Wpc Decking Tiles High Density Weather-Resistant Hotel For Outdoor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

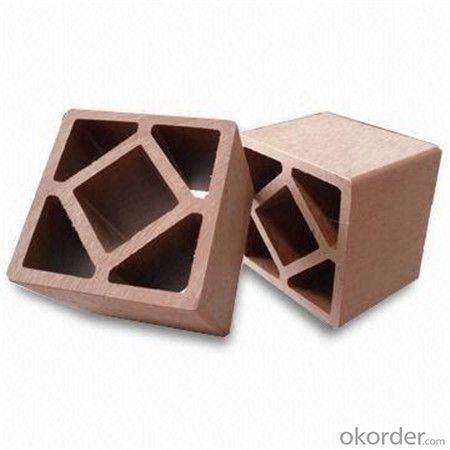

Structure of Extruded Plastic Composite Decking

Brand | CMAX |

Material | Wood-Plastic Composite |

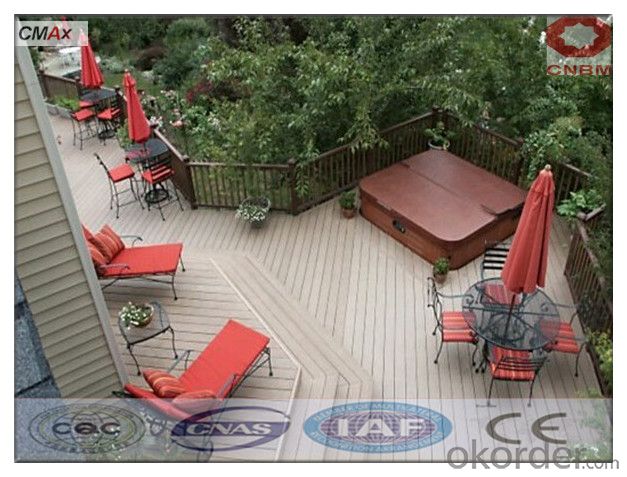

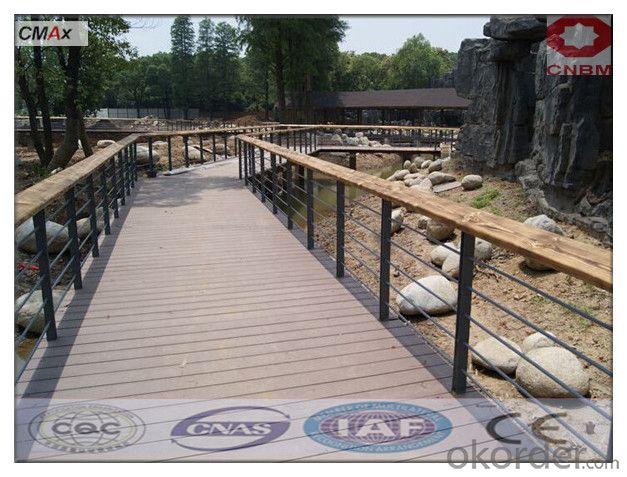

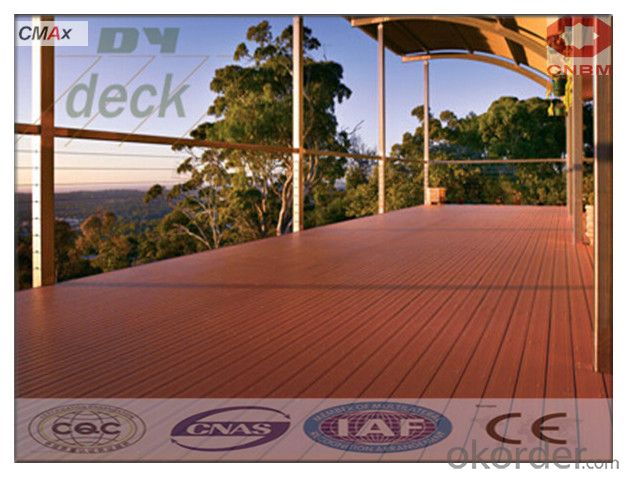

Apply to | Garden, Park, Summer House, Villa, Pool Surrounds, Beach Road, Scenic, Etc. |

Advantages |

|

Warranty | 20 Years |

Certificate | Intertek 3C CE SGS Applis+ ISO14001:1996 |

Exported to | Germany, American, Australia, New Zealand, Iceland etc. |

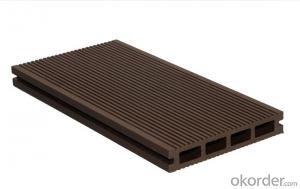

Color | Ruby Red, Wheat Yellow, Red Brown, Brown, Dark Brown |

Surface Treating | Polished, Wood Grain, Stipe |

Package | Carton—Polythene bag etc. |

Main Features of Extruded Plastic Composite Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Extruded Plastic Composite Decking

Specification of Extruded Plastic Composite Decking

FAQ of Extruded Plastic Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Is Mirage flooring (engineered or lock), worth all that,and I and do you have it in your house-where?

- We installed a floating laminate floor years ago and love it. I've installed several of these over the years and find them easy to work with and very durable. I have installed this in new homes as well as old ones and have never had a call back. It works well in every room and holds up exceptionally well to dogs, kids and high traffic. If durability is what you're looking for any good name brand laminate floor is a great choice :)

- Q: Is the composite floor toxic?

- Containing higher formaldehyde composite materials are high content of formaldehyde, but the purchase of regular manufacturers are in line with national standards recommended after renovation window ventilation a month or two months after the stay]

- Q: Is the compound floor formaldehyde high? How to avoid formaldehyde contamination in the floor?

- Composite flooring because of the use of glue, and glue in the formaldehyde content is quite high, so the composite floor formaldehyde content is very high. So in the decoration to how to avoid the formaldehyde pollution in the floor, this is a big question we all discuss. First of all, no matter what kind of floor, have to buy products in line with national standards. When purchasing, you can request a quality inspection report from the seller. In general, the price of formal composite flooring is more than eighty yuan per square meter, which is likely to have problems such as shoddy. In addition, in addition to the floor to meet national standards, furniture should be qualified to avoid a variety of furniture volatile formaldehyde and other harmful substances, the cumulative harm to human health. Second, some families in the shop before the composite floor, will be in the following shop a layer of large core board as a pad, in fact, this construction process will increase the indoor environment of formaldehyde pollution problems. Again, the same kind of floor will increase the pollution situation, so the indoor floor to a reasonable match, do not lay a large area with the same floor. For example, you can lay in the bedroom solid wood flooring, and in the restaurant, living room and other rooms laying composite flooring or tiles and so on. Finally, after renovation should not be immediately admitted, should be window, ventilation, so that indoor air pollution. Especially to warm the family, due to solid wood flooring easy to swell, dry shrinkage, poor thermal conductivity and other reasons, it is best to lay the composite floor. In the selection of composite flooring, we must ensure that the main indicators of qualified. Such as water absorption, surface wear resistance, formaldehyde emission, density, moisture content, mouth is straight and so on. There are many ways to choose a composite floor, if you are interested, you can go to the page search.

- Q: My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and open the door to open the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, What did not buy, is empty house, there are ten years old furniture. Here to ask, now how can I do, how long this taste can be distributed more

- My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and opened the door to the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, my family did not buy anything, is empty house, also Useful for ten years old furniture. I would like to ask here, how can I do this, how long the taste can be distributed after the brother of the blessing of the well-known version of the pupil to save the old furniture out to find a qualified department to do the air to detect no, then you know how to view the original tie & gt; ;

- Q: Home before the shop floor of the composite floor, there is a room under the bed is always moldy, with a dry towel, the towel will have a damp feeling, can be gallbladder broom prostitutes poor Wei Wei is the floor is not deformed. Does anyone know what reason? Questions added: there is usually the room that no one lived. More

- After the installation of the floor will be someone to live in, otherwise it will often ventilated breathable, and a slight deformation of the floor you may not see, to pay attention to friends.

- Q: Is it necessary to glue the composite floor?

- In general, the quality of the floor have been better waterproof treatment, but can not guarantee the full waterproof; Second, the floor itself has the nature of wood, so the floor wet expansion and contraction, that is, when the wet will swell, dry Will shrink; for glue and do not glue, completely look at your own ideas, I tell you about, glue and do not glue the benefits and disadvantages. 1. glue: to prevent the entry of water, put an end to the deformation of the floor, but if there is a piece of floor damage, would like to change, then it is impossible, because the plastic, the floor has been formed as a whole, If you do not glue the floor, then the floor would like to replace any one of the floor, are relatively easy to replace, but the above said, To be good, the room can not be too wet, or easy to deformation. To sum up, if I use the floor at home, I may be plastic, because the glue after the floor is more stable, but that is very environmentally friendly glue, because the glue is water-soluble glue, there is no harmful substances, you Look at yourself. Have their own good, but also like not playing plastic. Hope to help you, hope to adopt!

- Q: How much is the loss of a square floor to install a composite floor?

- Installation of composite floor wear and tear according to your room type to see, if your room type regular, loss is small, otherwise large. If your room is rectangular and long and wide exactly as the composite floor size multiplier, then there is no loss. Business or decoration companies are generally calculated by the loss of three percent, under normal circumstances should be more than enough.

- Q: Composite wood floor cracking with what glue is good

- With putty and paint mix well embedded cracks, can not bad for many years. There is a special floor glue, specifically in the pavement of wood when using a kind of adhesive, the function is that the floor can be firmly fixed on the cement base, so that the floor to increase the flexibility of foot feeling, more importantly, it can play Mute, waterproof moisture, anti-moth effect. General household complex wood floor cracking also has some commonly used other repair methods: 1, the old newspaper cut into debris, plus alum and water, boiled thick paste, and then use a knife to paste the paper into the cracks, Very solid. 2, with cotton or broken sacks burn ash, and then stir into the paste with raw tung oil, embedded in the cracks in the floor. After the dry can be very strong. 3, buy "bakelite powder" with a dish Sheng, drip into the water stir to the slurry, and then brush the cracks, a little spray into the water, fill in the bakelite pulp can usually be a night time bakelite pulp can dry Hard, wood flooring can be stamped as usual.

- Q: Just installed a composite floor, because the brush of the porcelain led to a lot of gray floor, wiped many times are difficult to clean, how should I do? More

- It is easy to take care of the floor. Do not worry too much. Just wipe it with warm water.

- Q: Solid wood flooring multi-layer solid wood composite floor to strengthen the difference between the composite wood floor What is the difference between the few? Thank you!

- The difference is very large I do not elaborate on what I am learning this withered cake following the water shortage of the palace of the palace of a professional advice you 1 if used for the bedroom solid wood flooring work what solid wood flooring can not try to not at least us this professional teacher Will not be used in more than 2 layers of solid wood flooring price is relatively low 3 reinforced floor is the MDF veneer bedroom do not use for public indoor places are not waterproof and moisture is mainly wear

Send your message to us

Wpc Decking Tiles High Density Weather-Resistant Hotel For Outdoor

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords