of the big plastic bags are also crucial. I make plastic bags.

- Q:ABS plastic processing flow

- ABS resin is a three element copolymer developed on the basis of modification of polystyrene resin. A stands for acrylonitrile, B for butadiene, and S for styrene. ABS resin has three components, the comprehensive performance of A can improve the oil resistance, chemical corrosion resistance, which has a certain surface hardness; B ABS showed a rubbery toughness, improve impact toughness; S ABS plastics showed good fluidity, which has a good performance of thermoplastic plastic molding processing. ABS plastic is mainly used in the manufacture of instruments, instruments, household appliances, telephones, TV sets and so on. ABS plastic is used to make metal luster, and ABS is used instead of metal. Our factory produces various types of refrigerator liner and all kinds of plastic products, ABS injection products accounted for more than 88% of the total refrigerator plastic products

- Q:How do we calculate the cost?

- Four major matters needing attention in investment of recycled plasticsPlastic recycling is a sunrise industry, the country, not only the effective utilization of resources and protect the environment, reduce the white pollution, from 2004 recycled plastics market, considerable benefits, as a new way of friends, is the author contact situation (editor's note), there are many aspects should be prepared in the first period, not to fight the battle without. The main problems are concentrated in the following aspects:1, blind follow-upAccording to the renewable materials market in 2004 prices, had been recycled most of the people have a better income, as for friends, in the test stage, on the surface has the advantages of simple process, low equipment investment, the product basically in short supply, technology content is not high, ordinary people can do at the same time, the raw material is us around the most familiar things, everywhere, everywhere can buy. Rough calculation, such as waste 2000 yuan can receive, the product can sell 4000 yuan, absolutely profitable.

- Q:Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- In contrast to many manufacturers of plastic processing equipment, more important is environmental protection, there is calm in the future, if you want to buy the equipment you can go to Laizhou city to take a look at the field, there are a lot of home doing well,

- Q:What kind of machine is needed for the production of plastic products?

- Seventy thousand or eighty thousand an injection molding machine, a crushing machine, a drying machine forty thousand or fifty thousand, workshop, rent, labor, water and electricity to ten thousand months Duoliangwanyi, mold materials, another operator, of course cost large scale is low.

- Q:What machines do you need? Where can I get the raw material? Thank you

- This kind of enterprise does not need too much liquidity, equipment and machinery to the company of large equipment manufacturing orders, raw materials can be recommended if in order to the factory machinery, because this kind of raw material enterprises generally left in the information equipment manufacturing enterprises, facilitate the development of business.

- Q:What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q:Is it gear oil or general oil?Inside the old oil is relatively thin, the new gear oil is relatively thick. Can you add?.Please point out.Should we add "ordinary gear oil" or "hyperbolic"?

- Gear oil should be added, and the old one may be flooded or originally not gear oil.Regular is ok.

- Q:The plastic bottle processing plant needs those machines

- Crusher what online, many to transfer technology and plant equipment, you can check for yourself

- Q:It's a small plastic shell for the processing plug! How much is the small injection molding machine 100Which great God knows what equipment a small plastic shell needs?! It's a small plastic shell for the processing plug! How much is the small injection machine?! Where does Wuxi sell injection molding machine?!

- This is the general plug mold practice. Buy vertical injection molding machines. This machine is usually divided into two columns and 4 columns. The price is about 10000.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic PPR/PE Pipe Production Machine/Water PE Pipe Manufacturing Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products