AA1xxx Coated Aluminum Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA1xxx Coated Aluminum Coils Used for Construction Description

AA1xxx Coated Aluminum Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1xxx Coated Aluminum Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1xxx Coated Aluminum Coils Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

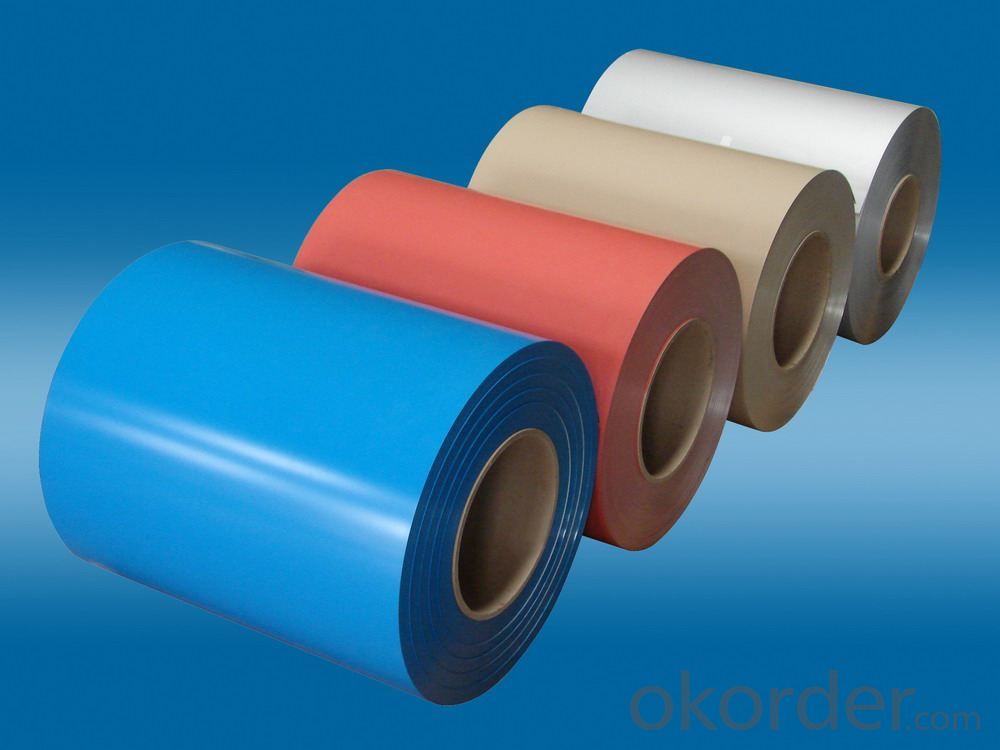

3.AA1xxx Coated Aluminum Coils Used for Construction Images

4. AA1xxx Coated Aluminum Coils Used for Construction Specification

Alloy | AA1xxx |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5. FAQ of AA1xxx Coated Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- Yes...All Aluminium Macbooks are now turned to Macbook Pros. So might want to try the Mid 2009 white macbook or you have to go with 13 Macbook Pro... vist www.parithi for details..

- Q:Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q:What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q:I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- Fiberglass Bass Boats

- Q:Are 101 aluminum sheets suitable for outdoor applications?

- Indeed, outdoor applications can benefit from the suitability of 101 aluminum sheets. This alloy, widely favored, boasts exceptional resistance to corrosion, rendering it an optimal choice for outdoor settings frequently subjected to moisture, sunlight, and similar factors. Moreover, 101 aluminum exhibits solid strength and durability, enabling it to endure diverse weather conditions and physical strains. As a result, it finds extensive use in outdoor projects, including siding, roofing, gutters, and outdoor signage.

- Q:Can the aluminum sheets be used for manufacturing food packaging?

- Yes, aluminum sheets can be used for manufacturing food packaging. Aluminum is a popular choice for food packaging due to its various properties. It is lightweight, resistant to corrosion, and has excellent heat conductivity. These qualities make it suitable for preserving the freshness and quality of food products. Additionally, aluminum is impermeable to light, moisture, and oxygen, which helps in extending the shelf life of food. Furthermore, aluminum sheets can be easily molded into different shapes and sizes, allowing for customized packaging solutions. Overall, aluminum sheets are commonly used in the food packaging industry due to their versatility, durability, and ability to maintain the safety and integrity of food products.

- Q:What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available on the market. These include: 1. Plain Aluminum Sheet: This is the most basic form of aluminum sheet, without any additional finishes or coatings. It is commonly used for general applications where appearance is not a major concern. 2. Painted Aluminum Sheet: This type of aluminum sheet is coated with a layer of paint or resin, which provides additional protection against corrosion and enhances the appearance of the sheet. It is often used for decorative purposes or in applications where aesthetics are important. 3. Anodized Aluminum Sheet: Anodizing is an electrochemical process that creates a durable and corrosion-resistant surface on the aluminum sheet. Anodized sheets have a uniform finish and are available in various colors. They are commonly used in architectural applications, such as building facades or interior design elements. 4. Perforated Aluminum Sheet: This type of aluminum sheet has small holes or perforations throughout its surface. It is often used in applications where ventilation, filtration, or aesthetics are important, such as in decorative screens, speaker grills, or air diffusers. 5. Embossed Aluminum Sheet: Embossing is a process that creates raised patterns or textures on the surface of the aluminum sheet. It adds visual interest and can also improve the sheet's strength and rigidity. Embossed aluminum sheets are commonly used in architectural or decorative applications. 6. Clad Aluminum Sheet: Cladding involves bonding a layer of aluminum to another material, such as stainless steel or copper, to combine their properties. Clad aluminum sheets are used in applications where the benefits of both materials are required, such as in the construction of heat exchangers or cookware. These are just a few examples of the different forms of aluminum sheet available. Each type offers unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, aerospace, and more.

- Q:How do aluminum sheets perform in terms of thermal insulation?

- Aluminum sheets have poor thermal insulation properties. They conduct heat very well, which means they are not effective in preventing heat transfer between different areas or maintaining a consistent temperature.

- Q:Can aluminum sheets be used for pharmaceutical cleanrooms?

- Indeed, pharmaceutical cleanrooms can make effective use of aluminum sheets. Aluminum, known for its exceptional qualities, is a widely employed material in cleanroom construction. Its lightweight nature, durability, and resistance to corrosion make it ideal for establishing and maintaining a hygienic and uncontaminated environment. Within the cleanroom, aluminum sheets can serve various purposes including wall and ceiling panels, as well as other surfaces. These sheets are easy to clean and sanitize, guaranteeing a contamination-free pharmaceutical cleanroom. Furthermore, aluminum's non-porous nature prevents the growth of harmful bacteria and fungi. Consequently, aluminum sheets present a fitting choice for the construction of pharmaceutical cleanrooms.

- Q:Can aluminum sheets be textured or patterned?

- Indeed, it is possible to texture or pattern aluminum sheets. Numerous techniques exist for achieving desired textures or patterns on aluminum sheets, including embossing, engraving, or etching. These methods entail modifying the surface of the aluminum sheet to achieve the desired texture or pattern. Furthermore, aluminum sheets can also be coated or painted with various finishes or colors to attain a specific textured or patterned appearance. In summary, by employing appropriate techniques and processes, aluminum sheets can be extensively transformed and personalized to possess a diverse array of textures and patterns.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA1xxx Coated Aluminum Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords