wood plastic composite deck board wpc decking for balcony and garden

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Packaging & Delivery

| Packaging Detail: | Packed with pallet. |

| Delivery Detail: | Within 2 weeks got the deposit. |

Specifications

wpc decking

1.Place of Origin: CN; ZHE;

2.Features: Waterproof,Fireproof;

3.Application:park,garden.

4.Certificate: ISO 9001

Product Description

2014 New Outdoor 146x24mm WPC Decking Prices For Public

Wood plastic composite(WPC)made of 50% wood fiber and 50% PP,PE or PVC resin together with specialized ingredients, imported pigment, and anti-UV material. WPC products possess the advantages of good intensity, high rigidity, durable usage period, moisture proof, anti-abrasion, heat insulation, fire-resistant, aging-resistant, cauterization-resistant, water proof, insect resistant, and no painting needed. WPC products can be widely used in public garden or park, construction decoration, villa garden and so on.

Features:

(1) Insect-proof

(2) Durable, economic.

(3) Cost low in maintenance.

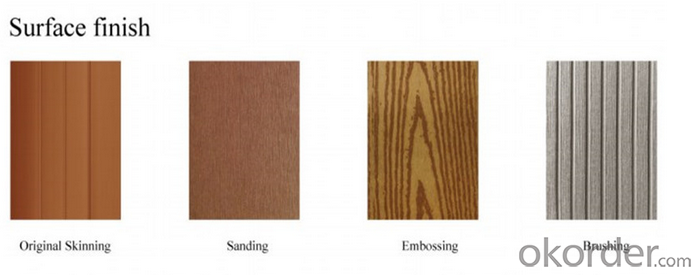

(4) Brand range of appearance and color.

(5) Environmentally friendly, recyclable.

(6) Looks and feels like nature wood.

(7) Easily and conveniently installed and cleaned.

(8)Stable over a wide temperature range, weather resistant,especially can be used in the open air.

Technical Index:

| Techinical Index | |||

| No. | Property | Result | Text Method |

| 1 | Density | 1.23g/cm | ASTMD792 |

| 2 | Water absorption | 0.50% | ASTMD570-00 |

| 3 | Tensile strength | 14.2Mpa | ASTMD638-03 |

| 4 | Elongation Rate at break | 3.90% | ASTMD638-03 |

| 5 | Flexural strength | 30.0Mpa | ASTMD790-03 |

| 6 | Flexural modulous | 3500Mpa | ASTMD790-03 |

| 7 | Linear expansibility | 4.9×10—5°C-1 | ASTMD696-03 |

| 8 | Compress strength | 26.4 | ASTM695-02 |

| 9 | Impact streght(unnotched)-25°C—+30°C | 90.1 J/m | ASTMD256-03 |

FAQ:

(1) what is WPC ?

SGB WPC is a green buidling material, it's made of 60%-65% natural wood fiber( Professionally Dry treatment ) ,30%-35% of eco-friendly HDPE materials and 5% -10% Chemical additivel ( anti-UV agent, anti-oxidation agent, reinforcing agent, stabilizers, colorrants, anti-fungus agent, coupling agent ect..).

(2) How long is the service life of WPC product ?

15-20yeras.

(3) What the weather temperature is suitable to use our WPC products ?

It's from -40°c to 60°c.

(4) Do WPC product need the good ventilation and drainage ?

Yes, like timber, it's important to provide adequate ventilation and drainage to ensure SGB WPC is able to dry out after being wet. For this reason, it's very important to pay attention to clearance on butt joins ( end to end), spacing between boards( side to side), and min. ground clearance. Lack of ventilation and drainage can cause the products to swell over time. Check product fix informations on the good ventilation and drainage requirements. Boxing in the deck will reduce cross flow ventilation and therefore should be avoided.

- Q:New home decoration! For the floor is not very understand!

- Environmental protection is certainly solid wood is good, the cost of materials are also tattoo dung on the pedal irony is a solid wood is good but the composite floor also has its advantages, such as can be made scratch-resistant, and solid wood flooring is more need to carefully maintenance

- Q:Such as how the ground needs to pave the way, and so on? Why some say that some say no more

- I am going to sell composite flooring below the floor to be sure to install is sure to shop a layer of moisture-proof pad of course if you are living room tile tiles bedroom according to the floor because of the tiles of high-chihuan cough yinjiao turtles melon film floor so if you are willing Usually in the shop a pavement treasure that is the level of balance that thing you choose the price is not the same general does not exceed 10 fast a square (do not let the floor in this thing to make money on you) other basic do not need to It is also a snake Tim to make money in order to make you get there that upstairs that kind of situation do not have to worry about the quality of the house is now poor cement floor 90% uneven (our own practice data ah) as long as not too serious basic nothing will not There is a sound just started when stepping on a little soft but after all, the composite floor is still more tough to install a good step on the basic step on nothing

- Q:Composite flooring installation requires tools,

- Wooden floor installation requires the following tools: Power tools: hammer, pistol drill, marble sawing machine, curve saws, steam pump, steam gun, electric planer, mill, belt sander. Hand tools: hand saws, knife saws, fountains, steel tape, angle ruler, pencil, pull rope, hammer, ax, rubber hammer, punch, scraper, screwdriver, pliers, flat chisel, planing, Special tools: move the hook, tighten the hook. Wood flooring installation process should pay attention to: 1, wood flooring can not buy that shop, should be opened in the new home after a period of time and then shop, so that the wooden floor to adapt to the new environment. 2, do not think that the wood floor can not contain water, in fact, left the water, the wood floor becomes very hard, at the foot of the feeling is not the same, so to keep the wood floor water content of about 14%, of course, this is a professional tool inspection of. 3, wood grille and the ground between the grass-roots should retain a certain gap (primary school textbooks to teach us, to know how to stay a seam), to ensure that the entire ground dragon air patency, do not use cement mortar plug to fix the wood grid In order to use the mattress method, the wooden grille shall be firmly fixed to the ground with nails. 4, shop wood flooring should be cleaned before the wooden grille, sprinkle with moisture-proof powder and pest control powder. This is to prevent insects from eroding the wood flooring material and destroying the structure of the wood floor. 5, nail wood floor nails must use twist nails, first in the mouth of the mouth oblique drilling (holes should be perpendicular to the length of the floor), and then into the wooden grille, or the use of the process is likely to cause loose wood flooring. 6, after the laying of wood flooring to use cardboard, old sheets or old mats and other cover protection. The purpose of this is to protect the original installation of the wood floor structure, firm its structure.

- Q:i'm installing engineered hardwood click and lock flooring but absolutely none of the planks will click and lock with each other after one or two rows of planks have been set. ive been tapping them to put pressure, i've tried everything i could think of. please help

- You need to pitch the second piece and come in at an angle. head over to Home Depot or Lowes and have someone show you the correct angle. As a female I have done three different types of floors, the first was frustrating till the guy at home depot showed me the correct way.

- Q:Will the composite floor be faded for a long time?

- Composite flooring is more durable than the average wooden floor, unless the long period of light exposure will not discolored it

- Q:Solid wood composite floor to buy what to pay attention to

- 1. As with solid wood flooring, solid wood flooring is also divided into excellent, first class, qualified three categories. Appearance quality is an important basis for grading. 2. There are two kinds of solid wood flooring, one for the three solid wood flooring, which produced earlier, by the panel, core board, backplane three layers of wood together. 3. Consumers in the purchase, through the multi-layer solid wood floor of the four sides of the tenon, you can see the body of the crown of the liver and the Philippines to the veneer layer of superstructure. 4. Paint quality and coating method is to determine the floor environmental protection, wear resistance, hardness and other parameters of the important factors 5. Multi-layer solid wood flooring by a number of wood board assembled from bonding, the quality of the floor adhesive, environmental performance It is important. 6. Get the floor, you can in a box in the hand to take more than 5 floors placed on the glass table or flat on the ground, to assemble. 7. Solid wood flooring laying methods are many, no matter what kind of laying method should be standardized. And the best is who to sell who installed, to avoid unnecessary buck and trouble. More detailed related content can go to the only excellent network of the only excellent college to see, hope to be useful to you

- Q:Just installed a composite floor, because the brush of the porcelain led to a lot of gray floor, wiped many times are difficult to clean, how should I do? More

- Strengthen the maintenance of wood flooring as follows: 1) after the laying of the floor is completed, we must always keep the flow of indoor air. 2) heavy items should be placed smoothly, furniture and heavy objects can not be hard to push and pull drag, so as not to scratch the surface of wear-resistant layer. 3) can not scratch with a weapon, plan the floor surface. 4) Do not use water in the water soak the floor, if any accident, should be dry with dry towel dry the floor. 5) to keep the floor dry and clean, the surface of the floor if there is dirt, generally do not drip with a tidal wipe dry. 6) to prevent the floor by the cooker baked and deformation. 7) should be placed in front of a rub foot pad to reduce the sand on the floor wear. 8) Remove spots and stains with floor cleaning agents. Do not use damaged items, such as metal tools, nylon friction pads and bleaching powder.

- Q:How to install the composite flooring is installed? Is the installation of good-looking? Question added: but how is the pin line fixed in the corner?

- Floor manufacturers responsible for the installation of your supervision on the line

- Q:New house, composite floor scratches have been very obvious, all fine lines, is the floor of the problem? More

- This may be pavement in the process of friction caused by a small scratch on the simple wax on the line to study the trouble

- Q:Mianqi composite floor drum up how to do?

- Less than two months after the floor pavement drum up, this is the installation of quality problems. Should be in accordance with the floor of the relevant provisions of the sales, requiring businessmen to send people to the scene. In general, if only improperly installed, too close, leaving the gap is small, you can open, and then re-pavement on the line. But if the composite floor of the original adhesive layer stratification, it is the quality of the floor, they should replace the floor. And, once such a problem occurs, it is best to return. Because, this quality of the quality of the floor is poor, there will be problems later. If your house is on the ground floor, it may be caused by too much moisture on the ground. But if this is the case, the factory workers should be told when you carry out the inspection before installation. If not, it is their approval to meet the pavement conditions, the responsibility is still their. I said these, it is estimated. Or should be sent to the scene after the business to determine. I hope my answer will help you. And then add: If you are not a regular business to buy or other reasons can not be repaired by them. So, after removing the wet cause, it can only be improperly installed. That is, when the pavement did not leave enough expansion of the gap. The repair method is: you can remove the already bulging part, and then re-install one by one, to the wall, the excess part of the cut, and keep the floor and the wall has 10-15mm gap, the gap can Through the installation of the baseboard and cleverly covered.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

wood plastic composite deck board wpc decking for balcony and garden

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products