1000 3000 5000 Series Cast Rolled Hot Rolled Mill Finish Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product details

| Product Name | Mill finish aluminum sheet |

| Alloy | 1050,1060,1100,3003,3004,3005,3105,5005,5052,5754,5083 |

| Temper | O, H12,H14,H16,H18,H22, H24,H32,H112 |

| Thickness | 0.18mm-350mm |

| Width | 300mm-1930mm |

| Inner packing | PVC film(30 μm, 60 μm, 80 μm) or Paper inter leaved |

| Outside packing | International wood pallet(fumigated) with steel strip |

b.Mechanical property

| Alloy grade | Bend | Tensile Strength( Mpa) | Elongation (%) |

| 1100 H14 | 1/2 closed | 132 | 13 |

c.Chemical composition

| Alloy grade | Si (%) | Fe(%) | Cu(%) | Mg (%) | Cr (%) | Mn (%) | Zn (%) | Ti (%) | Al (%) | Standard |

| 1100 H14 | 0.102 | 0.501 | 0.069 | <0.03< span=""> | <0.005< span=""> | <0.03< span=""> | <0.03< span=""> | 0.0191 | else | GB/T3880-2006 |

l Packaging & Delivery

Packaging detail: wooden cases that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

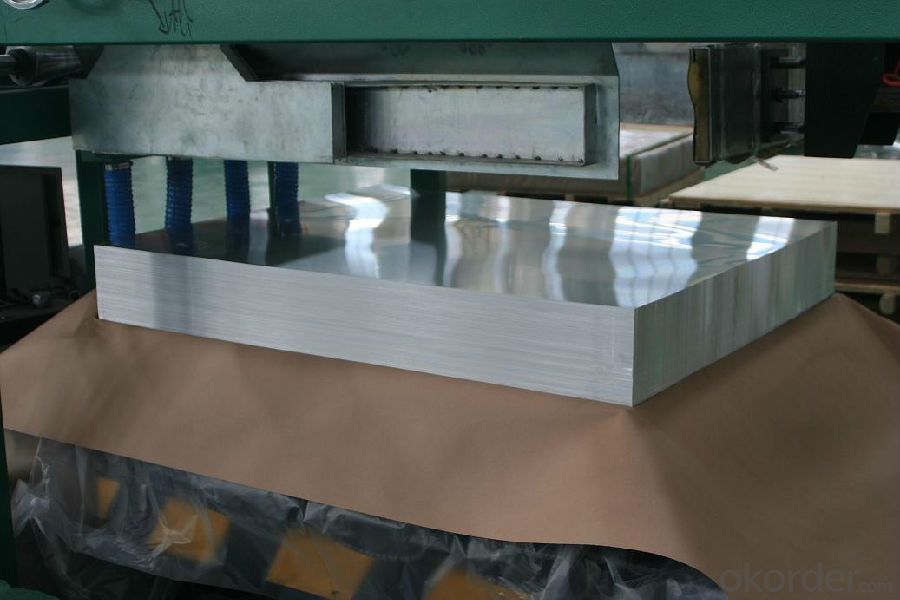

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Name: Amanda Qian

Email: amandaqian@okorder.com

- Q:What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot can vary depending on the thickness or gauge of the sheet. On average, a 1/8 inch thick aluminum sheet weighs around 1.9 pounds per square foot. However, thinner sheets may weigh less, while thicker sheets can weigh more. It is important to consider the specific thickness of the aluminum sheet when determining its weight per square foot.

- Q:What are the different grades or alloys of aluminum available for sheets?

- Aluminum sheets come in various grades and alloys, each with its own unique properties. Grade 3003, for example, is widely used and offers good corrosion resistance and moderate strength. It finds applications in general sheet metal work, cooking utensils, signage, and chemical equipment. On the other hand, grade 5052 is known for its excellent corrosion resistance and high strength. It is often utilized in marine applications like boat hulls and components, as well as aircraft parts and transportation equipment. Grade 6061 is a versatile aluminum grade that combines strength, weldability, and machinability. It is commonly chosen for structural components such as frames, railings, and automotive parts. It is also frequently employed in the architectural field for construction purposes. Apart from these grades, there are numerous specialized aluminum alloys available for specific applications. These alloys may possess enhanced characteristics like improved strength, heat resistance, or electrical conductivity. Examples of such alloys include 2024, 7075, and 6063. When choosing the appropriate aluminum sheet grade or alloy, it is crucial to consider factors such as desired strength, corrosion resistance, formability, and specific application requirements. Seeking advice from a knowledgeable supplier or expert can ensure the correct grade of aluminum is selected for the intended usage.

- Q:The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- If i was once you, i might depart a small 1cm gap on the high and cover it with mesh - these round ones don't appear to allow a lot air flow in any respect in my viv and i have three... I have a tendency to simply leave the glass open a bit of at both aspect. You'll have got to use a great mesh although to stop bugs escaping via it. BTW - i think you will have to make it slightly deeper... 1.5 at least in case you are maintaining reps a good way to grow to 12inch plus.

- Q:im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- Aluminum is a good choice if you plan on using it to grind more than just coffee. Plastic tends to soak up flavors due to oils in coffee, herbs and spices. So if you plan on multitasking metal is the way to go.

- Q:1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q:How does the thickness of aluminum sheet affect its formability?

- The thickness of an aluminum sheet has a significant impact on its formability. Generally, thinner sheets of aluminum are more malleable and easier to shape compared to thicker sheets. This is because thinner sheets have lower resistance to deformation and require less force to bend or stretch. Thicker aluminum sheets, on the other hand, have higher resistance to deformation and are less malleable. They require more force and energy to shape, and may be more prone to cracking or tearing during forming processes. Thicker sheets also have a higher likelihood of experiencing springback, where the material partially returns to its original shape after being formed. The formability of aluminum sheets is also influenced by the alloy composition and the specific forming process being used. In some cases, certain alloy compositions or heat treatments can enhance the formability of thicker sheets, making them easier to shape. In summary, the thickness of an aluminum sheet directly affects its formability. Thinner sheets are generally more malleable and easier to shape, while thicker sheets require more force and are less malleable. The alloy composition and specific forming processes being used can also impact the formability of aluminum sheets.

- Q:What is the color range available for aluminum sheets?

- The color range available for aluminum sheets is quite diverse and extensive. Aluminum sheets can be found in a variety of standard colors, including but not limited to silver, black, white, bronze, and gold. Additionally, aluminum sheets can be coated with various finishes, such as anodized, painted, or powder coated, which can further expand the color options. These coatings can provide a wide range of colors, including vibrant shades like red, blue, green, yellow, and more. Furthermore, custom colors can also be achieved through specialized processes, allowing for personalized and unique color choices. Overall, the color range available for aluminum sheets is extensive and flexible, catering to various aesthetic preferences and design requirements.

- Q:Are the aluminum sheets suitable for manufacturing power distribution panels?

- Absolutely, power distribution panels can be manufactured using aluminum sheets. Aluminum is an exceptional material choice for various industrial applications, including power distribution panels, due to its lightweight, durability, and resistance to corrosion. Not only can aluminum sheets effectively handle high electrical currents, but they also efficiently dissipate heat, ensuring a safe and efficient power distribution system. Furthermore, aluminum is widely accessible and cost-effective in comparison to alternatives like copper. Consequently, aluminum sheets are an excellent option for manufacturing power distribution panels.

- Q:Are aluminum sheets suitable for chemical storage containers?

- No, aluminum sheets are generally not suitable for chemical storage containers as aluminum is highly reactive and can corrode or react with certain chemicals, leading to potential leaks or contamination.

- Q:Can the aluminum sheets be used for manufacturing automotive radiators?

- Yes, aluminum sheets can be used for manufacturing automotive radiators. Aluminum is preferred in radiator manufacturing due to its excellent heat transfer properties, lightweight nature, and corrosion resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1000 3000 5000 Series Cast Rolled Hot Rolled Mill Finish Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords