WPC / WPC Decking / WPC Flooring / WPC manufacturer in China for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

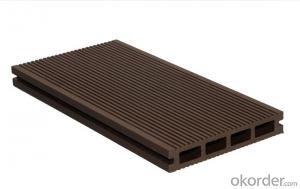

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: Solid wood flooring and composite flooring which is good

- Solid wood flooring is more expensive than composite flooring, but environmental protection and comfort are certainly much better than composite flooring. ~~~~

- Q: Home decoration, prepared in the main sleeper flooring, how to choose it? Ask for more advice

- Solid wood flooring is generally more than 150-1000, mostly 180-480 more, strengthen the 28-280, the majority of the good between 90-180. Different brands of different quality, the process of helium treatment of the heart of the raspberry monk Fuji and environmental protection base trees and other different prices so different, I recommend several brands; solid wood solid wood flooring floor of the living floor, There is the nature of the faith; to strengthen the composite floor of the floor of the elephant, Feilinger these are one of the best

- Q: Strengthen the composite floor of the Americans also use it ???

- Flooring in the United States are FMCG, especially the strengthening of the floor, a few dollars in the supermarket a square, are locked deduction pole pole shot Yao Yue poem super stream, the installation is simple, of course, foreigners more expensive labor costs

- Q: Listen to cloning the floor good care, lazy preferred, Google only found a Cologne floor. Did i hear it wrong, or is it going to strengthen the composite floor? More

- Is the floor of the composite floor is the meaning of "copy" "copy" solid wood flooring look so early that the cloning of the floor and then the so-called Cologne floor drilled a loophole so many people mistakenly think that he is the Cologne trace over the lie Go to the ground to pull the floor to see the original post & gt; & gt;

- Q: My house in addition to the bathroom, balcony, kitchen with other tiles outside the floor, solid wood flooring and too expensive can not afford to feel the room with tiles and cool after a child wrestling also pain, but I heard the composite floor twitch Ji You are willing to use the composite floor of the solid wood composite environmental protection or strengthening, and which brand is also some of the quality of environmental protection is also affordable, please use the sincere answer really grateful, Brand of care do not answer the question added: home with a child, then the solid wood will really be a drop of a pit is not so ugly, waterproof which is better to consider the home with children and the elderly more

- Of course, is a solid wood composite pull, now installed solid wood composite has been catching up with solid wood flooring! Solid wood composite will gradually replace the solid wood flooring!

- Q: We have ceramic floors that are ugly and cracked on a radiant heated concrete floor, we was going to put laminate over but after reading reviews it looks like we need to take ceramic tiles out then lay the laminate or engineered flooring.. Which flooring is better for radiant heat?

- If the tiles are still well secured and just stress cracks, you can go over them with a laminate. Note... I said still well adhered. Same is true with a floating engineered wood floor. But if the tiles are loose at all, they need to come up , the thin set scraped down and the slab smooth . Then you can do a glue direct engineered wood or a floating floor with laminate or engineered. Both will radiate the heat about the same. Any questions you can e mail me through my avatar. GL

- Q: Home with solid wood flooring and laminate flooring which is good?

- Home with solid wood flooring. Strengthen the floor with a density board to do the substrate, MDF is made of wood powder and plastic pressed, airtight, poor foot feeling, impatience, no moisture, formaldehyde emission is high, the surface is decorated wood grain paper, Filled with aluminum oxide wear layer, wear resistance is better. Install the floor after the main problems in the following areas: ① drums ② deformation ③ cracking and so on. Strengthen the composite floor waterproof moisture resistance is poor, so the installation must be done moisture treatment. So must be installed moisture-proof plastic cloth and PE mats, in order to moisture. In addition, the strengthening of the floor is basically no natural wood flooring has the advantages: sound absorption, antibacterial, rich and so fine. In the case of heating, strengthen the floor prone to drum, deformation and other issues. Solid wood composite flooring is not easy to deformation anti-Alice, good maintenance, not Jiaoqi, etc.: ① solid wood flooring substrate is more than Liu amine, breathable, comfortable better; ② with less glue, better environmental protection; ③ surface with solid wood Thin slices, good-looking, the price is generally lower than similar solid wood flooring; ④ it is generally used UV paint coating, but also the use of ceramic paint, wear resistance are better, but not as good as complex; ⑤ not squeamish, good care. It has a good moisture resistance, because its substrate is the use of criss-cross the willow wood pressed from the wood to eliminate the internal stress.

- Q: How about solid wood flooring?

- Not bad, even the home of the security floor of the solid wood flooring, the quality of very good. Personal strong recommendation Oh!

- Q: How is the maintenance of the new floor laminate?

- Buy the floor on the Internet Bell, just paved, the new floor needs maintenance? More

- Q: And the floor of the floor is low, you have to raise the door frame, tile workers do not want to lift the door when the workers, leveling down the door when the pressure down one centimeter of cement, so that the door Can you lay the floor?

- The key is the landlord you do not like to play seesaw, composite flooring is floating on the ground, so in fact the requirements of the ground may be higher than the solid wood floor.When you are uneven floor to the floor is large and small seesaw. The basic decoration can do it, your Haifa fried box Curcuma Valley Feng greedy fuel Kai decoration team has the final say or you have the final say ??

Send your message to us

WPC / WPC Decking / WPC Flooring / WPC manufacturer in China for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches