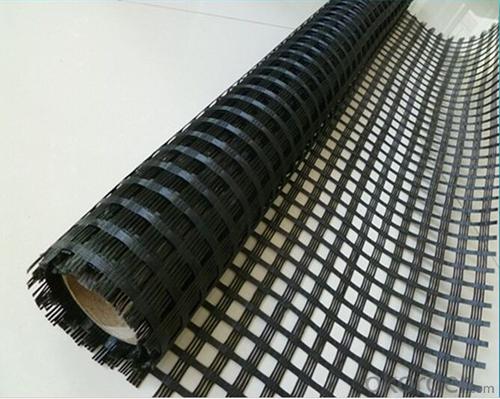

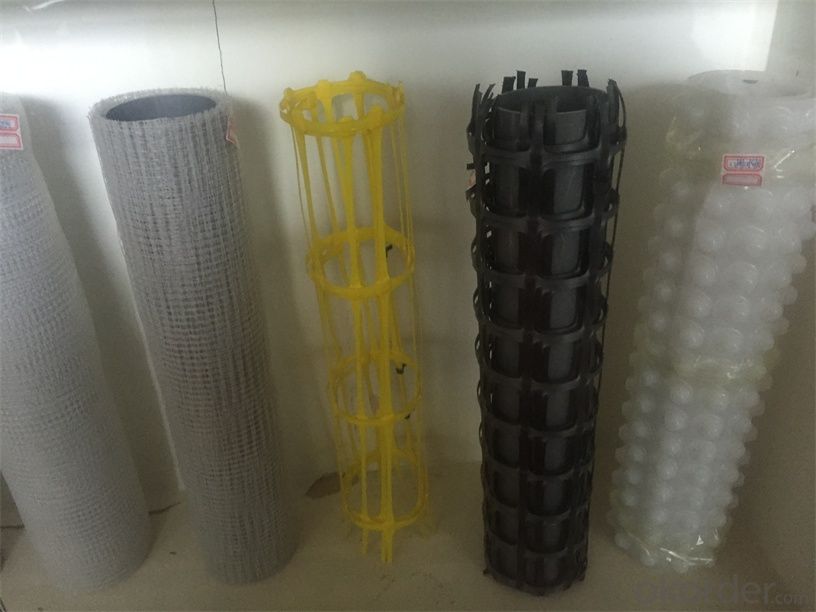

PVC Coated Polyester Geogrid Warp knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Type: | Geogrids | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CMAX

|

Model Number: | polyester geogrid | Material: | Polyester | note: | plastic geogrid |

tensile strength: | 15,20,25,30,40,50,60,70,80,90,100,110,120 and so on | mesh size: | 36mm*36mm | roll size: | 3.95*100m or 3.95*50m |

certificate: | CE ISO |

Packaging & Delivery

Packaging Details: | plastic geogrid packing in roll or customized |

Delivery Detail: | 5 days |

Reinforcement Polyester Geogrid :

(Warp Knitted Polyester Geogrid) :

Size | PET30/30--PET400/400; PET40/30--PET600/30 |

Price:FOB QINGDAO PORT | USD 0.3/Sq.m -- 5.0/Sq.m (LARGER QUANTITY WITH NICE PRICE) |

Packing in Roll

|

Roll width 3.95 Meter, 168 rolls in one 40HC Container.

|

Tensile strength at break | 30kn~600kn |

Stretching ratio | 13% |

Grid size | 12.7*12.7mm, 25.4*25.4mm, 50.8*50.8mm |

Mesh size | 9*9mm, 20*20mm, 35*35mm |

Roll width | 1.5m, 2m,3m,3.95m,5.8m |

Roll length | 50m, 100m |

Coating | PVC |

40HC container: | about 20000 Sq.m --50000 Sq.m |

Customize: | You can get more than what you pay for. Min 10000Sq.m |

Place of Origin | SHANDONG DAGENG, TAIAN CITY, SHANDONG, CHINA. |

Certificate | ISO ,CE |

FAQ

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C , Western Union,Paypal ...

3. What’s your delivery method ?

By sea , By train , etc

4. What's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable

- Q:What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing include: 1. Raw material testing: Ensuring that the materials used in the manufacturing process meet the required specifications and quality standards. 2. Process control: Implementing strict monitoring and control of each stage of the manufacturing process to ensure consistency and adherence to quality standards. 3. Product testing: Conducting rigorous testing of the geogrids at various stages of production to evaluate their mechanical properties, such as tensile strength, elongation, and durability. 4. Statistical process control: Using statistical methods to monitor and control the manufacturing process, identifying any deviations from the desired quality standards and taking appropriate corrective actions. 5. Quality inspections: Conducting regular inspections of the manufacturing facilities and equipment to ensure proper maintenance and calibration, preventing any potential quality issues. 6. Traceability: Implementing a system to track and trace each batch of geogrids manufactured, ensuring accountability and facilitating prompt recall or corrective actions if necessary. 7. Continuous improvement: Regularly reviewing and analyzing quality data, customer feedback, and industry trends to identify areas for improvement and implement corrective and preventive measures. By implementing these quality control measures, geogrid manufacturers can ensure consistent production of high-quality products that meet the required standards and customer expectations.

- Q:Are geogrids resistant to biodegradation?

- Yes, geogrids are typically resistant to biodegradation. Geogrids are made from synthetic materials such as polyester or polypropylene, which are designed to be durable and resistant to decay caused by biological organisms or environmental factors. This resistance to biodegradation makes geogrids suitable for long-term applications in civil engineering, soil stabilization, and erosion control.

- Q:What are the advantages of using geogrids in ground reinforcement?

- There are several advantages to using geogrids in ground reinforcement. Firstly, geogrids provide increased stability and load-bearing capacity to the soil, making them beneficial for areas with weak or unstable ground. Secondly, they help prevent soil erosion, as the geogrids act as a barrier that holds the soil in place. Additionally, geogrids can reduce construction costs by allowing for the use of locally available, less expensive fill materials. They also facilitate faster construction times, as they are easy to install and require minimal excavation. Overall, geogrids offer a cost-effective and efficient solution for ground reinforcement projects.

- Q:Are geogrids resistant to seismic forces?

- Yes, geogrids are designed to be resistant to seismic forces. They are made from durable materials that can withstand the dynamic forces generated during an earthquake, providing stability and reinforcement to soil and structures. Geogrids help distribute seismic forces and prevent soil liquefaction, making them a reliable solution in areas prone to earthquakes.

- Q:How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and structural support to the soil or sediment. They are commonly used to prevent erosion and maintain the integrity of coastal areas. The geogrids act as a barrier that holds the soil in place, effectively reducing the impact of wave action and water currents. This reinforcement enhances the stability of the shoreline and helps to prevent the loss of soil or sediment, ultimately protecting the coastline from erosion.

- Q:How do geogrids improve the performance of geogrid-reinforced earth walls?

- Geogrids improve the performance of geogrid-reinforced earth walls by providing tensile strength and stabilizing the soil, which helps to prevent the wall from sliding or collapsing. They distribute the forces exerted on the wall more evenly, reducing stress concentration and increasing overall stability. Additionally, geogrids enhance drainage and soil compaction, further enhancing the wall's performance.

- Q:Can geogrids be used in temporary construction haul roads?

- Yes, geogrids can be used in temporary construction haul roads. Geogrids are commonly used to reinforce road bases and improve their load-bearing capacity. They can effectively distribute the load and prevent the formation of ruts and potholes, making them suitable for temporary haul roads during construction projects.

- Q:Can geogrids be used in green roof applications?

- Yes, geogrids can be used in green roof applications. Geogrids provide reinforcement and stability to the green roof system, helping to prevent soil erosion and retain water. They can help distribute the load of the green roof evenly, ensuring structural integrity and longevity.

- Q:Can geogrids be used in soil erosion control for agriculture?

- Yes, geogrids can be used in soil erosion control for agriculture. Geogrids are commonly used to reinforce and stabilize soil, preventing erosion caused by water runoff or wind. They provide strength and stability to the soil, reducing the risk of erosion and preserving the integrity of agricultural land.

- Q:Glass fiber grating with large pulling force for Expressway

- The glass fiber geogrid is made of glass fiber alkali free roving as the main raw material, and the net structure material is made by certain knitting technology

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Polyester Geogrid Warp knitting

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords