Underground Epoxy Coated Composite Steel Pipe for Mining Steel-Plastic Pipeline Systems

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Epoxy Coated Composite Steel Pipe for Mining

Press grade: Applied for pipe system not bigger than 10MPa

Size: DN50MM-DN1600MM

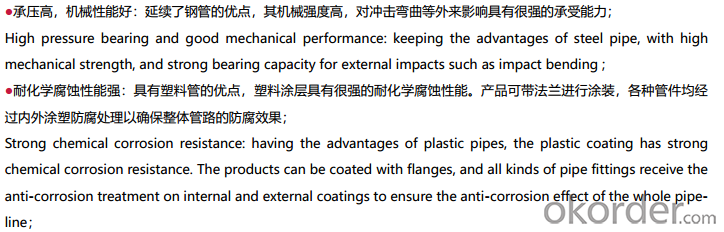

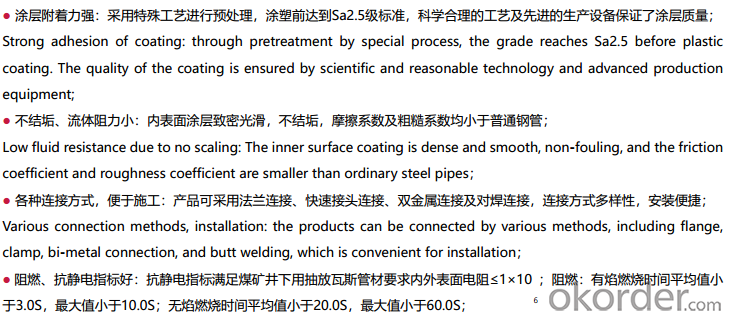

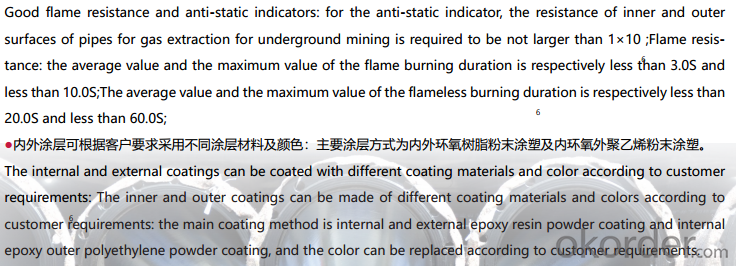

Features:

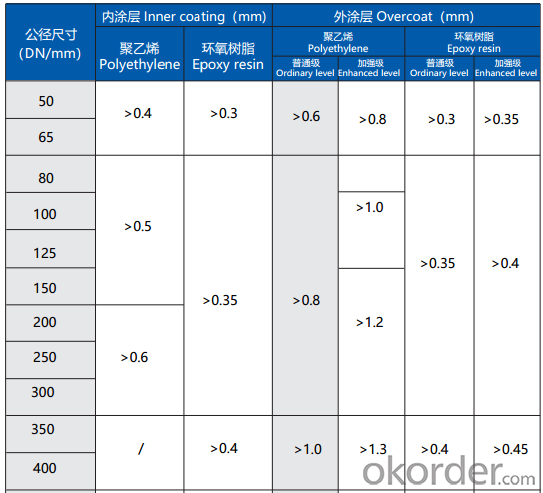

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:How to identify stainless steel pipe and steel pipe?

- Steel pipe according to the production method can be divided into two categories: seamless steel pipe and pipe joints, pipe joints as welded steel pipe.1. seamless steel tube according to the production methods can be divided into: hot-rolled seamless pipe, cold drawn tube, precision steel tube, heat expansion tube, cold spinning tube and extrusion tube.Seamless steel tubes are made of high quality carbon or alloy steel. They are hot-rolled and cold-rolled (drawn).Bundled steel pipe2. welded steel pipe for different welding process and divided into the furnace pipe welding (ERW) pipe and automatic arc welding, because of the different forms of welding seam welded pipe and spiral welded pipe is divided into two kinds, end its shape is divided into circular welded and shaped (square, flat) pipe.

- Q:What is the typical diameter range for steel pipes?

- The typical diameter range for steel pipes varies, but it typically falls between 1/2 inch to 48 inches.

- Q:How are steel pipes used in the oil and gas pipeline transportation?

- Steel pipes are used in oil and gas pipeline transportation due to their durability, strength, and resistance to corrosion. They are used to transport crude oil, natural gas, and other petroleum products over long distances. Steel pipes ensure the safe and efficient transfer of these resources from production sites to refineries and distribution centers, ensuring a reliable supply of energy for industries and consumers.

- Q:What is the importance of corrosion resistance in steel pipes?

- The importance of corrosion resistance in steel pipes is crucial as it helps to extend the lifespan of the pipes and maintain their structural integrity. Corrosion can weaken the pipes, leading to leaks, breakages, and ultimately, costly repairs or replacements. By preventing or minimizing corrosion, steel pipes can effectively transport fluids or gases, ensuring safety, efficiency, and longevity in various industries such as oil and gas, water supply, and construction.

- Q:What are the different methods of inspecting steel pipes for defects?

- There are several methods for inspecting steel pipes for defects, including visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing.

- Q:What are the quality control measures for steel pipe production?

- Quality control measures for steel pipe production typically involve several steps to ensure the final product meets the required specifications and industry standards. These measures may include inspection of raw materials, such as the steel coils or plates, to ensure they meet the required chemical composition and mechanical properties. During manufacturing, various processes like forming, welding, and heat treatment are closely monitored to maintain dimensional accuracy and integrity. Non-destructive testing methods, such as ultrasonic or radiographic inspection, are often employed to detect any defects or anomalies in the pipes. Additionally, visual inspection, surface treatment assessment, and mechanical testing are conducted to assess the overall quality before the pipes are released for distribution.

- Q:How are steel pipes connected or joined together?

- Steel pipes are typically connected or joined together using various methods such as welding, threading, flanges, or couplings.

- Q:How do you calculate the pipe deflection for steel pipes?

- To calculate the pipe deflection for steel pipes, you need to consider several factors. The deflection of a pipe is the bending or displacement that occurs when a load is applied to it. Here are the steps to calculate the pipe deflection: 1. Determine the properties of the steel pipe: You need to know the material properties of the steel pipe, including its Young's modulus (E) and its moment of inertia (I). Young's modulus represents the stiffness of the material, while the moment of inertia measures its resistance to bending. 2. Identify the load applied: Determine the type and magnitude of the load that will be applied to the pipe. This could include factors such as internal pressure, external loads, or thermal expansion. 3. Use the appropriate formula: Depending on the type of load and the support conditions of the pipe, you will need to use the appropriate formula to calculate the deflection. For example, if the pipe is simply supported (fixed at both ends), you can use the formula δ = (5 * w * L^4) / (384 * E * I), where δ represents the deflection, w is the load per unit length, L is the length of the pipe, and E and I are the material properties mentioned earlier. 4. Input the values and calculate: Plug in the values of the load, pipe length, and material properties into the formula. By doing so, you can calculate the deflection of the steel pipe. It is important to note that the calculation of pipe deflection is a complex process that requires expertise in structural engineering. Therefore, it is advisable to consult a professional engineer or use specialized software for accurate and reliable results.

- Q:How are steel pipes used in the manufacturing of machinery?

- Steel pipes are used in the manufacturing of machinery primarily for conveying fluid or gas, providing structural support, and acting as a conduit for electrical wiring. They are commonly used as the framework for various machine components, such as conveyor systems, hydraulic equipment, and pneumatic systems. Steel pipes offer durability, strength, and versatility, making them an essential material in machinery manufacturing.

- Q:Can steel pipes be used for transporting liquids and gases?

- Yes, steel pipes can be used for transporting both liquids and gases. Steel pipes are known for their durability, strength, and resistance to corrosion, making them suitable for a wide range of applications, including the transportation of fluids and gases. They are commonly used in industries such as oil and gas, water supply, sewage systems, and chemical processing plants. Steel pipes provide a reliable and efficient means of conveying liquids and gases over long distances, ensuring the safe and efficient transportation of these substances.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Underground Epoxy Coated Composite Steel Pipe for Mining Steel-Plastic Pipeline Systems

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords