AC Driver China Best Selling VFD Frequency Drive 3 phase 380V 11kw

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

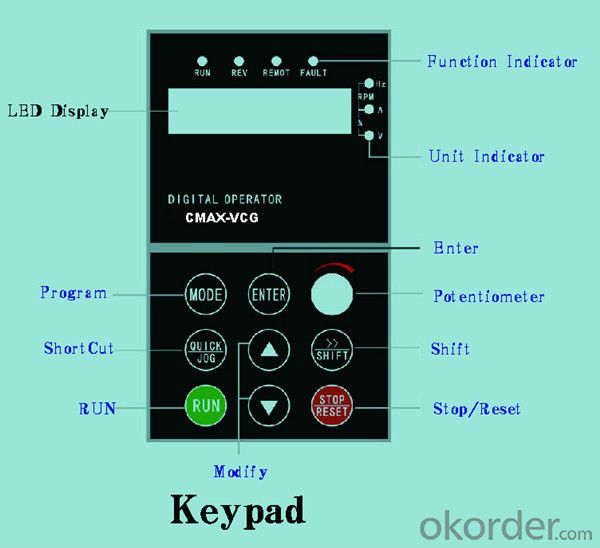

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

- Q:What's the difference between universal inverter and fan pump converter?

- Fan and pump load:In a variety of fans, pumps, oil pumps, with the rotation of the impeller, the air or liquid within a certain speed range of resistance is roughly proportional to the speed of the 2 side of the n. As the speed decreases, the torque decreases by 2 times the speed. The power required for this kind of load is proportional to the 3 power of the velocity. When the required air volume and flow rate are reduced, the frequency and speed of air flow can be regulated by the frequency converter, so the energy can be saved substantially. Because the power required at high speed increases with the speed, and is proportional to the speed of the three side, so the fan and pump load should not be used in the ultra power frequency operation

- Q:How can I learn the converter well?

- Secondly, you can also take part in some frequency converter, PLC training institutions, in order to improve themselves, through training to enhance their skills, this is a way to quickly learn.

- Q:Not to say that the inverter speed is mainly down frequency, how can I see the frequency rise to 60HZ, so that the three-phase motor is not more than the rated speed?

- Frequency rising problem of frequency converter;Voltage matching; the rated voltage of the converter is in line with the rated voltage of the load.Current matching; ordinary centrifugal pump, the rated current of the converter is in line with the rated current of the motor. For special loads, such as deep water pumps, it is necessary to refer to the motor performance parameters and determine the current and overload capacity of the inverter with maximum current.Torque matching; this situation may occur when a constant torque load or a deceleration device.

- Q:High-voltage converterGeneral inverterPump frequency converterEngineering frequency converterCould you tell me some frequency converter according to the class?

- Specific answer to your question: 1, high voltage inverter: This is based on the input voltage level terms. Generally speaking, 10KV is more than 6KV voltage high voltage frequency converter, 1140V, 3300V in general is medium (some people also called it the high voltage level of 380V, 660V), 480V, commonly called the low-voltage inverter; 2, pump inverter: This is according to the type of application in terms of. Fan pump inverter mainly refers to the frequency converter used to drag fans, pump load, the main feature is light load, simple application.

- Q:What are the parameters of the frequency converter? Thank you

- That is to say, the upper and lower amplitudes of the output frequency of the inverter. Frequency * * is to prevent misoperation or external frequency set signal source failure, resulting in the output frequency is too high or too low, in order to prevent damage to a device protection function. In the application, according to the actual situation can be set. This function can also be used as a speed limit, if the conveyor belt, the conveying material is not too much, to reduce the mechanical and wear belts, be driven by inverter, and the inverter upper frequency settings for a particular frequency, so it can make the belt conveyor running on a fixed low speed work

- Q:Surface grinder can add frequency converter, what are the advantages and disadvantages?

- SAJ inverter in the industry's specific applicationZhejiang Kanmen machine tool factory mainly produces all kinds of economic type simple NC machine, due to the higher failure rate of electromagnetic clutch speed regulation, realize VVVF system has more advantages, so using VVVF inverter to achieve the three. The details are as follows:

- Q:1, the frequency converter to the motor cable should be shielded cable? 2, whether there are specifications?

- Do not use shielded cables have several conditions: the first is from the inverter to motor wear long steel pipe laying cable. Second is the frequency converter to the motor cable line routing (cable bridge, cable ditch), there is no analog signal cable or other weak signal cable. Otherwise, from the debug runtime, if the inverter cable cable line motor and analog signal very close, even if the analog signal shielded cable control cable when the motor running is still very obvious interference of analog signals, especially large power motor.

- Q:What's the function of this brake unit?

- When the motor is fast stopping, the motor will feedback the energy to the converter, causing the DC bus voltage to rise or even damage the IGBT. Therefore, it is necessary to use the braking unit to save the part of the energy to protect the converter.Inverter braking a lot, can refer to:

- Q:Can a power converter be used in a motor with small power? Will it burn the motor?

- Large power converter can be used in small power motors, as long as the motor nameplate parameters, in the inverter motor parameters can be set, so that the inverter can provide the right protection.And。 Selection of frequency converter capacity, generally greater than the power of the motor more than one file.

- Q:Where is the difference between soft starter and converter?

- Are two completely different uses of the product. The inverter is used for the need for speed place, its output voltage and frequency change not only change; the soft starter is actually a regulator for motor starting, output voltage and frequency change not only change. Inverters have all of the soft starter functions, but they cost much more than soft starters and have a much more complex structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AC Driver China Best Selling VFD Frequency Drive 3 phase 380V 11kw

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords