Woodpulp Laminated Spunlace Nonwoven Fabric, Wood Pulp Nonwoven

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

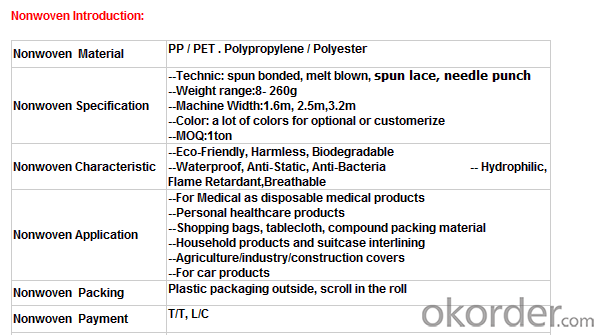

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Listed in recent years the textile industry pollutant emissions

- As the first half of the industrial added value increased by 13.2%, therefore, COD and sulfur dioxide and other major pollutants emissions are still increasing. Structural pollution is still outstanding. In the first half of the year, the COD emissions from the food processing industry, the paper and paper products industry, the chemical raw materials and chemical products manufacturing industry, the textile industry and the chemical fiber manufacturing industry increased by 67% and the growth rate Investigate 82.3% of the total COD emissions of enterprises;

- Q: Lin is what kind of textile

- 3, textile fiber classification: natural fiber and chemical fiber. ① natural fibers, including plant fiber, animal fiber and mineral fiber. A plant fiber such as: cotton, hemp, fruit fiber. B animal fibers such as: wool, hair free, silk

- Q: Differences between textile mills and garment factories

- After the carding, and lines, twisting, roving, spun yarn, winding, warping, weft, weaving, finishing and other long process made of gray cloth, and then sent to the printing and dyeing plant dyeing and finishing,

- Q: Is there a large yarn factory or a textile garment factory?

- Clothing (to fabrics, accessories all complete): cutting, film, sewing, ironing, inspection, packaging. The fastest 7 days out of the finished product. Above are theoretical calculations, and the actual difference

- Q: What is the meaning of the number of yarns used in cotton textiles?

- When the fibers are spun into yarn, they can be woven into a fabric. Because the weaving machine used in the principle of the machine is different, weaving the fabric of the internal structure is different. Usually can be divided into two categories of woven and knitted.

- Q: What is the whole process of textile and apparel trade?

- (1) The first is the main material, such as fabric varieties, yarn count, structure, weight, color (with particular attention to special colors, such as Ma gray); (2) accessories, including zippers ( Whether it is special, such as YKK), rope, buckle, eye, lace, elastic, woven cloth (should pay attention to whether the need for dyeing), horizontal machine rib, the main standard, water marked, tag, decorative cards.

- Q: What is the specialty of textile science and engineering?

- Textile science and engineering disciplines covering textile engineering, textile materials and textile design, textile chemistry and dyeing and finishing and other disciplines

- Q: What is the earliest textile tool?

- Spring and Autumn Warring States period has a greater improvement and development of looms. Jiangsu Sihong Cao Zhuang unearthed Han stone carved with "mother coffin diagram", the figure has oblique loom type. "Zhu Jing, carts" cloud "car carts, shaft of its empty" Zhu Xi "The Book of Songs" explained that "loom, weft wearers also, the axis of the people also" loops that shuttle, the axis is the main line axis

- Q: From the yarn to the finished textile fabric production process is how

- Including aliphatic PA, fat-aromatic PA and aromatic PA. Among them, the aliphatic PA varieties, large output, widely used, the name of the monomer by the specific number of carbon atoms

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Carpet rubber adhesive with the basic material for the ethylene and other olefinic monomer copolymer, such as ethylene - vinyl acetate copolymer, ethylene acrylate copolymer. The vast majority of cases are the use of ethylene. Vinyl acetate copolymer (EvA).

Send your message to us

Woodpulp Laminated Spunlace Nonwoven Fabric, Wood Pulp Nonwoven

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches