FIBER REINFORCE PLASTIC Pultruded Cable Tray

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

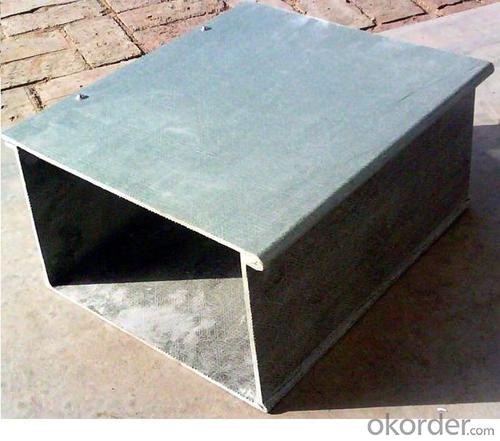

Brief Introduction of FRP Pultruded Cable Tray High Strength and Anti Corrosive

During the pultrusion process, the raw materials are pulled through a heated steel forming die using a continuous pulling device. FRP Pultruded Profile are made of different resins reinforced with fiberglass, by pultrusion technology.

Main Features of FRP Pultruded Cable Tray High Strength and Anti Corrosive

Corrosion resistant

High strength & light weight

Long service life

Fire retardant

Impact resistant

Nonconductive and thermal insulation

Non-magnetic electromagnetic transparency

Dimensional stability, Bright color

Low-maintenance

Main Specification of FRP Pultruded Cable Tray High Strength and Anti Corrosive

Physical Property:

Raw Materials: | · Reinforcement material: Fiberglass, glass mat, continuous strand mat, surfacing mat, needled mat. · Basis material: Unsaturated polyester resin, epoxy resin, vinylester resin |

Color: | Grey, Blue, Yellow, Red, other customized colors |

Density: | 1.5-2.0 g/cm3 |

FRP Cable Tray | Dimension/mm | Cross Section Area/cm2 | Weight Kg/m | ||

L | W | H | |||

001 | 100 | 50 | 3 | 6.32 | 1.169 |

002 | 100 | 100 | 4 | 12.18 | 2.253 |

003 | 150 | 100 | 4 | 14.18 | 2.581 |

004 | 150 | 150 | 5 | 22.50 | 4.163 |

005 | 200 | 100 | 4 | 16.18 | 2.993 |

006 | 200 | 150 | 5 | 25.00 | 4.625 |

007 | 200 | 200 | 6 | 35.78 | 6.619 |

008 | 300 | 100 | 4 | 20.18 | 3.733 |

009 | 300 | 150 | 5 | 30.00 | 5.550 |

010 | 300 | 200 | 6 | 41.78 | 7.729 |

011 | 400 | 100 | 4 | 24.18 | 4.473 |

012 | 400 | 150 | 5 | 35.00 | 6.475 |

013 | 400 | 200 | 6 | 47.78 | 8.839 |

014 | 500 | 100 | 4 | 28.18 | 5.213 |

015 | 500 | 150 | 5 | 40.00 | 7.400 |

016 | 500 | 200 | 6 | 53.78 | 9.949 |

017 | 600 | 100 | 4 | 32.18 | 5.953 |

018 | 600 | 150 | 5 | 45.00 | 8.825 |

019 | 600 | 200 | 6 | 59.78 | 11.059 |

020 | 800 | 100 | 4 | 40.18 | 7.433 |

021 | 800 | 150 | 5 | 55.00 | 10.175 |

022 | 800 | 200 | 6 | 71.78 | 13.279 |

Main Application of FRP Pultruded Cable Tray High Strength and Anti Corrosive

The pultruded FRP Cable Tray is suitable for electrical cable, controll-ing cable, lighting cable and distrib-uting line with the voltage under 10KV. It can be installed with technological line, suspended above the floor or under beam, and also can be installed on the inside or outside wall or the sidewall of tunnel and cable ditch.

Our other FRP composite products are pultrusion fiberglass square tube, frp channel, frp beams, frp round tube, frp flat bar, frp angle, frp cable tray, frp rod, frp rock bolt, frp rebar, frp mortar pipe and other frp profiles.

Contact us for more details.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q:Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP pultrusion profiles can be used in water treatment plants. FRP (Fiber-Reinforced Polymer) is a corrosion-resistant material that is well-suited for water treatment applications. It is lightweight, durable, and has excellent chemical resistance properties, making it ideal for use in environments with exposure to water and various chemicals. Additionally, FRP pultrusion profiles offer design flexibility and can be customized to meet specific project requirements.

- Q:How do FRP pultrusion profiles perform in coastal environments?

- FRP pultrusion profiles perform exceptionally well in coastal environments due to their inherent resistance to corrosion, moisture, and UV radiation. Thanks to their non-metallic composition, they are not susceptible to rust or degradation caused by saltwater exposure. Additionally, FRP profiles have high strength-to-weight ratios, making them ideal for applications in coastal areas where weight and durability are crucial.

- Q:Can FRP pultrusion profiles be used in the automotive industry?

- Certainly, the automotive industry can certainly make use of FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess several advantages that render them appropriate for automotive purposes. To begin with, FRP pultrusion profiles are lightweight, a critical factor in the automotive industry as it contributes to better fuel efficiency and reduced vehicle weight. Vehicles that are lighter consume less energy and emit fewer pollutants, making them more eco-friendly. Moreover, FRP pultrusion profiles exhibit a remarkable strength-to-weight ratio, enabling them to provide high strength and stiffness while remaining lightweight. This characteristic makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. In addition, FRP pultrusion profiles display exceptional corrosion resistance, a considerable advantage in automotive applications. Vehicles are frequently exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP ensures the durability and longevity of automotive components, even in challenging environments. Furthermore, FRP pultrusion profiles possess impressive impact resistance, a crucial aspect of automotive safety. They can effectively absorb and dissipate energy during impacts, reducing the risk of injury in the event of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be tailored to possess specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the combination of lightweight construction, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and extended component life, making them a viable alternative to traditional materials in automotive applications.

- Q:Can FRP pultrusion profiles be used in the renewable energy sector?

- FRP pultrusion profiles are definitely applicable in the renewable energy sector. They offer several advantages that make them suitable for various applications within the industry. One significant advantage of FRP pultrusion profiles is their exceptional strength-to-weight ratio. As large structures, like wind turbine blades or solar panel frames, are often involved in renewable energy projects, the lightweight nature of FRP profiles can significantly reduce transportation and installation costs. Additionally, their high strength ensures better load-bearing capabilities, guaranteeing the integrity and longevity of renewable energy infrastructure. Another benefit of FRP pultrusion profiles is their resistance to corrosion. Structures in the renewable energy sector are frequently exposed to harsh environments, such as offshore wind farms or coastal solar installations. The corrosion-resistant properties of FRP profiles make them an ideal choice as they do not rust or degrade when exposed to moisture, saltwater, or chemicals commonly found in these environments. This characteristic significantly reduces maintenance and replacement costs, making FRP profiles a cost-effective solution for the renewable energy sector. Moreover, FRP pultrusion profiles offer design flexibility. They can be custom-engineered to meet specific project requirements, allowing for the creation of complex shapes and sizes. This versatility enables the development of innovative and efficient renewable energy solutions, such as aerodynamically optimized wind turbine blades or lightweight support structures for solar panels. In conclusion, FRP pultrusion profiles are well-suited for the renewable energy sector due to their lightweight nature, high strength, resistance to corrosion, and design flexibility. These characteristics make them an excellent choice for various applications, including wind energy, solar power, hydroelectric projects, and more.

- Q:Are FRP pultrusion profiles resistant to caustic soda?

- FRP pultrusion profiles are generally immune to caustic soda, which is a potent alkaline substance capable of corroding certain materials. However, FRP pultrusion profiles consist of robust fibers (like fiberglass) combined with a resin matrix (such as polyester or epoxy). This composite construction renders them highly resistant to chemicals, including caustic soda. Consequently, FRP pultrusion profiles find extensive application in industries prone to exposure to corrosive substances, such as chemical processing, wastewater treatment, and mining. It is worth noting that the choice of resin in the FRP profiles, along with the concentration and temperature of the caustic soda, can impact the overall level of resistance.

- Q:Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q:Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Yes, FRP pultrusion profiles can be used in the construction of industrial flooring. These profiles are lightweight, durable, and corrosion-resistant, making them an ideal choice for industrial applications. They offer high strength-to-weight ratio, excellent load-bearing capacity, and resistance to chemicals, moisture, and extreme temperatures. Additionally, FRP pultrusions can be customized to meet specific design requirements, making them versatile for various industrial flooring applications.

- Q:How do FRP pultrusion profiles compare to steel or aluminum profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles offer several advantages over steel or aluminum profiles. Firstly, FRP profiles are extremely lightweight, making them easier to handle and install. This is particularly beneficial in industries where weight reduction is crucial, such as aerospace or automotive applications. Another significant advantage of FRP pultrusion profiles is their exceptional corrosion resistance. Unlike steel or aluminum, FRP does not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions. This property makes FRP profiles ideal for applications in marine environments or chemical processing plants, where traditional materials would quickly deteriorate. In terms of strength, FRP pultrusion profiles can match or even surpass steel or aluminum profiles. The unique combination of reinforcing fibers and polymer resin in FRP provides excellent tensile and flexural strength. Additionally, FRP profiles have a high stiffness-to-weight ratio, meaning they can withstand heavy loads while remaining lightweight. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties. Unlike metal profiles, FRP does not conduct electricity, making it a safe choice for electrical applications where insulation is crucial. While steel or aluminum profiles may have their own advantages in certain applications, FRP pultrusion profiles often provide a more cost-effective solution due to their long lifespan and low maintenance requirements. FRP profiles are not susceptible to rust, corrosion, or degradation, minimizing the need for frequent repairs or replacements. Overall, FRP pultrusion profiles offer a compelling alternative to steel or aluminum profiles, providing lightweight, corrosion-resistant, strong, and electrically insulating solutions for various industries and applications.

- Q:Can FRP pultrusion profiles be used in telecommunications towers?

- Telecommunications towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantageous features that render them suitable for this particular application. Firstly, FRP profiles possess a lightweight yet robust nature, facilitating effortless installation and reducing the overall structural weight of telecommunications towers. This characteristic is crucial as it aids in minimizing the burden imposed on the tower structure. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion, making them ideally suited for outdoor applications such as telecommunications towers that are constantly exposed to diverse environmental conditions. Unlike conventional materials like steel or wood, FRP profiles do not succumb to rust, rot, or deterioration when subjected to moisture, UV radiation, or chemicals typically encountered in outdoor environments. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, a critical aspect for telecommunications towers. These profiles are non-conductive, thereby reducing the likelihood of electrical interference or short circuits that might disrupt the tower's communication systems. Moreover, FRP pultrusion profiles can be produced in various shapes and sizes, thereby enabling customization and meeting the specific design requirements of telecommunications towers. This versatility facilitates seamless integration and compatibility with other components of the tower. Overall, the combination of lightweight composition, high strength, corrosion resistance, electrical insulation, and customization options renders FRP pultrusion profiles an advantageous and viable selection for utilization in telecommunications towers.

- Q:Can FRP pultrusion profiles be used in cooling towers?

- Yes, FRP pultrusion profiles can indeed be used in cooling towers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent corrosion resistance, lightweight construction, and high strength, making them ideal for cooling tower applications. These profiles can withstand the harsh environmental conditions typically found in cooling towers, such as exposure to chemicals, moisture, and temperature variations. Additionally, FRP pultrusion profiles are easy to install, require minimal maintenance, and have a long service life, making them a cost-effective choice for cooling tower construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBER REINFORCE PLASTIC Pultruded Cable Tray

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords