WPC/PVC Furniture Foam Board/WPC Sheet Extrusion Machine Line/FOAM BOARD MAKING PLANT

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application

1 Exhibition desk, Shelve in supermarket

2 Advertisemen Board and sign board

3 The advertisement sheet for printing, engraving, cutting, sawing

4 Architectural decoration and upholstery

5 Decoration for partition wall and shopwindows

WPC/PVC Foam Board Production Line Production Flow:

Material batching mixing_extruding_molding_vacuum calibrating and cooling_hauling_cutting- final WPC foam boards

Popular Surface Treating Ways:

- Lamination

- Hot stamp printing

-Embossing

WPC/PVC Foam Board Production Line Main Machine

-PVC mixer

-PVC WPC foam board production line

(Including autoloader, conical twin screw extruder, mould, calibration table, hauling machine, auto cutter- stacker)

- Lamination machine(for furniture foam board)

- Hot stamp printer (for furniture foam board)

- Waste rusher& PVC miller

- Air compressor

- Water chiller

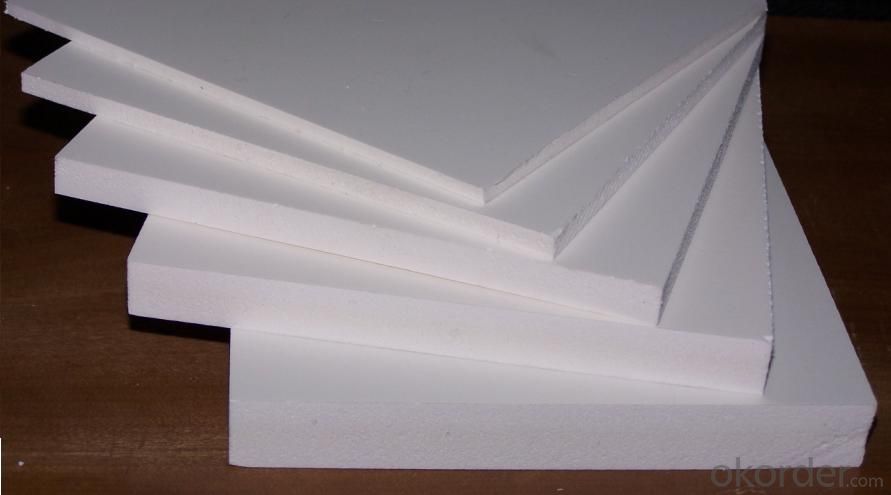

PVC Foam Board/Sheet description:

| 1 | Product | PVC Foam board/sheet/panel |

| 2 | Standard size | 1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm and so on |

| 3 | Thickness | 1~30mm |

| 4 | Density | 0.3~0.9g/cm3 |

| 5 | Brand | Dio (OEM) |

| 6 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

| 7 | Executive standard | QB/T 2463.1-1999 |

| 8 | Certificate | ISO9001 |

| 9 | Weldable | Yes |

| 10 | Foam Process | Celuka |

| 11 | Packing | Carton box or wooden pallet packing |

| 12 | production capability | 11000 pcs per month |

| 13 | Life Span | >50 years |

| 14 | Flame retardance | self-extinguishing less than 5 seconds |

Features:

1. Special embossed effect and strong underlay structure.

2. Excellent draining function

3. Good Anti-slip function and shock absorbing performance.

4. Highly anti-ripping surface, natural touch feel, tensile

5. A wide range of patterns, styles, and colors available to match indoor decoration

6. Multiple uses: uses beyond the lining of kitchen and bath shelves and drawers

photos:

- Q: Behr has special paint, can this be done with other paint?

- I've been in the buisness for a long time, and no matter the paint, or even the number of colors, what your talking ab out is a faux finish. In the technique, you'd roll on a color, then apply even wax paper, saran warp, plastic drop cloth, usually wrinkled already, and gently remove it. The effect would show all the lines and creases in the finish. Work in small areas at a time,,,,no larger than 3 x 3 to maintain some control, and the patterns will be different everytime, b ut you should blend when you can, and keep the base coat wet long enough to accomplish the finish you want, whether is that, rag roll, sponge, feather, etc. There are hundreds of web sites, hundreds of books, and dozens of techniques. I use all of them. Rev. Steven An added note,,, DO NOT apply color to the sheet, always to the wall and use the remove technique not apply technique

- Q: I want to build a table and for the top i would like it to be a sheet of cloudy or frosted plexiglass or perhaps acrylic about 3' x 6', so light can shine through it. Which is cheaper? Where can i find them?

- You could google translucent plastic sheet and see if you get any products of interest. Alternately, you could purchase your plastic sheet and have someone hit it lightly with a sandblaster. If you create an artistic pattern or shield to go over part of the plastic, you'll get a picture where the clear plastic is surrounded by cloudy plastic. Good luck!

- Q: Can plastic sheets be used for agricultural purposes?

- Yes, plastic sheets can be used for agricultural purposes. They are commonly used as mulch to control weed growth, conserve moisture, and regulate soil temperature. Plastic sheets are also utilized in greenhouse farming to create a controlled environment for plants, protect them from external elements, and enhance crop yields.

- Q: Are plastic sheets resistant to staining from cleaning agents?

- Yes, plastic sheets are generally resistant to staining from cleaning agents.

- Q: I need a piece of flat sturdy plastic about 1/8 thick. Does anybody know where I can buy this? I dont want plexiglass, its too expensive.

- places that sell glass/mirrors, etc usually have acrylic that they can cut for u

- Q: Can plastic sheets be used for art or craft projects?

- Yes, plastic sheets can be used for art or craft projects. They are versatile and can be easily cut, painted, or molded into various shapes and forms. Plastic sheets are commonly used for creating stencils, masks, or templates, and can also be used as a base for mixed media art or as a protective covering for artwork.

- Q: What are the different types of plastic sheets available?

- There are numerous types of plastic sheets available, including acrylic, polycarbonate, PVC, ABS, HDPE, and LDPE. Each type has unique properties and characteristics that make them suitable for various applications such as signage, packaging, construction, and fabrication.

- Q: Can plastic sheets be recycled into new sheets?

- Yes, plastic sheets can be recycled into new sheets through a process known as plastic sheet recycling.

- Q: How much would it cost to replace a scratched plastic sheet floor in a kitchen? (approx 3x4 m2)?

- Not enough info to tell you. If you're doing the work yourself, go to a home store and price the sheet goods you want to replace it with. Read the installation directions to see what you have to do, and buy or rent the appropriate tools. Most home stores can give you plenty of advice on what you need to do. If you're not going to do the work, call some handymen and get some bids. Check their references and go with the one you like best.

- Q: Can plastic sheets be used for hygienic wall cladding?

- Yes, plastic sheets can be used for hygienic wall cladding. Plastic sheets are often chosen for wall cladding in hygienic environments such as hospitals, laboratories, and food processing facilities due to their non-porous and easy-to-clean properties. They provide a seamless and smooth surface that is resistant to moisture, bacteria, and mold, making them an ideal option for maintaining hygiene standards.

Send your message to us

WPC/PVC Furniture Foam Board/WPC Sheet Extrusion Machine Line/FOAM BOARD MAKING PLANT

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords