Screwing Into Particle Board

Screwing Into Particle Board Related Searches

Fiber Sheet For Roof Waterproofing Additive For Cement Render Stainless Steel Hot Tubs Stainless Steel Draining Board Aluminum Foil Hot Rail Hot Aluminum Foil Trick Pig Hot Water Bottle Cover Tartan Hot Water Bottle Cover Electric Hot Water Bottle Argos Funny Hot Water Bottle CoversHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Stainless Steel Tank For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Used Foam Board Insulation For SaleScrewing Into Particle Board Supplier & Manufacturer from China

Okorder.com is a professional Screwing Into Particle Board supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Screwing Into Particle Board firm in China.Hot Products

FAQ

- Particleboard industry is currently looking ahead

- so the effective utilization of forest resources and papermaking pulp waste has been paid more and more attention

- Particleboard by product classification

- According to the arrangement of shavings in the slab, there are two kinds of directional and random type

- So for the particleboard formaldehyde release of the situation how to deal with it?

- in fact, after the decoration of the room, such as Chlorophytum, Citrus grandis,

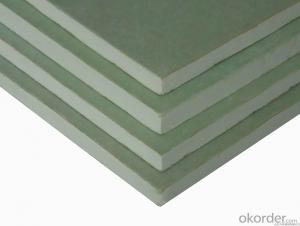

- Particleboard production process requires proper hot pressing pressure

- Hot mold can be used less rubber or rubber, by lignin in the closed hot mold activation flow from the glue, but need to cooling stripping, heat consumption, low productivity, has been gradually eliminated

- Particleboard production requires proper moisture content

- According to the different density requirements of products, hot pressing pressure is generally 1.2 to 1.4 MPa.

- According to the use of points: Class A particleboard; Class B particleboard

- According to the use of raw materials: wood particleboard; bagasseboard particleboard; linseed particle board; cotton stalk particle board; bamboo particle board; cement particle board; gypsum particleboard.

- What are the disadvantages of particleboard?

- in the cutting board is likely to cause the phenomenon of violence teeth, so part of the process requirements for processing equipment higher; not on-site production;

- What create an excellent condition.

- Many furniture manufacturers have re-use of particleboard as raw materials, in addition, directional particleboard is also gradually accepted by consumers