Frequency Inverter Single-phase 220V class 185KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

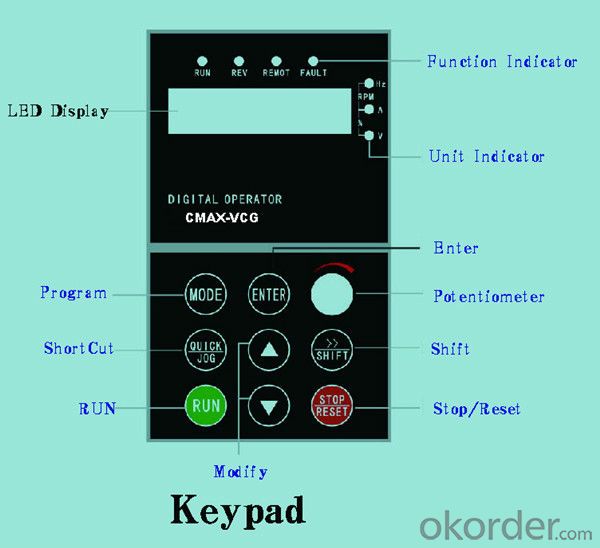

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

- Q:What is frequency conversion? What is the function of frequency converter?

- Frequency conversion:1, the frequency conversion is to change the power supply frequency, thus adjust the load, play a role in reducing power consumption, reducing the loss and prolonging the service life of the equipment. Frequency conversion.2, the core of frequency conversion technology is frequency converter, through the power frequency conversion to achieve automatic adjustment of motor speed rate, the fixed frequency of 50Hz is changed to 30 - 130 Hz frequency. At the same time, the utility model makes the voltage range of the supply voltage reach 142 - 270V, and solves the problem that the voltage of the power grid is unstable, which influences the work of the electric appliance. The technique of alternating current control by changing the frequency of alternating current is called frequency conversion technology.

- Q:At the base block Yaskawa inverter is what reason?

- Garbage in Yaskawa signal board on the small line contact oxidation, look good, this is a kind of weak signal, and for safety relay is not the safety loop at high levels in a small line short circuit, 1000 Yaskawa A factory is shorted for a long time have blocked the oxidation base

- Q:Heating inverter commissioning steps

- The no-load connection test of the frequency converter will connect the grounding terminal of the frequency converter to the ground 1. 2 the power input terminal of the frequency converter is connected to the power supply through the leakage protection switch. 3 check the frequency converter display window factory display is normal, if not correct, should reset, or request exchange. 4 familiar with the operation key of frequency converter. The inverter has run in general (RUN) and stop (STOP), programming (PROG), P (DATAPENTER), the data confirm the increased (UP, 3), reduce (DOWN, 6) and other key definitions of different inverter operation keys are basically the same. In addition, some inverters also monitor (MONITORPDISPLAY), reset (RESET), inch movement (JOG), shift (SHIFT) and other functional keys.

- Q:Today, I was asked the question, and I also brought it to you to share the following Oh!

- Inverter inside the circuit is inverterIt is a control of communication -- direct current -- CommunicationDC alternating current is called inverter

- Q:What is the main harmonic produced by a transducer? How about the degree?

- From the structure point of view, the inverter can be divided into indirect frequency conversion and direct frequency conversion of two major categories. The indirect frequency conversion turns the power frequency current into DC through the rectifier, and then converts the DC to the controllable frequency AC through the converter. The direct frequency converter transforms the power frequency exchange into the controllable frequency exchange, without the intermediate direct current link. Each phase is a reversible circuit in which two thyristor rectifier devices are antiparallel. The two groups of positive and negative switches are switched by a certain period, and the alternating voltage is gained on the load. The amplitude of the U0 is decided by the control angle of each rectifier device, and the frequency is determined by the switching frequency of the two sets of rectifier devices, and the frequency of the U0 is determined by the switching frequency of each rectifier unit. At present, more or more inter frequency converter.

- Q:What does "EPCU" mean in a frequency converter?

- This is the frequency converter BlueOcean Huateng, they said this code external signal interference, you are not the power line and the signal line to go ah, check the external line, then no problem on the phone to the factory

- Q:If you don't plug in the PG card, do you use PLC's PID control?Plug in the PG card and the PLC PID control, which is reliable and precise?

- Using PG card of frequency converter to realize closed loop vector controlFor example, vertical motion loads, such as cranes and elevators, require closed-loop vector controlIn this case, the frequency converter must install the PG card, and the encoder signal will be connected to the PG card, using the frequency converterPID instruction.In this application, the PID function module of PLC can not realize the vector control function.

- Q:Application of ABB frequency converter

- When the motor is powered by an industrial frequency power supply, the current increases when the voltage drops; for the inverter, if the voltage drops when the frequency drops, then does the current increase?When the frequency drops (low speed), if the output is the same power, the current increases, but the current remains almost constant under a certain torque.

- Q:The frequency converter is in use suddenly the speed reduces, then the debugging is out of control, how to do?

- Overvoltage prevention measures: due to over-voltage causes are different, so the countermeasures are not the same. For overvoltage in parking, if there is no special requirement for parking time or position, it can be solved by using extended frequency converter, deceleration time or free parking. The so-called free parking, that is, the frequency converter will switch off the main switch, so that the motor free sliding stop. If the parking time or parking position have certain requirements, then the DC brake (DC brake) function can be used

- Q:How does the frequency converter change the voltage and change the speed of the motor?

- N = 60f/PN is the turn speed, F is the frequency, and P is the magnetic pole logarithm of the engineBy the formula: frequency and speed is proportional to, so the inverter can change the speed of the motor

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Frequency Inverter Single-phase 220V class 185KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords