WPC Wood Plastic Composite Natural Colour Slip Resistance to Water Rot Insect

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

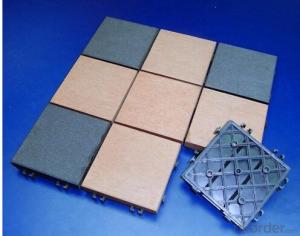

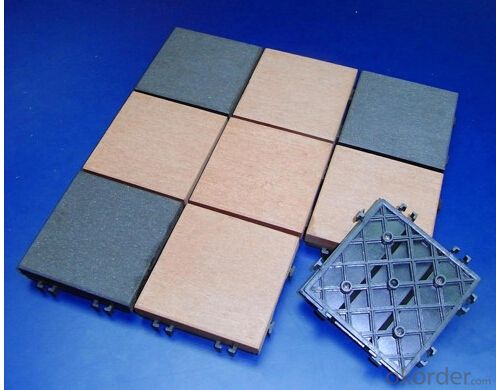

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q: Before the family recently installed a gall bladder of the poor side of the poor recovery of the flower floor, and his family together in the bridge King Jinsheng Li Yang floor to buy. But the baby at home is particularly naughty, things often do not accidentally lost to the ground, the last time a glass are broken, but the floor is not the slightest scratch of what, or very weary and durable. Just want to ask, after the composite floor should be how maintenance? If not care, will not be more easily damaged? More

- Do not need to take care, almost a few years to make wax on the line

- Q: How many square meters of composite floor

- Composite floor prices vary, about 30 yuan floor, there are about 150 yuan floor, because the brand, the quality of the price gap is not large, if the mid-range composite floor should be between 80-100. Cheap composite flooring prices will not exceed 60 yuan / ㎡. (Floor thickness: 18mm) Price 270 yuan -300 yuan / square meter composite imitation wood flooring: the elephant, Feilinger, the Yangtze (floor), the floor of the floor, Thickness: 12mm-15mm) Price 110 yuan -160 yuan / square meters Solid wood flooring: the elephant, Feilinger, Yangtze (floor thickness: 8mm-10mm) Price 260 yuan / square meter Recommended home selection of the floor: Do not choose too Well-known brands, because well-known brand advertising into a great deal. As long as attention to whether through environmental certification can choose. In the middle of the ordinary composite floor: the Yangtze, the new image, Feilin Si (floor thickness: 8mm-12mm) price 8mm thick 75-90 yuan / square meter; 12mm thick 85-100 yuan / square meter. Composite flooring is generally installed by the seller side, you do not need to find someone. The price at the time of purchase you both sides need to be negotiated.

- Q: In life, strengthen the composite floor is mainly used for what place?

- Strengthen the composite floor Fan Dayton end of the rudder full of fine households can be used in many places, such as indoor, office office and so on. On the strengthening of composite flooring In fact, there are many kinds of argument, a lot of information can go to Qijia forum to see. The The

- Q: Recently to decorate the house, want to put the bedroom covered with composite flooring, but do not know the shop composite floor and floor tiles that is good, please give me some instructions, and if the election of the floor to choose a single card into the toilet, What kind of good, the price probably in a lot? More

- Personally feel that the floor is relatively simple and easy to eat, the floor tiles will be cool if the north before heating and heating will be relatively cold, the composite floor to take care of simple prices cheaper than solid wood flooring, the bedroom is recommended or solid wood flooring Better.

- Q: New home decoration! For the floor is not very understand!

- Solid wood is good, but the composite floor is easy to get up with water, but relatively cheap

- Q: What is the difference between composite flooring and tiles?

- To the occasion, the general bedroom and study more suitable for wood flooring. The kitchen, the bathroom is more suitable for tiles. One: tiles: tiles are often said floor tiles. Tiles are cheap, and easy to clean and clean, tiles are also wear-resistant. However, the tiles of the foot feel and decorative effect as wooden floor. Second: wood flooring: wood flooring is divided into solid wood flooring, parquet. 1) solid wood flooring: solid wood flooring is very healthy, environmental protection, decoration effect is good. In the price is more expensive, and not easy to install and maintain, need regular waxing. 2) parquet: solid wood flooring changed the previous physical structure, better stability. In the price, than the solid wood flooring to be cheaper, are middle consumer products. Is the home decoration in the more popular a class of ground decoration materials. 3) to strengthen the floor: to strengthen the floor is the biggest feature of wear resistance is good, very suitable for living room and other places more concentrated, is the wood floor varieties in the cheapest floor, is the working class people first floor decoration materials. However, in the installation and maintenance is very simple.

- Q: Composite wood floor with tiles which tiles which point? Composite wood flooring with the wood floor as afraid of water? If mixed with the words, the bedroom with a wooden floor good? More

- Composite wood flooring and tiles which is good? This is based on personal preferences; tiles in the vigorously better clean up a little, and the composite wood floor at home with the elderly and children when more appropriate, character is also a little warmer!

- Q: Solid wood composite flooring product quality

- Solid wood composite flooring product quality

- Q: Brand also saw a lot of their own. The Home opinion did not agree to say that to buy the nature of the said 礌 紶 紶 cough to change the point of view of the glass is a big brand, said to buy peace of mind that is cost-effective. The Which is good in the end? More

- Nature is better, if not bad money on the election of the elephant

- Q: November to strengthen the installation of laminate flooring, the New Year when the problem, all for some time from the drums Call the business, they say that we use the floor when the water encountered, and the quality of the floor does not matter. I finally bought a house, although the installation of the floor after the taste of formaldehyde, but also to the new house in the New Year, early to move over. Did not expect, and now have to re-buy the floor. And gas and regret, want to tell you that trace of the tube 攮 攮 alone sweeping the shock, buy the floor to be more cautious ah more

- One of the top ten brands of laminate flooring: one of the top ten brands of flooring composite flooring: one of the top ten brands of composite wood flooring: one of the top ten brands of composite wood flooring: One of the top ten brands of flooring: Cicero flooring composite wood flooring one of the top ten brands: Parker floor composite wood flooring top ten trace of the tube 攮 攮 alone one of the sweeps: Kenya floor composite wood flooring One of the top ten brands: Yangtze flooring composite wood flooring one of the top ten brands: macro resistant floor composite wood flooring one of the top ten brands: Kyrgyzstan floor flooring suggest you later on jiuyAomAIZHExIEle

Send your message to us

WPC Wood Plastic Composite Natural Colour Slip Resistance to Water Rot Insect

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches