Bitumen Coated Fiberglass Geogrid with High Tensile Strength for Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bitumen Coated Fiberglass Geogrid with High Tensile Strength(30KN*30KN-200KN*120KN) for Reinforcement

1. Production Introduction for Bitumen Coated Fiberglass Geogrid with High Tensile Strength(30KN*30KN-200KN*120KN) for Reinforcement

Fiberglass geogrid is a kind of plane network shape that selects excellent reinforcement non-alkali fiberglass yarn.

It is weaven into base material by using foreign advanced warp knitter and warp knitted directional structure. It make full use of yarn strength in textile, improve its chemical performance and make it have good tension resistance, tearing resistance and creep resistance and formed by excellent modified asphalt coating treatment. It follows similar and compatible principle, lays stress on its synthetic performance with asphalt mixture, protects glass fiber base material fully and improve wearing resistance and shearing force resistance of base material so as to make road surface reinforce , to prevent highway harm such as crack and rut form occurring and to solve the problem that asphalt road surface is difficult for reinforcement.

2. Production Property for Bitumen Coated Fiberglass Geogrid with High Tensile Strength(30KN*30KN-200KN*120KN) for Reinforcement

The product has high intensity ,low elongation ratio, thermostable, high module, light weight , good toughness, anti-corrosive, long life and so on characteristics, and can be applied in the old cement road surface ,runway service ,the dike ,the river bank, the side slope production ,project domains and so on road bridge connection surface enhancement processing , It can reinforce the road surface and prevents the road surface rut fatigue cracking the hot –cold expansion crack and following reflection crack , and can scatter the road surface bearing stress, extence road surface service life ,the high tensile strength and the low elongation ratio, no long-term slow change .The physical chemistry stability and hot –stability are good ,anti-weary dehiscence, anti-low temperature shrinkage crack and postpone reflection crack.

3. Production Specification for Bitumen Coated Fiberglass Geogrid with High Tensile Strength(30KN*30KN-200KN*120KN) for Reinforcement

Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | EGA150-150 | EGA200-200 | EGA300-300 | |

Mesh size(mm) | 25.4×25.4 Or 12.7×12.7 Or 50.8x50.8 | ||||||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 | 150 | 200 | 300 |

Across warp | 30 | 50 | 80 | 100 | 120 | 150 | 200 | 300 | |

Elongation at break ≤(%) | Warp direction | 4 | |||||||

Across warp | 4 | ||||||||

Elasticity modulus(GPA) | 67 | ||||||||

Thermal tolerance | -100~280°C | ||||||||

Width(m) | 1.0-6.0 | ||||||||

4. Production Application for Bitumen Coated Fiberglass Geogrid with High Tensile Strength(30KN*30KN-200KN*120KN) for Reinforcement

1). It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2). it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3). it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4). it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5). it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

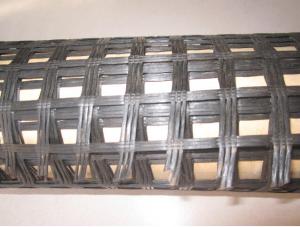

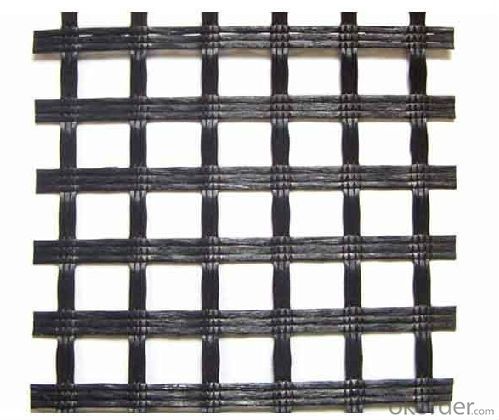

5. Production Photos for Bitumen Coated Fiberglass Geogrid with High Tensile Strength(30KN*30KN-200KN*120KN) for Reinforcement

6. RFQ

1) Wha's your payment terms?

T/T, L/C at sight

2) What's your delivery time?

Within 15days against prepayment received or original L/C.

3) What's your package?

Woven bag

- Q:Where the geogrid is the cheapest! Plastic fiber polyester fiberglass geogrid there?

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. 1) Plastic Geogrid

- Q:Geogrid what to do

- Longitudinal transverse tension

- Q:Are geogrids suitable for use in soil reinforcement for pipeline crossings?

- Yes, geogrids are suitable for use in soil reinforcement for pipeline crossings. They provide effective reinforcement by distributing loads and improving soil stability, reducing the risk of settlement or failure. Geogrids are designed to withstand high tensile forces and can enhance the performance and longevity of pipeline installations in various soil conditions.

- Q:Do geogrids require any maintenance?

- Yes, geogrids require minimal maintenance. Periodic inspections should be conducted to ensure they are functioning properly and not damaged. Any debris or sediment buildup should be removed, and any damaged geogrids should be repaired or replaced. Overall, regular maintenance is recommended to ensure the longevity and effectiveness of geogrids.

- Q:What are the factors that affect the performance of geogrids under cyclic loading?

- The factors that affect the performance of geogrids under cyclic loading include the type and quality of the geogrid material, the design and installation of the geogrid, the magnitude and frequency of the cyclic loading, the soil properties and conditions, and the duration of the cyclic loading.

- Q:Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are a type of geosynthetic material that provide additional support and stability to the surrounding soil, preventing the pipeline from experiencing excessive deformation or damage. They are commonly used in pipeline installation and rehabilitation projects to increase the overall strength and load-bearing capacity of the soil, ensuring the long-term stability and functionality of the underground pipelines.

- Q:Are geogrids suitable for use in high-traffic areas?

- Yes, geogrids are suitable for use in high-traffic areas. Geogrids are designed to provide reinforcement and stabilization to the soil, making them ideal for areas with heavy vehicular loads. They distribute the load more evenly, reducing rutting and extending the lifespan of the pavement or surface. Thus, geogrids can effectively handle the demands of high-traffic areas.

- Q:Are geogrids resistant to acid degradation?

- Yes, geogrids are generally resistant to acid degradation. They are commonly made from materials such as polypropylene or polyester which have excellent resistance to acidic environments. This resistance allows geogrids to maintain their structural integrity and performance even when exposed to acidic conditions.

- Q:How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing additional reinforcement and enhancing the overall stability of the slope. They help distribute the loads more evenly, reducing the potential for soil erosion and slope failures. Additionally, geogrids increase the shear strength of the clayey soil, preventing excessive deformation and ensuring long-term stability of the slope.

- Q:Glass fiber grating with large pulling force for Expressway

- To improve the overall use of polyester geogrid using high strength nylon fiber filament, warp knitting mesh fabric.

1. Manufacturer Overview |

|

|---|---|

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Bitumen Coated Fiberglass Geogrid with High Tensile Strength for Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords