Hollow Core Particle Board for Decoration and Furniture Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m³

- Supply Capability:

- 40000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction: Hollow chipboard is usually used as core of Doors,and it is featured as light in weight , sound-proof anti-impact , temperature-keeping and stable in dimensions,The product reserves the virtues of wood and gets rid of its weak points such as skrinking after being wet ,and being heavy in weight,It is indeed an ideal green enwironment-friendly replacement to solid wood cores.

Pictures:

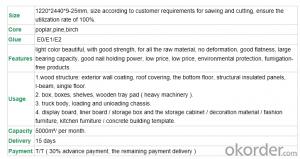

Description:

1)size:2000*125mm,2090*1180mm,2000*900mm

2)Thickness:24mm-38mm

3)Core:pine

4)Glue:E1

5)Density:350-400 kg/m³

Hollow chipboard Feafures and Advantages:

1)Envuronmental protection

2)Heat preservation

3)Sound insulation

4)Light in weight

5)Anti-impact

6)Stable in dimensions

7)Easy to processing

FAQ:

A: What's the main material of hollow chipboard?

B: Poplar

- Q:Particleboard industry is currently looking ahead

- so the effective utilization of forest resources and papermaking pulp waste has been paid more and more attention

- Q:Particleboard by product classification

- According to the arrangement of shavings in the slab, there are two kinds of directional and random type

- Q:So for the particleboard formaldehyde release of the situation how to deal with it?

- in fact, after the decoration of the room, such as Chlorophytum, Citrus grandis,

- Q:Particleboard production process requires proper hot pressing pressure

- and then sawing sanding, inspection packaging. But after the pressure can not heat stacked, otherwise it will increase the sheet brittle.

- Q:According to the surface conditions:

- According to the slab structure of single layer, three (including multi-layer), gradient three kinds of structure.

- Q:Current Prospects for Particleboard Industry

- and may be through the multi-species multi-functional finishes prefabricated specialization, forming an independent new industrial category

- Q:What is the modeling technology department?

- Hot-forming method mainly produces furniture accessories, interior decoration accessories and pallets and other products,

- Q:The Particleboard quality identification editor

- the general situation is fine fine, but at some point, such as sticky fire board, too fine to bad Hanging glue.

- Q:Market foreground and Industry development

- the quality of China's particleboard has been significantly improved, and re-accepted by the market,

- Q:What is the production process of particleboard

- The core moisture content should be appropriately lower than the surface layer to maintain proper flat tensile strength.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hollow Core Particle Board for Decoration and Furniture Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m³

- Supply Capability:

- 40000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords