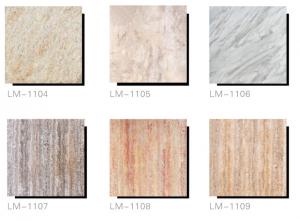

Wood Plastic Composite Tiles for different types

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Forestar WPC offers WPC decking with outstanding quality, best service and competitive price.

FORESTAR WPC DECKING TILES OF 300*300MM

FEATURES AND ADVANTAGES:

Outstanding Characters

• Dimension stability

It will not be out of shape after a long testing of 10 years and there is no crack under the test temperature between -40°c to 60°c

• Material Safety

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

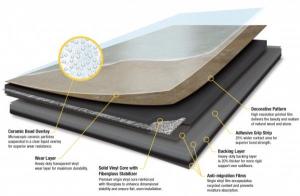

INGREDIENT Forestar WPC products are made of:

• 60% Bamboo/wood powder

• 28% Recycled HDPE/PP/PE/PVC powder

• 12% Chemical additives such as colorants, coupling agentsstabilizers, sreinforcing agents, foaming agents, lubricants, anti-UV agent, Anti-oxidation agent and anti fungus agent.

component of chemical additives may alter a little from different products adapting to different physical/ chemical demands.

FORESTAR'S BELIEF

In manufacturing products made entirely from waste plastics and waste wood, we have demonstrated our commitment to a number of crucial objectives.

• To ensure our products always exceed expectations of the purposes for which they are intended. To create products that are much more endurable than those made from conventional material.

• To constantly improve our technology to ensure the maximum amount of waste can be recycled.

• To minimize wastage in our manufacturing processes.

• To conserve precious natural resources.

• To provide customers the option of a new and update products, rather than something our previous customers asked for.

- Q: What are the reasons for the price rise of PVC plastic floor

- For example, PVC water pipes, PVC plastic doors and windows, as well as plastic toys containing PVC, wire and cable. Because of its harm to human body, Europe, Japan and South Korea and other countries have restrictions on using PVC as raw material and products. PVC resin has the advantages of plastic products is generally difficult to burn, abrasion resistance, chemical resistance, low leakage, good gas vapor

- Q: That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- What is your place to moisture, generally is the bathroom or kitchen room, water more places, do waterproofing, waterproofing a direct brush waterproof paint, do waterproof cloth, you may say is waterproof cloth, waterproof cloth she was first in the original ground brush cement slurry then, covered with waterproof cloth, waterproof cloth for bonding with the ground well, then brush on top of waterproof cloth in cement slurry, and tiling. That's no problem

- Q: Plastic foam flooring is not a large mosaic floor.

- You can put in a layer of foam on the floor quilt or blanket. This is safer. Foam floor dirty or a block of cleaning, more convenient.

- Q: Plastic floor to allow welding joints

- Hot welding: when the elastic floor is completed, the use of special material with the elastic floor material, according to the type of material to adjust the temperature of hot welding. The hot welding makes the two sides of the floor seam uniform

- Q: Thick floor leather household PVC floor paper waterproof plastic carpet anti-skid plastic floor glue how to install

- The material is of high wear-resistant floor rubber products, the main types of floor glue is too much, please choose the site of special products, if you are a family choose stone plastic sheet, choose the mall commercial airport pure material, rubber flooring, floor board special dance dance, rubber floor has a high requirement for the quality of the ground, the ground should be flat. No sand, dry ground, ground cracks, no different use requirements, main floor glue fire, anti-skid, environmental protection, easy to clean, variety, fast construction, long service life, our factory production of the special plastic Mio dance floor, if so we can provide samples for reference, to the membrane of different thickness different price you want, our dance floor (dance floor, many kinds of special).

- Q: Plastic foam on the floor there is no effect of moisture

- The plastic film under the wooden floor is called the ground mat, which can be used to play the role of moisture. Prevent moisture and moisture, so as to avoid the floor because of water seepage to the wood floor deformation. If there is no ground floor and the floor will be rubbing friction sound. There is also can play a role in the formation of the ground. Is an indispensable procedure.

- Q: The advantages of plastic floor tile

- Super slip: wear-resistant layer PVC plastic floor surface has a special anti-skid, and compared with common ground material, PVC floor (plastic floor) in the sticky water situations. More astringent, but not easy to slide into the water, which is more astringent. 6, fire retardant: PVC plastic floor fire index up to B1 level, B1 level that is very good fire performance, second only to stone. 7, waterproof: PVC plastic floor is the main component of vinyl resin, and water affinity, so its nature is not afraid of the water, as long as not long soak would not be damaged; and not because of high humidity and mildew

- Q: What is the material of the plastic foam plate

- Plastic foam floor: the name of the PVC plastic floor, the main material for the PVC resin. Commonly used into four categories, different types of additives are not the same

- Q: Is plastic floor glue toxic? Thank you

- Floor leather (toxic, mainly heavy metal exceed the standard): this kind of floor in black or dark bottom. Because of cheap, from 80s in China's mass production and application. Especially in the three northeastern provinces, a large number of people in the home are useful, with the promotion of commercial land in recent years, is now being reduced, and now the market is very environmentally friendly sales standards. Some are not under the environmental protection, but the surface is environmentally friendly, if there are children at home do not recommend the use of the more can not be used to artificial food mat

- Q: What are the main construction process of laying plastic floor

- Construction pointsGrassroots should reach the surface not sand, not skin, not grey, no hollowing, no grease. Touch without roughness. If the requirements are not met, the ground should be treated first.The positioning line pop-up perpendicular to each other, and according to the laying of parquet patterns.The back surface of the base plate and the plastic floor plate is coated at the same time, and the adhesive surface can be posted when the adhesive surface is not sticky.The bulk of each with a piece of, will more than rubber extrusion in a timely manner with clean cotton silk.Paving is completed, it is necessary to promptly clean the floor surface, the use of water-based adhesives can be wiped with a damp cloth, the use of solvent based adhesives, the use of turpentine or gasoline to wipe the gel marks

Send your message to us

Wood Plastic Composite Tiles for different types

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 PCS

- Supply Capability:

- 200000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords