Wood Plastic Composite WPC DIY Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Engineered Flooring

| Material | wpc floor tiles Eco-friendly wood plastic composite product. It is made of 60% wood fiber, 30%HDPE(Grade A Recycled HDPE) and 10% additives. |

| Size | 300mmx300mm,400mmx400mm,500mmx500mm |

| Design | wpc floor tiles |

| Color | Cedar, White, Red, Grey, Coffee, Maroon, Pine or as request |

| Certificate | ISO9001, ISO14001, CE, FSC, SGS, Intertek |

| Charateristics | 1. Looks and feels like natural wood; 2. 100% recycled, environmentally friendly; 3. Durable, Firm, High degree of UV and Color Stability; 4. Easy installation and low cost; 5. Weather resistant, suitable from 40-60. |

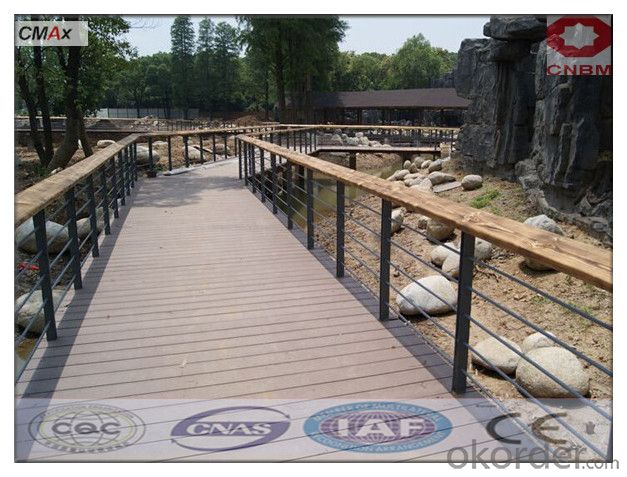

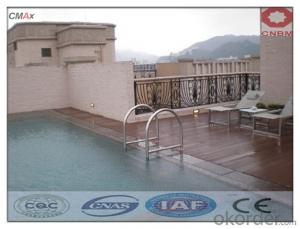

| Application | Swimming pool, garden, park, lawn,dock,balcony,playground, corridor |

Main Features of Engineered Flooring

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Engineered Flooring

FAQ of Engineered Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Such as title. Best to be detailed.

- At present, China's PVC flooring production is in a period of development, especially PVC sheet flooring (stone floor) production of domestic technology has been very mature, the country has a lot of well-known brands, production technology and quality are relatively high, many brands out Many foreign PVC floor manufacturers also set up factories in China, especially in South Korea, there are many manufacturers set up factories in China to produce. Some of the big brands of manufacturers will also own sheet flooring production line to China for production, and then sold back to the rest of the world. PVC flooring production technology alone is not yet mature, can only make a fake article, some key technology domestic floor manufacturers can only rely on imports, the product still has serious flaws, although there are foreign brands of manufacturers in China set up production , But the key technology is produced in foreign countries. If you want to introduce PVC flooring production line, I suggest you or the introduction of coil flooring production line as well. Because our country's PVC sheet flooring demand is very large, especially in the low-end PVC coil flooring market is very large. I am glad to answer the question of the landlord if any mistakes please forgive me

- Q: How long can a composite floor be used?

- Multi-layer parquet to the main home, the quality of the Japanese devils for the best, its wear resistance slightly worse, but the price is cheap, generally used for 10 years no problem, three solid wood flooring will be the future of the mainstream flooring , Its various indicators will be more than solid wood flooring, is now relatively high prices, the market acceptance is not high, in fact, this is the real good things

- Q: Whether the size of the composite floor 812 * 150 is standard

- Strengthen the floor This basically does not have a uniform size manufacturers in the production of the time according to their own circumstances and the country for the size of the general size of the provisions of many of the main focus on 1. Long 800 above the width of 120 or more 2.1200 above 160

- Q: What is the difference between the solid wood flooring and the flooring in the installation?

- Solid wood flooring installation in two ways: empty shop method, real shop method. Empty shop method of the higher cost, but the foot feeling comfortable, long life, and the ground is not demanding. The construction process of the empty shop method is to lay the dragon skeleton first, and leveling the ground, and then laying a layer of large core board, in the big board on the floor floor. Shaving method is the method of laying the floor directly on the ground. The construction process is simple, suitable for the ground condition is better, the duration of the project. Solid wood flooring use for a long time after the surface will be wear, can be re-polished, color, paint, the old as new. The installation of the composite floor is called suspension installation, that is, the floor is suspended above the ground. Pavement when the first leveling the ground, and then lay a layer of polyethylene foam pad, foam pad to play the role of tide and leveling, but also increase foot feeling. Floor shop on the foam pad, from the first three rows, should be dry and then continue to pave the skin, curing time of about 3 hours. The daily handling of the composite floor is very simple, just wipe with a semi-wet semi-dry mop. Composite floor of the surface is very wear-resistant, good quality composite floor life can be up to ten years.

- Q: i'm installing engineered hardwood click and lock flooring but absolutely none of the planks will click and lock with each other after one or two rows of planks have been set. ive been tapping them to put pressure, i've tried everything i could think of. please help

- You need to pitch the second piece and come in at an angle. head over to Home Depot or Lowes and have someone show you the correct angle. As a female I have done three different types of floors, the first was frustrating till the guy at home depot showed me the correct way.

- Q: How about solid wood flooring?

- Not bad, even the home of the security floor of the solid wood flooring, the quality of very good. Personal strong recommendation Oh!

- Q: Room shop to strengthen the composite wood flooring with a good board or a good board?

- First, depends on the style of home Second, look at the floor of the specifications, process recommendations: the room area to reach more than a dozen square, shop 1200 * 170mm effect of the chicken to squeeze the habit Less than ten square recommendations with small size, generally 810 * 130 / 150mm or so.

- Q: Home with wooden floor or tiles good?

- Tiles and flooring can be said to have their own strengths and weaknesses, each other pros and cons, if the economy can bear the words, or home with the elderly and children, it is best to shop solid wood flooring, warm, good foot feeling, but the price is high, Too troublesome. Followed by the whole pavement parquet, so warm and comfortable, care is also simple. But if more guests at home, the living room on the choice of floor tiles, bedroom selection of solid wood flooring, so relatively practical point. Floor tiles have a lot of benefits, environmental protection is better, usually take care of simple, but the warmth is not good, the winter will appear some cool, in fact, many good tiles prices are not low, plus pavement costs, the overall count down Must be cheaper than the floor. So it is recommended to use solid wood flooring.

- Q: Strengthen the composite floor environmental protection do

- Strengthen the composite floor formaldehyde content as long as meet the national standard, is the health and environmental protection of the floor. National standard E1-class products of formaldehyde emission limit of ≤ 1.5mg / L, the national development of the floor of the E-tail nail tube changed to a cool bucket of environmental protection standards, has taken into account the human health did not affect the factors, so as long as the choice Meet the environmental standards of the product is entirely possible. Some people think that the market has zero formaldehyde floor, in fact, this is a business slogan business only. There is no need to blindly pursue E0 standard products. And this misunderstanding of the formation of a large part of the reason is that many businesses caused "zero formaldehyde floor" gimmick. In fact, the so-called E0 standard products are not completely free of formaldehyde, EO grade formaldehyde emission products ≤ 0.5mg / L, but the lower formaldehyde release. In the purchase of reinforced composite flooring, let the business to produce quality testing report or smell the smell of wood floor, the general is a light wood aroma; and if there is pungent smell, it must not buy.

- Q: Multi-layer parquet, for geothermal, when the shop to shop moisture-proof pad? why? Do you want to play keel?

- Multilayer solid wood flooring installation whether to play keel, depending on their own circumstances. General multi-layer solid wood flooring playing keel, the foot feeling comfortable, more durable. But the cost of multi-layer solid wood flooring keel than other installation methods to be more expensive. First, the multi-layer solid wood flooring construction preparatory work: 1, the floor construction must be arranged at the end of all the decoration, in order to avoid other construction damage paint; 2, pavement floor must be dry, smooth; 3, Sprinkle a layer of mothproof powder. Second, the multi-layer solid wood flooring installation method: 1, straight paste method: like solid wood flooring installation, playing keel pavement; 2, straight shop method: the use of composite flooring method (that is, directly on the ground pavement); 3, high law: first on the ground covered with 62.5px thick pavement treasure. And then shop the moisture pad, and finally covered with multi-layer solid wood flooring.

Send your message to us

Wood Plastic Composite WPC DIY Decking Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords