China best selling VFD Frequency Drive 3 phase 220V 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

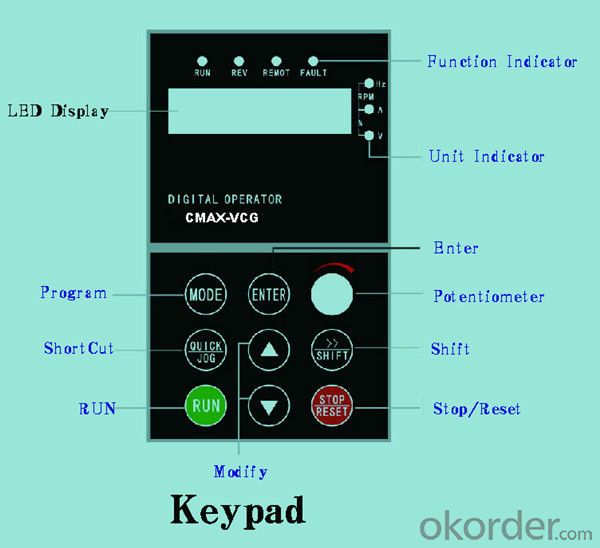

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q:The frequency converter works with sharp noises. What's the process of converting electrical energy into mechanical energy?. The mechanism of sound making. Thank you

- There is a sharp sound can only prove that you have problems with frequency conversion, frequency conversion stable operation can only hear the sound of the fan slightly. Although we are engaged in frequency conversion, but let me tell you this mechanism, really can not say, you can use frequency conversion, and play to his limit, have been very difficult.

- Q:How do two inverters synchronize?

- One potentiometer is used to control one of the inverters, and then the analog output of the inverter is used to control another inverter, and a potentiometer is added to the middle of the converter to adjust the proportion.

- Q:Can 220V use frequency converter to drive three-phase motor with 380V?

- The use of motor, if the star is connected to the corner of the connection can be, and if it is angle, then there is no way, and then the power of the motor will be reduced by about 4/10.

- Q:Why does the frequency change when the frequency converter regulates the frequency?

- Because the product of three-phase asynchronous motor stator phase voltage and frequency and flux is proportional to the frequency when the downward adjustment, if the sustain voltage is constant, the flux must be increased, this will cause the main magnetic saturation excitation current passing, the surge in motor damage.As a result, the voltage is usually adjusted down proportionally as the frequency is lowered down.However, when adjusting the frequency, the voltage is not adjustable in order to avoid the excessive voltage damage of the motor. Therefore, in the use of frequency converter overclocking motor, the magnetic flux will decline, the motor output torque characteristics will move to the left.

- Q:What's the role of an electric car, the part of a traditional car?

- The main advantage of inverter products in electric vehicles lies in:1, reliability: three heavy over-current protection, three heavy voltage protection, three heavy drive protection, ensure the motor controller reliable and stable operation.2, the control strategy is superior: the motor controller adopts vector control technology, which has the advantages of superior performance and high reliability. It is suitable for AC asynchronous or permanent magnet synchronous motors;3, the large capacity output capability: the output end of the motor with no gearbox or reducer, greatly reduces the noise, fault point and mechanical drive system control mode is simple, cost saving, high reliability, good stability of vehicle operation;4, the power performance is good: acceleration performance (0 ~ 15 seconds 50km/h), more good economic performance (0.9 degrees /km @40km/h);5, fault diagnosis and treatment: in order to improve the reliability of the whole vehicle, motor control system must have the function of fault diagnosis, and can save the trouble, convenient after analysis, also through the diagnostic ports can be implemented online debugging motor controller and recording various operating curve facilitates optimization of the whole control system;6, efficient braking energy recovery: give full play to the advantages of pure electric vehicle powertrain system, improve energy utilization, motor control system must have the brake energy recovery function.7, simple: motor controller quality is reliable, and light weight, easy to layout, wiring, maintenance convenience and so on, the industrialization prospect is very good.

- Q:What does "frequency" in household appliances mean?

- The air conditioner use frequency, enlarge the working range of the compressor, the compressor does not require intermittent running can be realized in cold and warm control, to reduce power consumption due to temperature changes, eliminate discomfort. In recent years, the new type of air conditioner has adopted brushless DC motor to realize variable frequency speed regulation, and its energy-saving effect is about 10% - 15% higher than that of AC asynchronous motor frequency conversion. In order to further improve the efficiency of the device,

- Q:What is called vector converter?

- Vectors and vectors are mathematical methods of vector (vector) analysis, both of which are of the same concept

- Q:What is the difference between SIEMENS inverter and built-in filter?

- The filter is used for electromagnetic interference protection. Not only for the protection of electrical equipment, but also for the use of environmental protection. Inverter application environment is very extensive. Industry, light industry, commerce, civil, etc.. So the level of electromagnetic protection is also different.By the way。 If you disconnect the converter. See a coil on a board. That's the built-in filter. If you don't have it, you don't have that coil.

- Q:A control panel I received a photoelectric switch, through the 232 interface connected to the computer, control with a 220V power supply board, computer and inverter when the inverter after the start of the photoelectric switch either do not work or turn off the flash chaos, frequency converter or 232 line open photoelectric switch will be back to normal work. In addition, when the photoelectric switch is powered separately, if the ground wire is connected to the control board, the photoelectric switch does not work. Excuse me, is this interference from the power cord? How to solve?

- Isolation of interference: the so-called interference isolation is the separation of the source of interference from the susceptible part from the circuit so that they do not generate electrical contact. Usually in the power supply and controller and transmitter amplifier circuit, in the power line using isolation transformer, so as to avoid conduction interference, power isolation transformer can use noise isolation transformer.

- Q:What is the function of a frequency converter on an electric motor?

- Frequency converter integrates high voltage, high power transistor technology and electronic control technology, and has been widely used. The role of frequency converter is to change the frequency and amplitude of AC motor power supply, thus changing the period of its moving magnetic field, to achieve the purpose of smooth control of motor speed. The inverter speed control, makes the complex simple, most of the original work can only be done by a DC motor instead of frequency converter + AC squirrel cage induction motor, reduce the volume, reduce the maintenance rate, to a new stage of development of the transmission technology

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China best selling VFD Frequency Drive 3 phase 220V 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords