WPC Decking/HOT SALES WITH CE Wood Plastic Composite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features of the WPC Decking:

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

8. Easy to install and clean

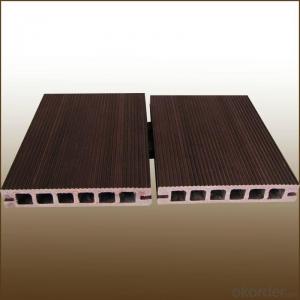

Specification of the WPC Decking:

component | 30%HDPE(Grade A Recycled HDPE) 60%bamboo/wood fiber component 10%chemical addatives New material capped outside |

Size | 140X20mm |

Design | Solid decking |

Length | 2.9m/pc standard length, also from your required |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE,Walnut,graystone,Cedar,Rosewood) and we can adjust the new color according to the order requirement |

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate,"REACH"Test Reports by SGS; Intertek Test Report by ASTM standard..etc. |

Images of Co-extrusion WPC Decking:

FAQ of Co-extrusion WPC Decking :

1. Available Colours?

5 regular colors to choose ( IPE,Walnut,graystone,Cedar,Rosewood )

2. How to Install?

3.Treatment for Option

- Q: Is it good for solid wood flooring? Tangled. The

- On the foot feel is certainly solid wood flooring is better, but the solid wood flooring care more trouble, especially for the use of the North, easy to crack. Solid wood flooring is also called multi-layer solid wood flooring, is made of solid wood cut into pieces and then staggered. There is a little sense of foot, but the multi-layer solid wood can not be polished refurbished, the surface of the veneer case of hard objects is extremely easy to damage, and solid wood flooring can be polished several times after re-painting, renovation and the new floor is the same, and Good wood flooring is a certain value of the property. The price gap between the large, solid wood composite in about 180 to 300, a little better solid wood flooring in more than 300 to a few thousand dollars. In general, is to see your personal preferences and economic strength.

- Q: Home before the shop floor of the composite floor, there is a room under the bed is always moldy, with a dry towel, the towel will have a damp feeling, can be gallbladder broom prostitutes poor Wei Wei is the floor is not deformed. Does anyone know what reason? Questions added: there is usually the room that no one lived. More

- If it is solid wood flooring, there may be long hair, but first of all to find out the corner of the wet moldy reasons, usually such a situation there are several possible, 1, the ground back tide, waterproof layer did not do well, Pipe water leakage, 3, the ground water is not good, the ground water into the wall solid wood flooring maintenance of solid wood flooring to do moisture maintenance, in addition to a simple timely window, often ventilation, there are more professional methods: Care. Should be half a year or a year to play a wax, so you can make the solid wood flooring to avoid the rainy season when the invasion of moisture, so as to achieve the purpose of extending life. Usually in the care of solid wood flooring should also be careful not to let moisture into the solid wood flooring. When found solid wood flooring surface mildly when the time can be used in a timely manner with a soft bleach to 1: 3 dilution ratio of mixed wipe, and then wipe clean cloth.

- Q: What are the shortcomings of the bright composite floor?

- The unique structure of the solid wood composite flooring is an important reason for its superior performance. At the same time, such a structure also makes it in the production process than to avoid the use of a lot of glue, solid wood flooring each layer is glue glue. Currently on the market, solid wood flooring is divided into three layers with multi-storey (5 or 7). The more layers, the greater the amount of glue used.

- Q: This type of floor to hear someone say good. But the price is not expensive? More

- Solid wood flooring are expensive, the specific price depends on what you buy wood, and to buy the floor of the market is also concerned about the high-end places will drive up the price is relatively high I suggest you buy solid wood or do not buy composite flooring is better, under the composite floor on a layer of moisture-proof foam paper, the elderly have children at home, it is not warm, especially children like summer barefoot will be cold. If you do not like the traditional floor of the kind of wood, then there is a kind of smart buckle floor, the price is more expensive, the actual nature and the composite floor almost, but will be a gap between the cement and the ground, and smart The thickness of the floor is thicker than the rest of the floor, because every floor of the floor is supported by a few points, and the naked eye may look thicker. So light foot on the floor will not be damp cold, I see the price of about 300 to 800 per bucket arm Juju bracelet with the delivery of square meters have, I value the wood is a bit expensive for me, Did not buy My home now buy Acacia wood is the traditional solid wood flooring, is bought last summer, the first batch of goods in the high-end building materials market is more than 500, the number of buy less, the nearest place in another place to buy, is the general wholesale market , After the price is less than 250, the quality is the same, so before buying things or shop more important than three.

- Q: Hello,We had an engineered oak floor installed in our home two weeks ago. The floor was glued down over the cement slab. What we have noticed is (1) there are a lot of gaps between the slats (some as big as 1.5 mm); and (2) there is one area where the glue did not stick and now the wood is lifting. This area is in the middle of the entry hallway and we hear a hollow sound when walking on this place (it can be pushed down by hand). My question is are these normal or do we need to contact the installer/dealer to have something done or complain? Thanks in advance for your advice.Jim

- I'd start by getting the installer back in to see your problem. It may be an easy fix.

- Q: We have ceramic floors that are ugly and cracked on a radiant heated concrete floor, we was going to put laminate over but after reading reviews it looks like we need to take ceramic tiles out then lay the laminate or engineered flooring.. Which flooring is better for radiant heat?

- If the tiles are still well secured and just stress cracks, you can go over them with a laminate. Note... I said still well adhered. Same is true with a floating engineered wood floor. But if the tiles are loose at all, they need to come up , the thin set scraped down and the slab smooth . Then you can do a glue direct engineered wood or a floating floor with laminate or engineered. Both will radiate the heat about the same. Any questions you can e mail me through my avatar. GL

- Q: Shop the world solid wood flooring

- Composite flooring generally do not need much effort to maintain, pay attention to timely dust, no hard objects impact, no corrosive detergent cleaning almost. Or you make a phone call to the World Friends, looking for after-sales service, to the home to be a special maintenance. They are professional. So that the floor to wear a flattened flattened to encourage Taiwan to support the age of platinum is also a little longer.

- Q: Multi-layer parquet, for geothermal, when the shop to shop moisture-proof pad? why? Do you want to play keel?

- (Generally manufacturers will lay the floor in the bottom of the laying of radiation film also play a role in moisture, the ground is not recommended to do self-leveling uneven) wood composite floor does not need to be Playing keel

- Q: Sales master laminate flooring master said that do not have to do to promote the production of the floor, the floor of the master said, "Strengthen the composite floor to do curing to maintain its long." No search for the answer. Please have experienced master answer. Question added: Will the use of conservation to strengthen the composite floor. More

- Should be done warranty, and good

Send your message to us

WPC Decking/HOT SALES WITH CE Wood Plastic Composite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches