Geotextile Factory Woven Fabric Anti Mat Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Anti Mat Fabric Description:

Anti Mat Fabric is made of environmentally friendly raw materials, pp woven fabric. It used to prevent the growth of weed.

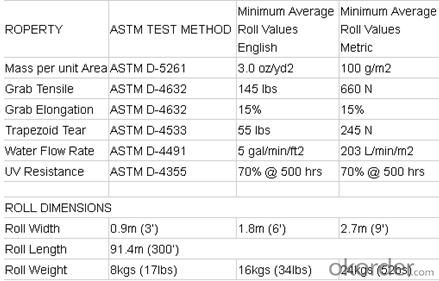

2. Anti Mat Fabric Specification:

3. Anti Mat Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

4. Anti Mat Fabric Property:

1) Light weight, high strength, low elongation, easy to construct.

2) Reinforcement, separation, drainage and filtration, fencing function, etc.

5. Anti Mat Fabric Application:

It can be widely used in areas of railways, highways, sport fields, earthwork, etc.

6. FAQ:

Q1:Can you send samples to us ?

A1:Yes , free samples could be provided , but customer need pay for the freight cost . After order placed , the freight charge could be refund .

Q2:What’s your Payment term ?

A2:T/T , L/C , Western Union,Paypal ...

Q3:What’s your manufacture process time ?

A3:Usually within 20 days

- Q: Can geotextiles be used in erosion control mats?

- Yes, geotextiles can be used in erosion control mats. Geotextiles are often used as a primary component in erosion control mats to prevent soil erosion by improving stability, drainage, and filtration.

- Q: Can geotextiles be used in underground gas storage projects?

- Yes, geotextiles can be used in underground gas storage projects. Geotextiles are often used as reinforcement materials to stabilize the soil and provide additional support for underground structures like gas storage facilities. They can help prevent soil erosion, control groundwater flow, and improve the overall stability and safety of the storage site.

- Q: What are the key factors affecting the durability of geotextiles?

- The key factors affecting the durability of geotextiles include the quality of the materials used, exposure to environmental conditions such as UV radiation and moisture, the level of mechanical stress and loading, and the installation and maintenance practices.

- Q: 200g geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How are geotextiles used in coastal engineering?

- Geotextiles are commonly used in coastal engineering to stabilize and protect coastal areas from erosion. They are deployed as a barrier along shorelines to prevent sediment migration, provide slope stabilization, and promote vegetation growth. Geotextiles also aid in the filtration and drainage of water, reducing wave energy and preventing scour.

- Q: Are geotextiles suitable for use in erosion control mats for revegetation?

- Yes, geotextiles are suitable for use in erosion control mats for revegetation. Geotextiles are designed to prevent soil erosion by stabilizing the soil and promoting vegetation growth. They provide a protective layer that allows water to pass through while retaining soil particles, which helps to reduce erosion. Additionally, geotextiles facilitate the establishment of vegetation by providing a favorable environment for root development. Overall, geotextiles are an effective solution for erosion control in revegetation projects.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines that need to be followed for geotextile installation in erosion control projects. Firstly, the geotextile must be placed on a properly prepared surface to ensure maximum effectiveness. The fabric should be tightly stretched and secured to prevent any movement or shifting. Additionally, the edges of the geotextile should overlap and be properly sealed to create a continuous barrier. It is also important to avoid any wrinkles or folds in the fabric as these can compromise its performance. Finally, regular inspection and maintenance should be conducted to ensure the geotextile remains intact and functional over time.

- Q: Are geotextiles environmentally friendly?

- Yes, geotextiles can be considered environmentally friendly. They are typically made from synthetic materials such as polyester or polypropylene, which are non-biodegradable. However, geotextiles offer various environmental benefits such as erosion control, soil stabilization, and water filtration. They help prevent soil erosion, reduce sedimentation in water bodies, and improve overall water quality. Additionally, geotextiles can be recycled and reused, further minimizing their environmental impact.

- Q: Basement roof cover soil thickness and geotextile shop in what position,

- The basement roof to do waterproof, covered with drainage board, and then laying in the drainage board geotextile, and then cover the geotextile 80 cm of soil. Huazhi geotextile material manufacturers

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. Geotextiles are permeable fabrics that can effectively filter out suspended particles, sediments, and pollutants from water. They are commonly used in various applications such as wastewater treatment, erosion control, and geotechnical engineering to improve water quality by removing contaminants through filtration.

Send your message to us

Geotextile Factory Woven Fabric Anti Mat Groundcover

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords