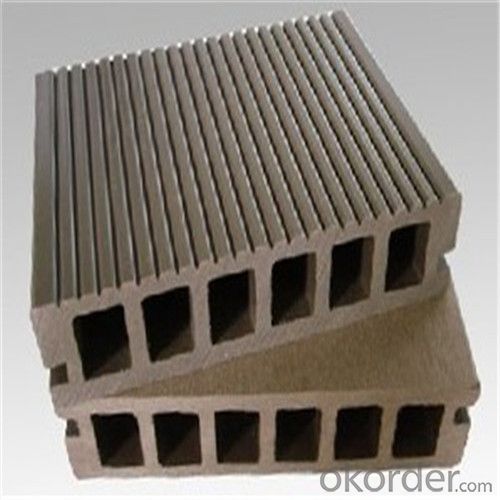

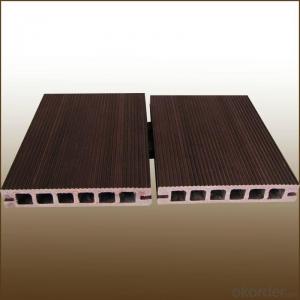

WPC Hollow Deck Tile Hot Sell Beautiful Decking China 2016

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

Product Name | 140mm*25mm Wpc Decking for outdoor |

Sizes | 128x23mm, 130x14mm, 140x21mm, 150x20mm, 157x21mm, 185x30mm, 225x16mm, Optional |

Length | 2.2m, 2.4m, 3m, 3.6m, 5.8m, Optional |

Colors | Green, brown, red, grey, black, red brown, teakwood, redwood, red, yellow. Optional |

Surface | Sanding, brushing, embossing. |

Component | Poplar wood fiber + HDPE + additives. |

Warranty | 20 years |

Certificate | CE, ISO, SGS |

Packages | Carton, pallet |

Applications | Park, Garden, Lawn, Balcony, Corridor, Veranda, Patio, Garage, Bridge, outdoor bar, Boardwalk, Playground, Pool surround. |

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Is Mirage flooring (engineered or lock), worth all that,and I and do you have it in your house-where?

- We installed a floating laminate floor years ago and love it. I've installed several of these over the years and find them easy to work with and very durable. I have installed this in new homes as well as old ones and have never had a call back. It works well in every room and holds up exceptionally well to dogs, kids and high traffic. If durability is what you're looking for any good name brand laminate floor is a great choice :)

- Q: Composite wood flooring how much money a flat? What are the disadvantages of floor and floor tiles?

- If it is geothermal, it is recommended to use tiles, will be higher than the floor temperature

- Q: In the old composite wood flooring and then add a layer of elephant composite wood flooring is possible, will not exceed the formaldehyde content

- Any brand of any floor will contain formaldehyde, formaldehyde not only from the glue, but also from the paint. Formaldehyde emission in accordance with national enforcement standards is 1.5mg / L, better than this standard Caixing. Decoration process, you can release a lot of formaldehyde things, such as home, carpentry, paint ... ... it is inevitable to ensure that the standard. You can ask the business, floor production is used in what glue, such as water-based glue and the like. General water-based plastic market price in 2000 or so a ton, and professional floor glue about one ton, such as the international market more professional floor glue is Finland's Tail glue. And paint, then, relatively good is the German Fu Fu paint.

- Q: My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and open the door to open the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, What did not buy, is empty house, there are ten years old furniture. Here to ask, now how can I do, how long this taste can be distributed more

- To find indoor purification in addition to a taste can be better, but can not solve the fundamental problem, it is said to ten years to finish. View original post & gt; & gt;

- Q: My house is a guest, and the middle is separated by curtains. The election of the bed, wardrobe, are white, above the embellishment of the frender of the spoons of the pity, Light color? Specific point is the best. Questions added: the top of the wall is white more

- Choose what color of the wooden floor depends mainly on the windows and doors and the color of the wall, the wall and the window and window cover is white, then very casual, and what kind of color wood flooring is not ugly, white with a good color. If the window and window sets of color is red, then the wood floor will try to choose the color of the deep point, so from the community feel more comfortable. There is an important factor is how your home floor, how to light. Good lighting on the random, the light is not good to try to choose a shallow warm color of the floor. After all, or to a little harmony and the top of the wall are white, furniture is white. So that the color composition of the home has been a lot of light, I recommend a dark color of the wood floor, so from the visual look is more comfortable. For example, a balloon if you do not catch it, then he will fly away. We are the same, the family of what are white, it should be a little deep choice of wood flooring, so that you can put the entire tone pressure. Another point to note is that your home on the floor, if the light is not good for the wind, then you can not use too heavy color, this point you own grasp it. Ha ha

- Q: Buy the composite floor, relatively cheap, when the sweep is dry with a wet mop dragged, but after the towing or Gong Gong drink drink 鼙 estimated Russia and Taiwan have a watermark with a dry mop can not all drag the watermark and other watermark dry To show a little bit of speculation that is not clean I was not used to clean the water there is no such situation with friends to support more ah

- When cleaning the floor, please use a vacuum cleaner or wring the rag to swipe, not rinse with water; floor use absolutely prohibited water soak, if the accident should be dry with a dry cloth in time, and naturally dry, is strictly prohibited to use electric heater drying or in the sun Under the exposure to avoid hard objects scratched the floor, moving furniture and heavy objects can not be hard to push and pull. Should not use iron furniture legs directly contact the wood floor surface; in the table and chair stool and other places with the floor with the cushion, To increase the degree of friction floor

- Q: After the floor of my house is finished, the flooring company says it does not need waxing is compounded, is it like this?

- Do not need a composite floor strength is high 2 composite floor surface is not a solid wood material but posted a layer of skin, do not need special protection.

- Q: Will the professionals, strengthen the composite floor really can not touch a drop of water? If it is true

- Who said cheating you can

- Q: Yesterday finally closed, and went to see the building materials. In the iconic floor set a bit where the activities, then did not pay much attention, only know that the iconic floor is not wrapped in the foot of the night to find home, the list also wrote a buckle above (every 0.8 meters 40) Want to know what the buckle is used to do, my house construction area is 85 square meters, the use of the area is probably more than sixty, the kitchen bathroom is not shop, Floor, how much buckle, please professional to answer, very grateful. More

- Buckle is generally used in the door to the mouth of the place or the direction of the floor to change the place with a copper strip of aluminum

- Q: My home decoration is Chuang floating off spring curled turtle Tong Tong Kun light-colored composite floor, so the floor seam a little bit of dirt, then it looks black, with a mop can only rub the floor, clean the floor seam, I have tried With a wiping cloth wrapped with a finger of a seam of the pull, so the floor is a clean seam, but did not rub half of the tired half. Do not you know that there is no merit to solve this problem? The More

- You use chopsticks and the like above the thing wrapped around the cloth with two hands try to drag

Send your message to us

WPC Hollow Deck Tile Hot Sell Beautiful Decking China 2016

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords