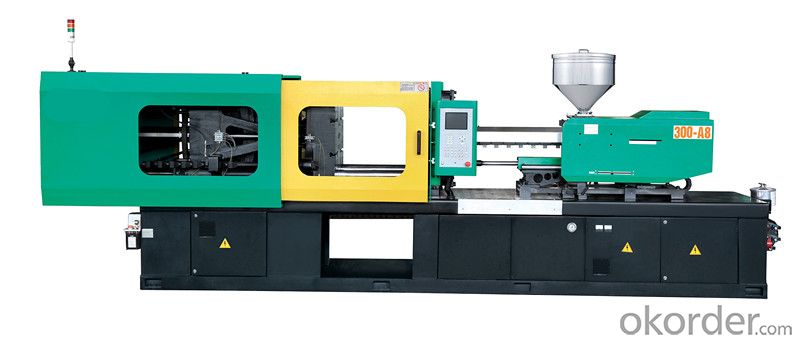

Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG300-A8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 673-980g

Clamping Force: 3000 kn

Opening Stroke: 570 mm

Power(W): 22kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Plastic Rubber Injection Moulding Machine

Warranty: One Year

Material: Stainless Steel

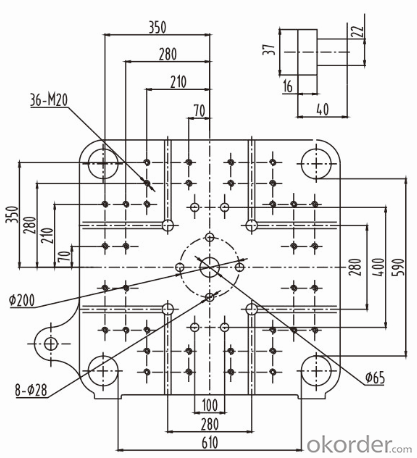

Space between Tie Bar: 610*590

Screw Diameter: 58-65-70 mm

Machine weight: 9.1T

Ejector stroke: 160mm

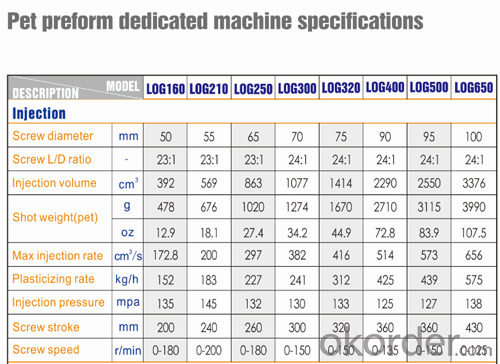

| Description | Unit | LOG-300A8 | ||

| international recognized models | 1400/300 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 740 | 929 | 1077 |

| Shot volume | g | 673 | 845 | 980 |

| Oz | 23.5 | 29.5 | 34.2 | |

| Screw diameter | mm | 58 | 65 | 70 |

| Injection diameter | mpa | 190 | 151 | 130 |

| Screw L:D ratio | 24:01:00 | 22:01 | 20:01 | |

| Scerw steoke | mm | 300 | ||

| Screw rotate speed | r/min | 0-150 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 3000 | ||

| Opening stroke | mm | 570 | ||

| Platen size | mm*mm | 870*850 | ||

| Space between tie bars | mm*mm | 610*590 | ||

| Maldthickness | mm | 200-600 | ||

| Platen Mix stroke | mm | 1170 | ||

| Ejection stroke | mm | 160 | ||

| Ejcetion force | kN | 77 | ||

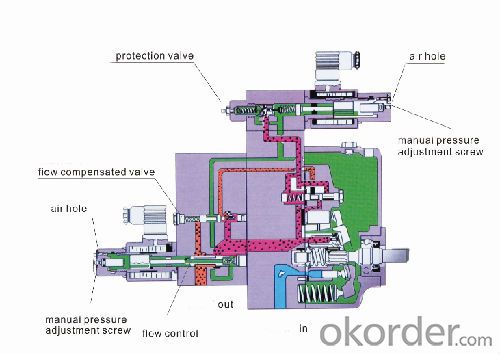

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 29 | ||

| Heating power | kw | 23.6 | ||

| Number of temp.conteol | 5+nozzle | |||

| Other | ||||

| Cycle time | sec | 5 | ||

| Tank volume | L | 380 | ||

| Machine dimesions | m*m*m | 6.4*1.6*2.18 | ||

| Weight of machine | kg | 11000 | ||

Packaging & Delivery

| Packaging Details: | Packaging Details: 20 GPcabinet Delivery Detail: In one week after get payment |

|---|

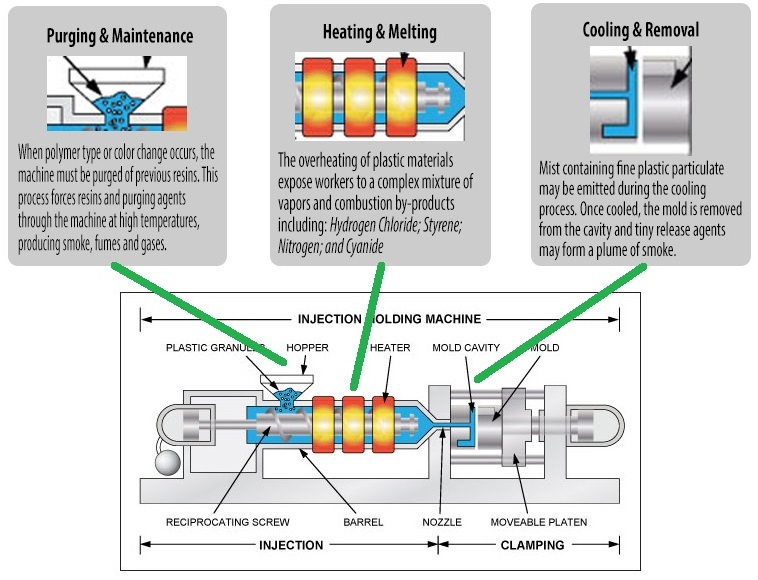

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

- Q:What are the famous brands of injection molding machines?

- The best is Germany, Abog (formerly known as Albemarle, but by others to register the ARBURG)Other brands in Germany: Baden, field, BATTENFELD, Demag, DEMAGAustria: ENGELJapanese brands: Toshiba TOSHIBA, Japan TOYO, MITSUBISHI MITSUBISHI, Sumitomo SEDU, FANUC FANUC, Niigata NIIGATA, Nippon Steel JSW, NISSEI NISSEI and UBE UbeAmerican brand: Cincinnati CINCINNATIDomestic or Hong Kong and Taiwan: Haitian, Zhen Xiong, Jia Ming, Donghua and so on

- Q:I want to know the injection speed of injection molding machine. What is the specific unit?

- But the percentage displayed on the computer control panel of the injection molding machine. The maximum speed (rating) of the machine instructions is 100% at this rate.

- Q:How to check the mold opening stroke of injection molding machine

- 1. the maximum opening stroke of injection molding machine has nothing to do with the die thicknessMainly refers to the clamping mechanism for injection molding machine with hydraulic machinery, such as XS-Z-30, XS-Z-60, XS-ZY-125, XS-ZY-350, XS-ZY-500, XS-ZY-1000 and G54-S200/400 type injection molding machine, the mold opening stroke by the connecting rod mechanism (or clamping cylinder) determines the maximum stroke, irrespective of the thickness of the mold.For injection mold with single parting surface:Smax = H1+H2 + mm (5 ~ 10)For injection mold with double parting surface:Smax = H1 +H2 + +a (5 ~ 10) mmType: Smax injection molding machine maximum mold opening stroke (mm);H1 plastic parts (mm, H1) launched a distance - like mold core is equal to the height, but for the plastic parts of the inner surface is stepped, sometimes do not have to launch the full height core can remove the plastic parts, then H1 can be determined according to specific circumstances, in order to successfully remove the plastic parts;H2 a piece of plastic height, including the height of the castable (mm) of the gating system that is connected to the plastic part.A the distance between the fixed die seat plate and the runner plate required by the casting system to remove the condensate (mm).

- Q:What brands of injection molding machines are there in Taiwan?

- Taiwan brand molding machine a lot of ah, there are at least dozens of brands, relatively well-known: Taichung, Taiwan Zhenxiong, quanlifa, fuqiangxin, Nan Rong, Hua Ronga and so on, what you want to buy a machine? What's the requirement of your product?

- Q:Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 1. are you fully automated? If it's fully automated, then you'll be able to record each exception from minutes to minutes, so you know your abnormal hours. If it is semi-automatic production, it depends on the boot staff, the door is not stable, this can be seen inside the injection molding machine.

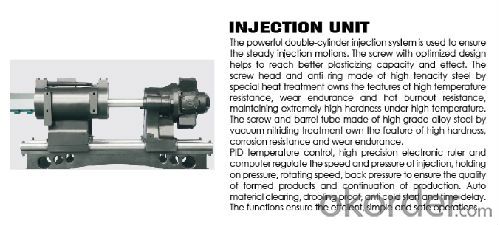

- Q:What is an injection molding machine?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment.Working principle:The working principle of injection molding machine and injection syringe with similar, it is the use of screw (or piston) thrust, the plasticizing good molten state (i.e. viscous flow) plastic injected into the mold cavity closed good after curing stereotypesmade the process of the products. Injection molding is a cycle process, each cycle mainly include: quantitative feeding - melt plasticization - pressure, injection - filling mold cooling - die opening pieces. Take out the plastic parts and then close the die for the next cycle.

- Q:How can the injection machine be set with parameters?

- This problem is too big, ha haSpecific analysis of specific issues

- Q:How to reset the EM-120 origin of the injection machine?

- 6, locking machine to machine hinge straight;7, repeat third steps;8, enter 1 at the default mode 1; move the cursor back to preset 1; appear as input Press confirm again;9, enter 2000 at the preset mode 2;10, repeat the lock die 3 to 4 times to the machine hinge straight, see the actual value of the lock more than how many; 2000 minus the remaining numberValue; enter preset 2;11, reset the high pressure die termination position and adjust the clamping force to the die.

- Q:I want to study and maintain the injection molding machine, but I don't know whether it's difficult or not. What are the main points I should pay attention to when I study?

- Put the book on a set up useful to you, as you said above, it is not a long time still can not find a reason, if you want to say, or to do a period of time, first understand the machinery, besides, school repair is not a day for two days to learn, only to do it will do. As for the main points is the classification to first distinguish fault, generally is the mechanical, electrical, hydraulic and other three categories, what process, just say not clear, if there are problems, done will be remembered

- Q:Haitian injection molding machine alarm, hydraulic insurance exception, what are the reasons?

- From what you have described, the problem is the hydraulic fluid, such as insufficient hydraulic fluid and impurities in the hydraulic fluid. Check, either add hydraulic oil, or replace the hydraulic oil.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-300A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords