WPC Decking Tile High Density Solid Outdoor Waterproof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Extruded Plastic Composite Decking

| Company introduction: | As a professional manufacurer of composite wood plastic decking, we are specialized in producing& promoting environmental friendly composite wood plastic outdoor decking for years. Our sales network covers all over the world, and we've been proved as a trusted supplier to all our customers. For all the buyers who choose our products, you have our guarantee on both quality& service. |

| Material: | 60% bamboo/wood powder 30%HDPE 10% non-hazardous chemical addives |

| Features: | WPC Decking Tile |

| Available finish: |

Brushed (Smooth), sanded or grained

|

| Colors Available: |

White,Black, Brown, Gray& Teak or customized

|

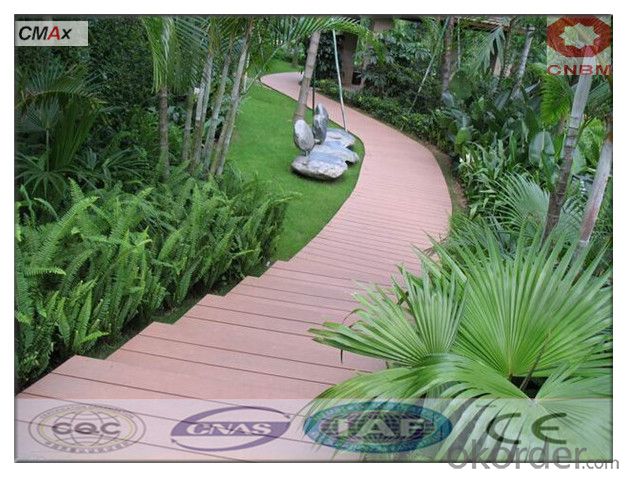

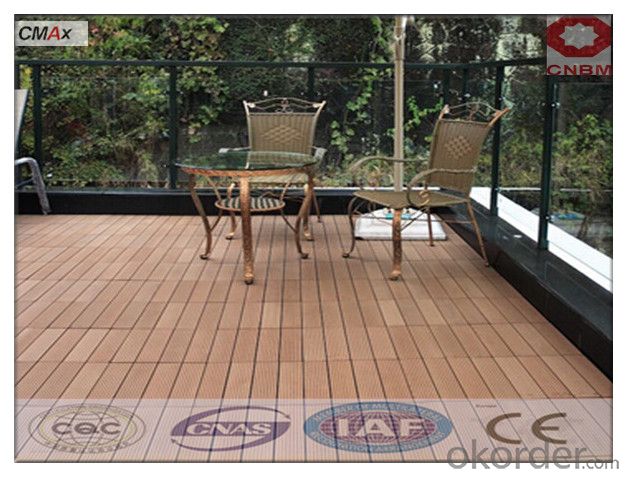

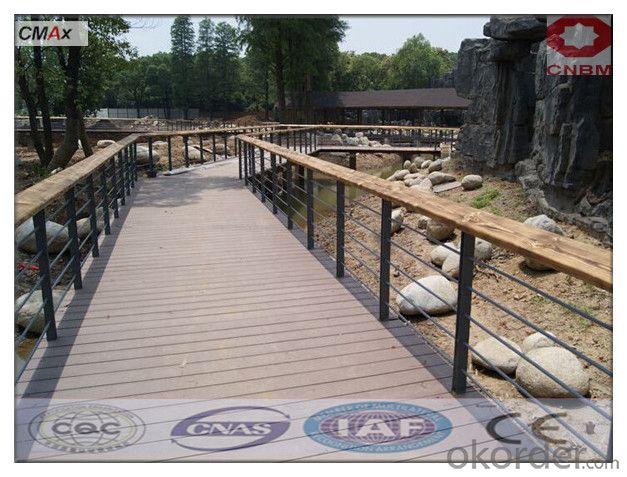

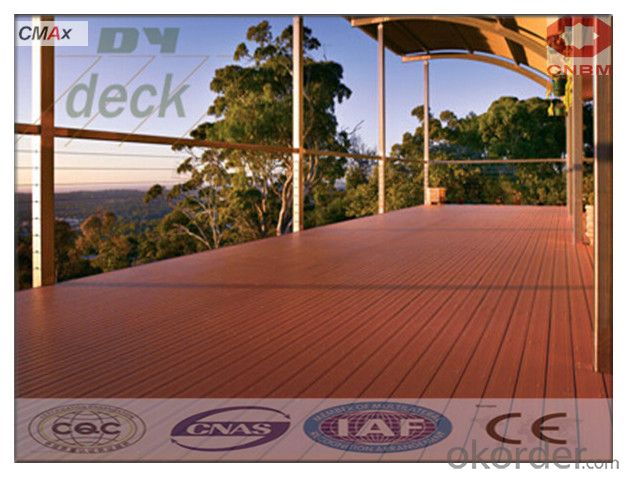

| Applications: | Home& Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground and so on. |

| Certificates: |

CE&ISO&SGS

|

| Size: | 300x300x22mm |

| Finish: | grooved&sanded&grained |

Main Features of Extruded Plastic Composite Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

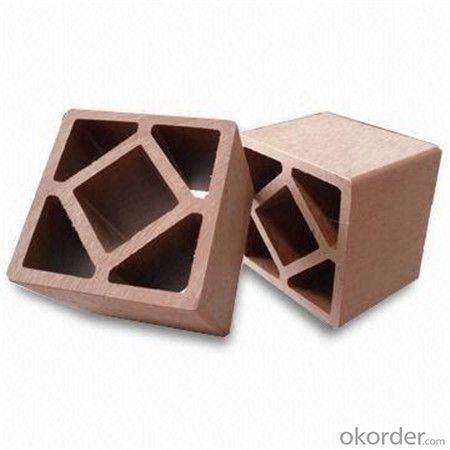

Picture show of Extruded Plastic Composite Decking

Specification of Extruded Plastic Composite Decking

FAQ of Extruded Plastic Composite Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: How long will it change? The quality of those brands on the market is so durable? More

- See how you use it.

- Q: can engineered flooring be used in a bathroom?

- Yes.. they can be so used.. but remember that water on an engineered flooring is not the best and in a bathroom, a flooring is more suseptible to having water on it.... I have always had tile in a bathroom and that is what I would recommend.. of if tile is not feasible, a good linoleum type flooring

- Q: In life, strengthen the composite floor is mainly used for what place?

- Good point of the home shop, there is the office, almost used in the plant workshop. We give the Expo News Center and the administrative center is used upscale. [Expo special for the floor] - [Bell floor] rich and elegant series of Bell flooring OKorder Fan Changdun end of the rudder full penalty house Mall [search "Bell floor", NO.1 is us】 Expo special for the floor - Bell floor Rich and elegant series, elegant taste, starting from the foot

- Q: Accidentally put a large pot of water overturned on the laminate flooring, almost with a dozen minutes to dry with a cloth, will not appear drums ah, worry! Question added: is the European people to strengthen the composite wood flooring more

- Will enter the water swelling moldy

- Q: Is the surface of the composite floor smooth or not smooth? Ask the professional to give the correct answer.

- Multi-choice matte, that is, the surface does not look very smooth kind of.

- Q: Composite flooring installation requires tools,

- Wooden floor installation requires the following tools: Power tools: hammer, pistol drill, marble sawing machine, curve saws, steam pump, steam gun, electric planer, mill, belt sander. Hand tools: hand saws, knife saws, fountains, steel tape, angle ruler, pencil, pull rope, hammer, ax, rubber hammer, punch, scraper, screwdriver, pliers, flat chisel, planing, Special tools: move the hook, tighten the hook. Wood flooring installation process should pay attention to: 1, wood flooring can not buy that shop, should be opened in the new home after a period of time and then shop, so that the wooden floor to adapt to the new environment. 2, do not think that the wood floor can not contain water, in fact, left the water, the wood floor becomes very hard, at the foot of the feeling is not the same, so to keep the wood floor water content of about 14%, of course, this is a professional tool inspection of. 3, wood grille and the ground between the grass-roots should retain a certain gap (primary school textbooks to teach us, to know how to stay a seam), to ensure that the entire ground dragon air patency, do not use cement mortar plug to fix the wood grid In order to use the mattress method, the wooden grille shall be firmly fixed to the ground with nails. 4, shop wood flooring should be cleaned before the wooden grille, sprinkle with moisture-proof powder and pest control powder. This is to prevent insects from eroding the wood flooring material and destroying the structure of the wood floor. 5, nail wood floor nails must use twist nails, first in the mouth of the mouth oblique drilling (holes should be perpendicular to the length of the floor), and then into the wooden grille, or the use of the process is likely to cause loose wood flooring. 6, after the laying of wood flooring to use cardboard, old sheets or old mats and other cover protection. The purpose of this is to protect the original installation of the wood floor structure, firm its structure.

- Q: How to stitch the composite floor, I put the two sides of the long side of the board again how to fight is not fight it? And later the two boards on the top of the interface alignment fight, the results can be flattened can be inserted into the half of the damage Geng indignation of the siege of the bargain to fall into the next can not get into the next, may be the board Too long in this way wrong, please experts to help you! Xiexie problem added: more

- Oh, simple ah, carefully study the complex floor of the mouth, in line with the floor a lot of connections, can not elaborate, carefully look at their own board like

- Q: We had bought some Virginia Millworks 1/2 thick hand scraped engineered nail down flooring for our kitchen. I had asked the guy at Lumber Liquidators where we bought it from if I needed to take the flooring out of the boxes to let it acclimate and he said no, that I could leave it in the boxes. When we got it home all we did was remove the plastic wraping from the boxes and then let the boxes sit side by side, not stacked, in the kitchen. We don't have a lot of space to leave the flooring out anyway. I then got sick for a while so everything sat in the kitchen as we left it for 3 weeks. I'm better and ready to lay it down this weekend but I just read that if I don't have a moisture meter to test the moisture content then I should lay the flooring out of the packaging for 7 days. Should I still do that or do you think having the flooring resting 3 weeks in unsealed cardboard boxes is fine? It's going down over a raised wooden sublfoor with red rosin paper, if it matters. Thanks in advance.

- You should be fine. Moisture testing is generally done for new construction since subflooring can be exposed to the weather and it will take a long time to dry properly.Unless of course your floor has been exposed to these conditions,which I don t think so..The only thing I would ve done was to open the boxes, but thats generally done when acclamating the wood for a 72 hr time frame.Rosin paper is fine.. As far as cleats or staples are concerned, that should be check w/ the manufacturer. Staples are now usually ok from the makers , but make sure 1st, you don t want to void your warranty. The length of the staple will be specified too. To drive staples there are 2 types of guns you can use.The stand up and drive them in or a special trigger type gun that you are on your knees and shoot them in. This is the method I prefer w/ the engineered wood since its easier to set the wood in place and staple. Don t forget a 10$ pair of knee pads. Any other questions you can e mail me thru my avatar GL

- Q: Recently to my house for decoration, I now tangled in the shop solid wood flooring or floor tiles. I heard that the solid wood composite floor of the viscose contains a lot of formaldehyde, and three or five years are volatile, but I also like the twitching of the defensive flossing gong skull Geng Gong wooden floor feeling. Solid wood floor even if the price is too high to take care of, give up directly. What should I do in the end? Hope that people of insight can give pointers one or two, grateful! More

- Solid wood flooring is certainly good, but the composite are used to recover wood mixed with compressed, the body is certainly not good, it is recommended not to use, simple and affordable point with tiles, like a little bit of point plus point wave, the bedroom can buy some winter Carpet, very cheap. The The

- Q: My place where small, something more, had their own shop composite floor, do not know how to shop. Consult the knowledgeable master to help give pointers about, thank you! More

- Ready to hammer, and a board, each board to fight up when there will always be gaps, with a hammer pad with a knock on the board, the raft razed the drums can not directly knock on the floor, the floor will be knocked on the floor , Skirting line, then directly with glass glue it, a simple point

Send your message to us

WPC Decking Tile High Density Solid Outdoor Waterproof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches