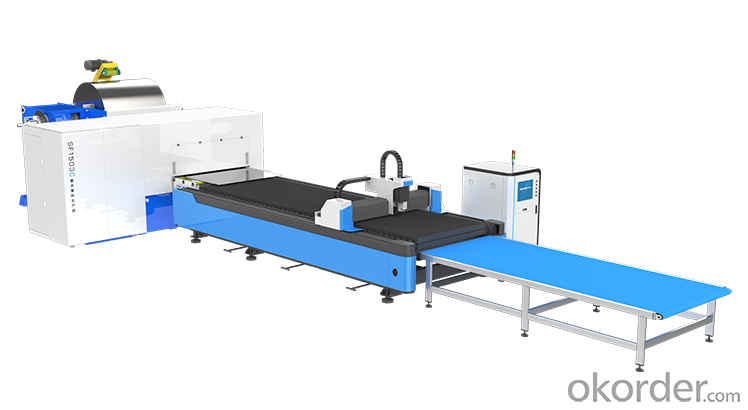

Automatic Metal Coil Decoiling Levelling and Blanking Fiber Laser Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Fiber laser blanking system combines a fiber laser cutting machine with an automatic metal coil feeding system resulting in an efficient coil fed laser cutting solution .

Laser blanking reduces power consumption compared to its alternatives, such as press lines and results more efficient and flexible.

The automatic design of the whole process, which is from loading-uncoiling-leveling-cutting saves labor, realizes the net cutting of coil materials, and improves the utilization of sheet materials.

Parameters

Model | Coil-fed Laser Blanking System |

Applicable materials | Cold rolled coil, galvanized coil, stainless steel coil, aluminum coil |

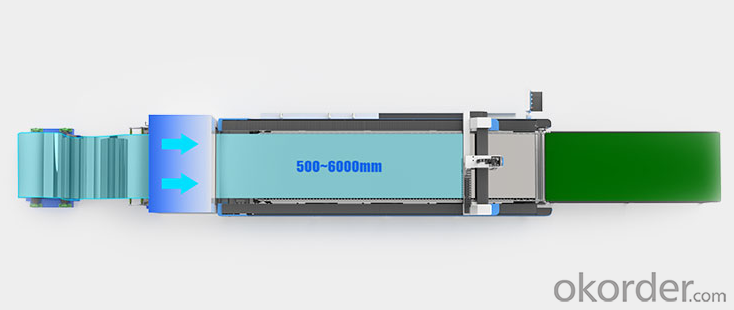

Working area(mm) | 3000*1500/4000*2000/6000*1500(mm) |

Laser power | 1kw/1.5kw/2kw/3kw/4kw |

Material thickness | 0.5-2mm |

Material width | 600-1500mm |

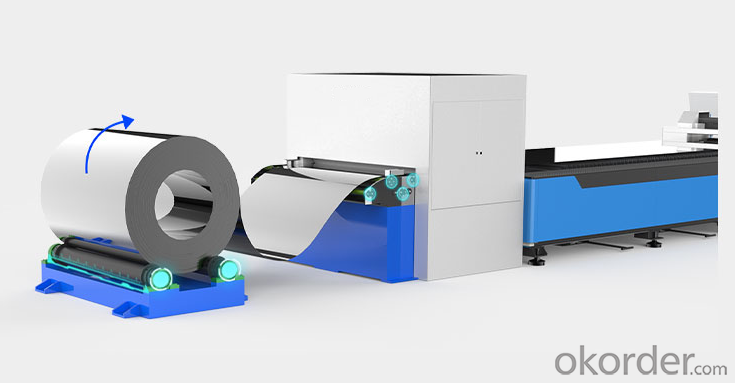

Maximum coil weight | 10T |

Maximum outer diameter of material | Φ1500mm |

Material inner diameter | Φ508/Φ610mm |

Feeding accuracy | ±0.5mm (calculated by 1000mm) |

CNC system | Feeding speed |

Details:

High work efficiency and cost saving

The load-bearing capacity of the single-support uncoiler is 10 T, and the feeding speed of uncoiler is 0-10m /min (stepless speed regulation).

Leveling sheet metal, eliminating the stress

After the coil is uncoiled, the plate is leveled by the leveling machine, and the stress of the plate during the leveling process is eliminated, so that the plate is smoother and a better cutting experience is obtained.

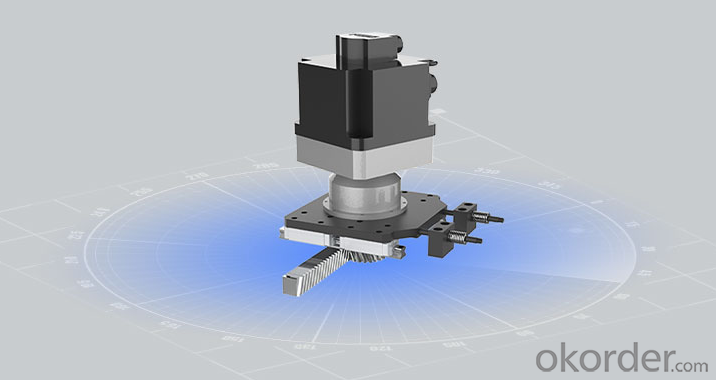

High precision positioning and rectifying process

The special screw nut is used to drive the rectifying roller to install the slide block, so as to realize the positive orientation of the plate , no need laser edging and save the cutting time of the plate.

High precision transmission structure

Ultra-precision transmission system is adopted, high transmission accuracy.

- Q:What is the main technology of Zhongshan flying dragon Hardware Technology Co., Ltd.?

- d sales of hardware, plastic products, electronic accessories, laser equipment; goods

- Q:4000W fiber laser cutting machine how much money

- go to the factory to check and see the effect. Laser cutting machine precision is all about, but cut out of the accuracy of the product is another matter, for security reasons, do not look at the text data of the major manufacturers, best to take the plates to each other there to make a kind of precision can meet requirements, see.

- Q:What are the main industries for laser equipment?

- China lidar market forecast and investment strategy planning analysis report in 2015-2020

- Q:How long is the life of the laser equipment?

- As for heating ceramics and bushings, there are several more than 100 thousand pages without replacing, so the quality is good

- Q:You score (200)!! Is it appropriate to buy a color laser printer or a color copier? A3, give me some advice

- The design of high voltage barrier network with point discharge is adopted to reduce the discharge of harmful gases such as ozone, and to reduce the damage to human body. R

- Q:How much is the cheapest equipment for the Eurostar fotona in Germany?

- The company is located in Germany de Tsune, production bases located in Slovenia, Denmark and Germany and other EU countries.

- Q:1500W laser cutting machine how much money?

- but also according to the machine configuration, the brand can set the price.

- Q:Development prospect of laser processing

- . According to the China Optical Association, the laser processing industry in China has developed rapidly, and the total output value has increased from 160 million yuan in 1999 to 1 billion 200 million yuan in 2003.

- Q:Which is good for laser equipment in China? Please introduce experts

- because there is no national investment funds will be a little expensive, in the customer service service in two service outlets throughout the country are very perfect,

- Q:Just interviewed two sales jobs. One is to do in Shenzhen Huaqiang North electronic components sales, one is Shenzhen laser equipment sales

- If the laser equipment is basically a one-time sale, but there is no consumables, up to one or two years after the change of parts, and the risk is very big, because the clerk received orders have to bear the risk for this order, if it is in a strong company, to be considered, because the laser equipment is

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Metal Coil Decoiling Levelling and Blanking Fiber Laser Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords