2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

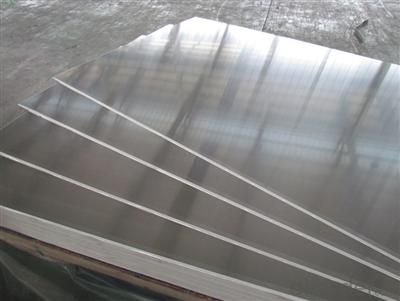

Aluminum sheet specifications:

1) Alloy : 1A99,2A12,2024,2219,2618,2A50,2A70,5A06,5083,6082,7075,7050, 7A85,7020 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 350mm

4) Width:20mm to 3300mm

5)Length: Accord to customer's requirements.

Reliable Quality,Reasonable Price and Good Service.

Any email will be replied with 24 hours. Thanks for your time!

6061 Aluminum plate/ aluminum thin sheet/ aluminum coil/ aluminum pipe application

The main alloy elements of 6061 alloy are Mg and Si and they form into Mg2Si. If it contains a certain amount of Mn and Cr, the bad effect of the iron can be neutralized. Sometimes you could also add a small amount of Cu and Zn to improve the strength of the alloy without decreasing its corrosion resistance obviously. Conductive material also contains a small amount of Cu which helps to counteract the bad effect of Ti and Fe on the electrical conductivity. In order to improve its cutting property, you could also add Pb and Bi. The alloy will has artificial aging hardening function when Mg2Si Solid soluble in aluminum.

6061-T651 is the main alloy elements of 6061 alloy. It is high quality aluminum products which are produced by heat treatment of pretensioning technique. Although its intensity cannot compare with 2XXX and 7XXX series, it has more magnesium and silicon alloy properties. It also has excellent process ability, good welding characteristics and plating properties, good corrosion resistance and high toughness. When you process it, there will be no deformation exist and no defects occur because of its dense material. What’s more, it is easy being polished and coloring the film and it has very good oxidation effect.

Representative applications include aerospace fixing device, electric appliance fixing device, communication field, automatic machinery parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder vehicles and so on.

Packaging & Delivery

| Packaging Details: | Bulk packaging for 6061 aluminum of do as you required |

| Delivery Detail: | 30 days for 6061 aluminum after you confirm the order |

- Q:or aluminum ? and what other gases are released?

- Aluminium does not normally react with water because of a surface coating of the highly unreactive Al2O3 that forms on exposure to atmospheric oxygen. In the presence of strong base, however, this compound dissolves due to complexation by hydroxide, similarly to how silver chloride dissolves in ammonia. Al2O3(s) + 2OH-(aq) + 3H2O(l) ----- 2[Al(OH)4]-(aq) Once this has occured, aluminium metal, a very strong reducing agent, is exposed to water. 2Al(s) + 6H+(aq) ----- 2Al3+(aq) + 3H2(g) Even though the solution is alkaline, there is still a low concentration of H+ formed by the autoprotolytic dissociation of water. The Al3+ formed then reacts with hydroxide to produce more [Al(OH)4]-. Yes, the hydrogen gas is from the water.

- Q:What is the weight of aluminum sheets?

- The weight of aluminum sheets can vary depending on the thickness and dimensions of the sheet. As a general guideline, the weight of aluminum sheets can range from about 2.7 grams per square centimeter (g/cm^2) for thin sheets to around 6.9 g/cm^2 for thicker sheets. However, it is important to note that these values are approximate and can vary slightly depending on the specific alloy and manufacturing process used. Therefore, it is recommended to consult the manufacturer or supplier for precise weight specifications for a particular aluminum sheet.

- Q:How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- They don't make aluminum siding anymore, thank god, they only make vinyl siding. It really depends on the brand you buy and the company that installs it. I used to be a tin man before becoming a professor and I can tell you that you should do a little research first. You want stuff that will hold up in wind, is easy to clean, has a nice look and colors won't fade. You want to be sure it is made of virgin vinyl, sounds weird but trust me, if it isn't it'll fade in a few years and look like crap. The company needs to know what they are doing too or the seams and lines will be terrible, so make sure your company is really in the siding business and not just some jack-leg contractor that says I can do it. You will end up with a crap job. Now I can't remember for certain and it has been a number of years, but 10 to 12 sounds good. I hope they are going to remove the old stuff, check your wood underneath and possibly put on a moisture barrier. I would ask what they plan on doing in detail. Good luck.

- Q:What are the maximum dimensions available for aluminum sheets?

- The available dimensions for aluminum sheets depend on a variety of factors, including the manufacturing process, supplier capabilities, and customer requirements. However, standard sizes for aluminum sheets typically range from 0.02 inches (0.5 mm) to 0.25 inches (6.35 mm) in thickness. The widths can vary from 24 inches (609.6 mm) to 72 inches (1828.8 mm), while the length can generally extend up to 144 inches (3657.6 mm). It is worth noting that these dimensions may differ depending on the specific supplier or manufacturer, and customized sizes can be produced to meet individual needs.

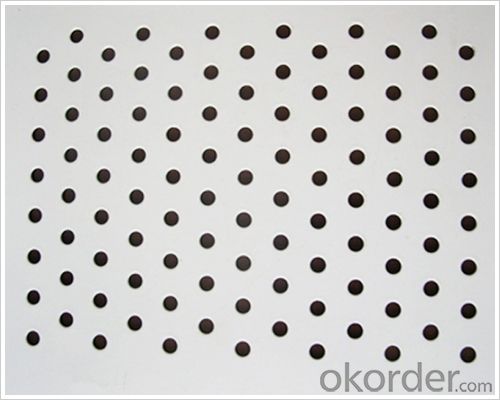

- Q:What are the different types of aluminum sheets available?

- There are several different types of aluminum sheets available, including plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, and painted aluminum sheets. Each type has its own unique attributes and applications.

- Q:What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q:What are the different surface treatments available for aluminum sheet?

- There are several surface treatments available for aluminum sheet, including anodizing, powder coating, painting, and polishing. Anodizing provides a durable and corrosion-resistant finish, while powder coating offers a wide range of colors and enhanced durability. Painting allows for customization with various finishes and colors, while polishing provides a shiny and reflective surface. Each treatment option offers different aesthetic and functional benefits, depending on the specific requirements and desired outcome.

- Q:Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q:What are the different methods of surface printing aluminum sheets?

- Some of the different methods of surface printing aluminum sheets include screen printing, offset printing, digital printing, and engraving.

- Q:Can aluminum sheets be anodized for added durability?

- Indeed, it is possible to anodize aluminum sheets in order to enhance their durability. Anodization involves an electrochemical procedure that generates a protective oxide layer on the aluminum surface. This layer not only improves the material's appearance, but also boosts its ability to resist corrosion, wear, and scratches. By undergoing anodization, aluminum sheets acquire a robust, long-lasting finish, rendering them highly suitable for a range of applications that necessitate durability, including construction, automotive, aerospace, and electronics industries. Moreover, anodized aluminum sheets can be dyed in various colors, enabling them to exhibit enhanced aesthetic appeal while retaining their durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords