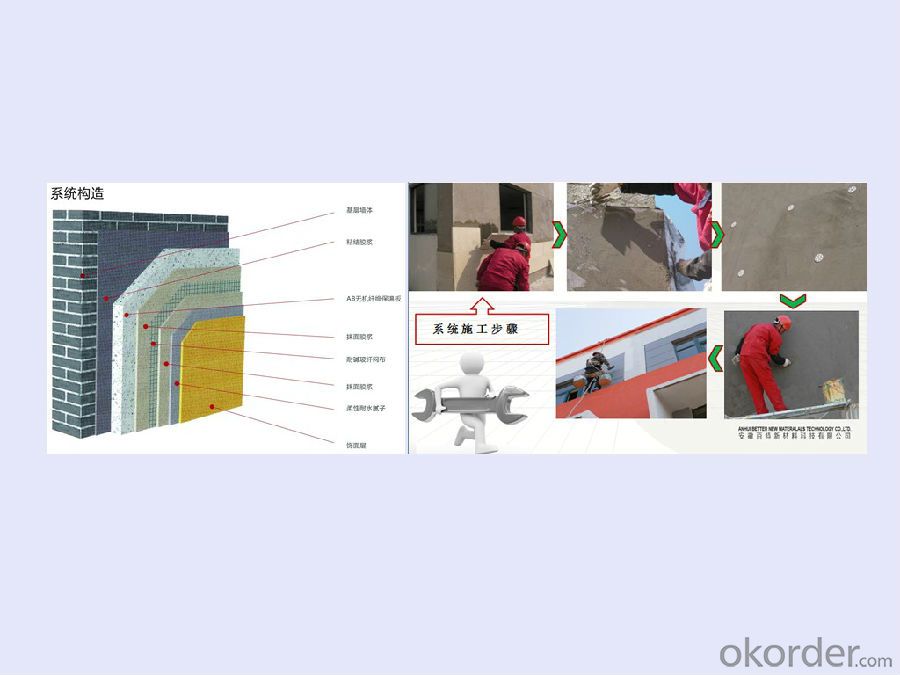

AB inorganic fiber vacuum insulation board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction:

AB inorganic fiber insulation board is an insulation material that base on the Nano poro-us adiabatic principle, which comprehensive performance is outstanding and far beyond c-onventional insulation materials. The product is mainly compounded of ultrafine inorganic-c fibers, has Class A fireproofing, low thermal conductivity, convenient construction and more superior properties.

Range of application:

New construction, renovation, expansion of residential buildings, public buildings, and ind-ustrial buildings, where require insulation in winter or summer.

Feature:

Class A fireproofing, safety and reliability

Excellent insulation property

Great tensile, compressive strength

Good compatibility with the main structure, having same lifetime with the building

Green environmental inorganic insulation materials.

Superiority:

Advantage Ⅰ

Made from inorganic material, class A fire-proofing, noncombustible

Advantage Ⅱ

Superior thermal insulation property, thermal conductivity below 0.008W / (m·k), energy-saving effect is prominent

Advantage Ⅲ

Insulation effect is 3-8 times better than conventional insulation materials, it also means the

Insulation thickness is just one-eighth to one-third of the traditional insulation materials.

Advantage Ⅳ

Inorganic, non-toxic core materials, low-power, zero-emission process, no gas emission, no wate-r emission, the product is an environmentally friendly, low-carbon insulation material.

Advantage Ⅴ

Lighter, easier to transport and carrying, simplify construction technique-s, good paste effect.

Parameter:

Original strength≥1.0

Strength after soaking≥1.0

- Q:Does rock wool board refer to the glass wool ?

- The difference between rock wool and glass wool 1. same raw material, 2, same products performance, the unit weight of glass wool is lower than rock wool, less slag ball, low heat conductivity coefficient, good fiber tenacity, and the using temperature of rock wool is about 600 degrees centigrades, glass wool is about 260 degrees centigrades, 3, products application: glass wool is used for the thermal insulation parts below 200 degrees centigrades,such as construction or low temperature pipe thermal insulation, rock wool is used in thermal insulation parts under 450 degrees centigrades, such as high temperature heat pipe or electric power equipment thermal insulation.

- Q:Glass wool and pef air conditioning insulation material, which one is better?

- It's all right to use rubber and plastic, PEF or glass wool, but it is not recommended to use glass wool which has poor waterproof effect, and try to use rubber! Select the appropriate thickness according the local winter temperature, or it will be frozen if it is too thin in winter.

- Q:Are rubber and plastic thermal insulation material and glass wool in air conditioner energy-saving materials ?

- They almost are.

- Q:does the glass wool can be used as building materials?

- it has been banned in use and the succedaneum material is rock wool.

- Q:If the glass wool is used for thermal insulation outside seamless steel tube, should the pipe be rust-proof and sprayed paint?

- Rust-proof treatment must be done. Without special requirements, you can use epoxy rustproof paint for basic protection. For high demands, you should use zinc anti-corrosion paint.

- Q:Glass wool products can be used for insulation layer

- Glass wool can be sound-absorbing

- Q:What kind of glass wool pipe is this? Where is it sold?

- I own a glass wool plant and you can contact me if you need something.

- Q:Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- If the long-term working temperature is higher than 200 ℃, glass wool is not suitable. Weinai thermal insulation blanket is a good piping insulation material. Besides, glass wool has better thermal insulation property than rock wool, but poorer temperature resistance.

- Q:How does the glazed wall in the living room fixed? The top surface of the glazed wall is mineral wool board.

- Fix it with the structure from left to right and up and down.

- Q:What's the performance and difference of rock wool and glass wool fireproofing material?

- Rock wool and glass wool belong to Class A fireproofing rating, secondly, rock wool can endure high temperature of 800 degrees, glass wool high temperature of 450 degrees, again,unit weight of rock wool is relatively heavier and unit weight of glass wool is lighter, finally, glass wool has better waterproof performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AB inorganic fiber vacuum insulation board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords