HDPE Plastic Geocell / Geocell Cellular Confinement System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

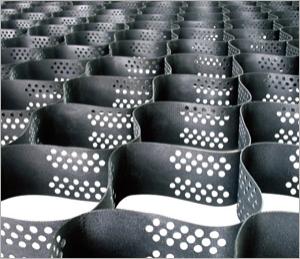

Description Of HDPE Plastic Geocell

Geocell is honeycomb shaped structures using material of HDPE or PP, welded by high frequency ultrasonic.

Main Features of HDPE Plastic Geocell

Geocell Cellular Confinement Systems / Geocell / Geocell systems / HDPE Smooth/Textured Plastic Geocell

1.welding distance:330-1000mm

2.height:50-250mm

3.Textured or Smooth surface

4.Color: black,brown,green

we are one of the largest geocell factory in China.

Specifications of HDPE Plastic Geocell

1.Height:50mm-200mm

2.Welding distance:330mm-1000mm

3.Thickness of sheet: 1.0mm-1.5mm

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Applications of HDPE Plastic Geocell

To stable the roadbed of highway/railway.

To bear the load of dyke, retaining wall.

To improve the watercourse of shallow river.

To support the pipeline and sewer.

To be used as independent wall, wharf and breakwater, etc..

To be used for the regulation of the desert, beaches, river bed and river bank.

IMages of HDPE Plastic Geocell

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q:How do geocells enhance soil confinement?

- Geocells enhance soil confinement by providing a three-dimensional cellular network that prevents soil particles from shifting or sliding. The geocell walls trap and confine the soil, creating a more stable and compacted structure. This confinement helps to increase the soil's shear strength, reduce lateral spreading, and prevent erosion, thereby enhancing its overall stability and performance.

- Q:How do geocells improve the performance of unpaved roads?

- Geocells improve the performance of unpaved roads by providing a stable and reinforced base. These three-dimensional honeycomb-like structures are filled with compacted soil or aggregate, creating a strong foundation that distributes the load evenly and prevents lateral movement. This reinforcement reduces rutting, potholes, and erosion, enhancing the road's durability and longevity. Additionally, geocells help with water drainage, reducing the risk of water accumulation and improving overall road stability.

- Q:How do geocells help with load-bearing capacity?

- Geocells help improve load-bearing capacity by confining and stabilizing the infill material within their honeycomb-like structure. This confinement prevents lateral spreading and enhances the material's ability to distribute and withstand heavy loads, thus increasing the overall load-bearing capacity of the structure.

- Q:Can geocells be used for erosion control on riverbanks?

- Yes, geocells can be used for erosion control on riverbanks. Geocells are cellular confinement systems made of interconnected cells filled with soil, aggregate, or other materials. They provide stability to the soil, prevent erosion, and promote vegetation growth. The cells create a strong and stable structure that absorbs the energy of flowing water, reducing erosion and maintaining the integrity of riverbanks.

- Q:How do geocells enhance the stability of bridge abutments in river banks?

- Geocells enhance the stability of bridge abutments in river banks by providing a reinforced structure that confines and stabilizes the soil. These three-dimensional honeycomb-like structures are filled with compacted soil, creating a strong foundation that can withstand the lateral forces exerted by the flowing river water. The geocells prevent soil erosion and lateral spreading, reducing the risk of abutment settlement or failure. Additionally, they improve load distribution, increase shear resistance, and promote vegetation growth, further enhancing the overall stability of bridge abutments in river banks.

- Q:How do geocells improve the load distribution of soil?

- Geocells improve the load distribution of soil by confining and stabilizing granular materials within their honeycomb-like structure. This confinement prevents lateral spreading of the soil under load, allowing for a more even distribution of pressure and reducing the potential for settlement or deformation. Additionally, the geocells increase the effective stress within the soil, enhancing its load-bearing capacity and overall stability.

- Q:What are the design considerations for geocells?

- Some of the key design considerations for geocells include the choice of material, cell size and shape, cell height, connection strength, and overall stability. The material used for geocells should possess sufficient strength, durability, and resistance to environmental factors. The size and shape of the cells are determined based on the specific application and desired load-bearing capacity. The height of the cells influences the confinement and support provided to the infill material. Strong connections between cells are crucial to maintain the overall integrity of the geocell structure. Lastly, ensuring stability against forces like shear and vertical loading is essential for a successful geocell design.

- Q:Are geocells suitable for use in mine tailings containment?

- Yes, geocells are suitable for use in mine tailings containment. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene that provide stability, reinforcement, and erosion control to various applications, including mine tailings containment. They effectively prevent the spread of tailings, enhance their stability, and reduce the risk of environmental contamination.

- Q:Are geocells suitable for creating walking paths?

- Yes, geocells are suitable for creating walking paths. Geocells are a type of cellular confinement system that can provide structural support and stability to the ground, making them ideal for creating durable and stable surfaces for walking paths. The cells can be filled with various materials such as gravel or soil, which helps to prevent erosion and improve the load-bearing capacity of the path. Additionally, geocells can be easily installed and are cost-effective, making them a practical choice for creating walking paths in various terrains.

- Q:How do geocells help with slope protection?

- Geocells help with slope protection by providing a stable and reinforced structure that prevents soil erosion and slope instability. These cellular confinement systems are installed on the slope surface, filled with soil or aggregate material, and then compacted, creating a strong barrier that retains the soil and prevents it from sliding or eroding. The interconnected cells also enhance drainage and promote vegetation growth, further enhancing the stability of the slope.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Plastic Geocell / Geocell Cellular Confinement System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords