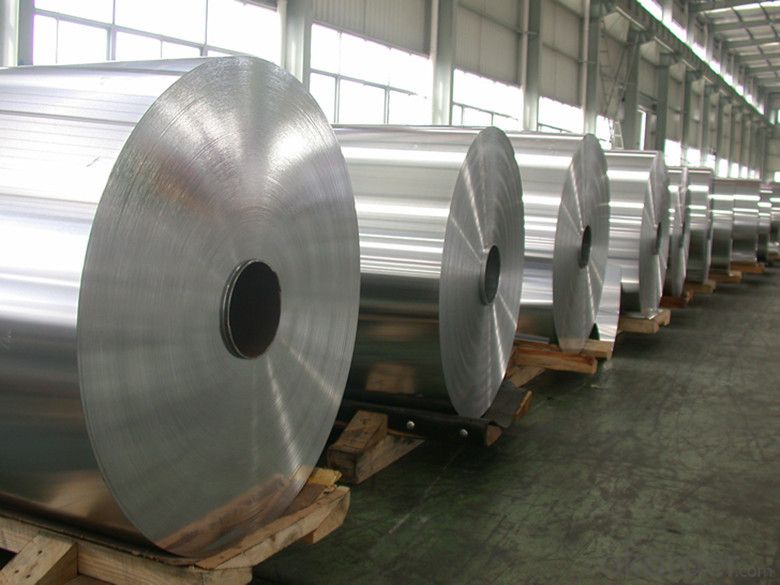

5083 Aluminium Coil And Foil Strip Household Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.20 years OEM service, custom order available

2.Excellent barrier

3.FDA, SGS

Material: Different materials available for option - Food grade

Glossy finish: PET/AL/PE, PET/VMPET/PE, OPP/VMPET/PE

Transparent: PET/PE, NY/PE,PET/CPP

Matte finish: OPP/AL/PE,PET/CPP, PET/NY/PE

More Details

1. Original factory price, high quality, fast delivery.

2. ISO9001:2008; ISO14001:2004.

3. Material: PET/ AL/ PE; NY/AL/PE,OPP/CPP,PE/PET.etc.

4.Moisture proof, oxygen barrier, nontoxic.

5. Available in different material to suit for different products’ package

6.Customized structures, size, styles are welcome.

FAQ

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe

,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What will affect the performance of the aluminum ingot in the process of casting?

- In our daily industrial raw materials called aluminum ingot, according to the national standard (GB/T1196-2008) should be called "remelting with aluminum ingot", but we are used to "aluminum ingot"". It is with the alumina cryolite produced by electrolysis.

- Q:Are aluminum sheets suitable for chemical filtration applications?

- Aluminum sheets prove to be a fitting option for chemical filtration applications. Renowned for its outstanding corrosion resistance and durability, aluminum emerges as a trustworthy selection for chemical filtration systems. It diligently sieves out impurities and contaminants across diverse chemical procedures, encompassing the separation of solids from liquids and the elimination of hazardous substances. Furthermore, aluminum sheets boast resilience against elevated temperatures and pressures, rendering them well-suited for an extensive array of chemical filtration applications.

- Q:Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated.

- Q:Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent as they have malleable properties that allow them to be easily shaped or formed into desired angles or curves.

- Q:What is the thickness of the aluminum sheets?

- The thickness of the aluminum sheets varies depending on the specific product or application.

- Q:Can aluminum sheets be used for electrical wiring?

- Electrical wiring cannot utilize aluminum sheets. Although aluminum boasts good conductivity, its high electrical resistance renders it unsuitable for such purposes. Copper, on the other hand, is the preferred material for electrical wiring due to its low resistance and superior efficiency in conducting electricity. Moreover, aluminum is susceptible to oxidation, which may result in inadequate conductivity and potential fire risks. Copper wires, on the contrary, are meticulously crafted and produced to comply with electrical safety standards, guaranteeing dependable and secure electrical connections.

- Q:Are the aluminum sheets suitable for electrical conductivity applications?

- Indeed, aluminum sheets prove to be a fitting option for electrical conductivity applications. Possessing a high level of conductivity, aluminum demonstrates an electrical conductivity that is approximately 61% of copper's. Consequently, it has become widely favored for a multitude of electrical and electronic applications that prioritize conductivity. Notably, aluminum sheets find purpose in the fabrication of power transmission lines, electrical cables, bus bars, and heat sinks, among other uses. Furthermore, aluminum boasts attributes such as lightweightness, resistance to corrosion, and commendable thermal conductivity, all of which contribute to its suitability for electrical conductivity applications.

- Q:hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- yes aluminum wire is susceptible to stress and braking but only if there is a stress bend or over twisting the wire. As long as you aren't stressing the wire ie: bending repeatedly where it's tacked down or over twisting the ends (which will break on copper as well) then you shouldn't have any problems. just be sure to support any heavy fixtures as the weight can stress the wire. I hope this helps

- Q:Are aluminum sheets suitable for use in electrical applications?

- Yes, aluminum sheets are suitable for use in electrical applications. Aluminum is an excellent conductor of electricity, and its high conductivity allows for efficient transmission of electrical current. Aluminum sheets are commonly used in electrical applications such as power transmission lines, electrical wiring, and electrical enclosures. Additionally, aluminum is lightweight, which makes it easier to handle and install. It is also resistant to corrosion, which ensures long-term durability and reliability in electrical systems. However, it is important to note that aluminum has a lower conductivity compared to copper, so it may require larger gauge sizes to compensate for this difference. Overall, aluminum sheets are a viable and cost-effective option for various electrical applications.

- Q:Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent heat dissipation properties, making it suitable for protecting electronic components. Additionally, aluminum sheets can be easily fabricated to create custom enclosures that provide electromagnetic shielding and protection against environmental factors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

5083 Aluminium Coil And Foil Strip Household Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords