VFD Frequency Drive 3 phase 220V /380V

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

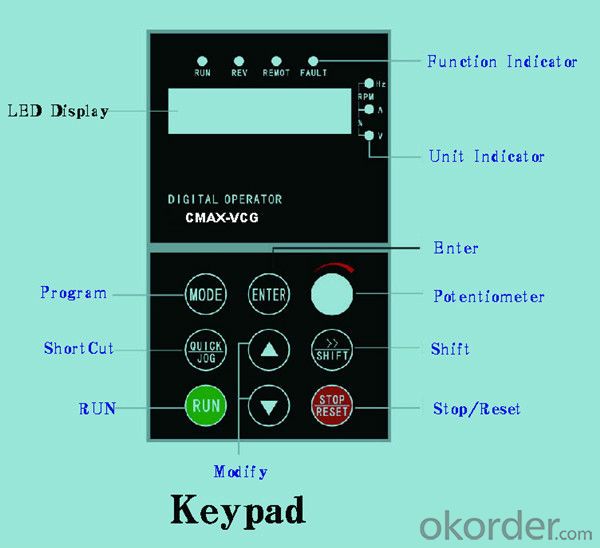

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:I am in control of the equipment: the same mechanical movement, this needs a motor drive, a frequency converter drive. Now it's due to the mechanical location: buy two units of the same motor. Can you use a converter in parallel to drive it? Please point out! Thank you (frequency converter: the power of Schneider is equal to the sum of two motors)

- It is possible to control more than one motor with 1 inverters, which are controlled by the transmission track motors in general metallurgical projects, but should pay attention to the following points before operation:1 the choice of inverter power (the power converter must be greater than or equal to the sum of the motor power)2, the choice of control mode (usually with VF control, no speed feedback open-loop control)3 parameter settingsA sets the current value of the motor to the sum of the current values used by all motorsB sets the voltage and frequency of the motor, which is the voltage and frequency value of an electric motor

- Q:The frequency converter works with sharp noises. What's the process of converting electrical energy into mechanical energy?. The mechanism of sound making. Thank you

- Frequency converter (Variable-frequency, Drive, VFD) is the application of frequency conversion technology and microelectronics technology, by changing the power supply frequency of the motor to control AC motor power control equipment.

- Q:How to maintain the frequency converter will not damage, or regular maintenance?

- The correct use method and reasonable maintenance can extend the service life of the inverter to a certain extent. The common maintenance methods of the inverter are cleaning the air filter, cooling the air duct and the interior dust. Check whether the screws, bolts and plug are loose, the input and output reactor ground and interphase resistance is short circuit, the normal should be more than tens of megabytes of europe. The conductor and insulator are corrosion phenomenon, if in time to wipe clean with alcohol.

- Q:What's the role of an electric car, the part of a traditional car?

- The main advantage of inverter products in electric vehicles lies in:1, reliability: three heavy over-current protection, three heavy voltage protection, three heavy drive protection, ensure the motor controller reliable and stable operation.2, the control strategy is superior: the motor controller adopts vector control technology, which has the advantages of superior performance and high reliability. It is suitable for AC asynchronous or permanent magnet synchronous motors;3, the large capacity output capability: the output end of the motor with no gearbox or reducer, greatly reduces the noise, fault point and mechanical drive system control mode is simple, cost saving, high reliability, good stability of vehicle operation;4, the power performance is good: acceleration performance (0 ~ 15 seconds 50km/h), more good economic performance (0.9 degrees /km @40km/h);5, fault diagnosis and treatment: in order to improve the reliability of the whole vehicle, motor control system must have the function of fault diagnosis, and can save the trouble, convenient after analysis, also through the diagnostic ports can be implemented online debugging motor controller and recording various operating curve facilitates optimization of the whole control system;6, efficient braking energy recovery: give full play to the advantages of pure electric vehicle powertrain system, improve energy utilization, motor control system must have the brake energy recovery function.7, simple: motor controller quality is reliable, and light weight, easy to layout, wiring, maintenance convenience and so on, the industrialization prospect is very good.

- Q:What does "frequency" in household appliances mean?

- The air conditioner in Japan is gradually changed from pure PWM control to PWM ten PAM mixed control mode. The speed is controlled by PWM, U / F to maintain; when the speed exceeds a certain value, the system will adjust the fixed at the maximum value near, by changing the DC chopper on duty LL, improve the inverter input DC voltage, so as to keep the inverter output voltage and speed is proportional to the area, said PAM area

- Q:What does Ro1c mean on a converter?

- RO1C is the common terminal and the RO1A is normally closed, and the RO1B is normally open. The set of contacts is the output signal that is ready to run. That is, the self-test of the converter is completed and the output signal of the relay can be operated.

- Q:What does a frequency converter do?

- What is the starting current and starting torque of the motor when the inverter is in operation?Using frequency converter operation, with the acceleration of the motor, accordingly improve the frequency and voltage, the starting current is limited to 150% rated current (according to the type of machine is 125%~200%). The starting current is 6~7 times of direct starting with the mains frequency power supply, so the mechanical and electrical impact will be produced. It can start smoothly with frequency converter (longer starting time). The starting current is 1.2~1.5 times the rated current, the starting torque is 70%~120%, the rated torque; for the inverter with automatic torque enhancement, the starting torque is above 100%, and the full load can start.

- Q:What is the difference between SIEMENS inverter and built-in filter?

- SIEMENS built-in filter optional three. Class a EMC filter. B class EMC filter. LC/ sine filter.Power 110KW to 250KW converter, optional external or built-in level a filter,The power 7.5KW to 15Kw converter, in addition to additional B class EMC filter, can be equipped with a class EMC filter.The LC/ sinusoidal filter can effectively suppress the rise of voltage and capacitance charge / discharge current in the variable frequency drive. But there are many restrictions: only V/F is allowed. FCC control mode. To comply with the 15% drop capacity, the output frequency limit is 150HZ, and only allowed to operate at the 4KHZ pulse frequency. In operation and debugging, the LC sinusoidal filter must be connected to the motor.

- Q:A control panel I received a photoelectric switch, through the 232 interface connected to the computer, control with a 220V power supply board, computer and inverter when the inverter after the start of the photoelectric switch either do not work or turn off the flash chaos, frequency converter or 232 line open photoelectric switch will be back to normal work. In addition, when the photoelectric switch is powered separately, if the ground wire is connected to the control board, the photoelectric switch does not work. Excuse me, is this interference from the power cord? How to solve?

- Isolation of interference: the so-called interference isolation is the separation of the source of interference from the susceptible part from the circuit so that they do not generate electrical contact. Usually in the power supply and controller and transmitter amplifier circuit, in the power line using isolation transformer, so as to avoid conduction interference, power isolation transformer can use noise isolation transformer.

- Q:How does the frequency converter change the voltage and change the speed of the motor?

- The frequency converter regulates the speed of the motor, mainly by changing the frequency. The frequency determines the synchronous speed of the motor, and the speed of the motor can be lowered by reducing the frequency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

VFD Frequency Drive 3 phase 220V /380V

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products