Plastic Sheets - White Cheap PVC Foam Board 4x8 for India Market 0.53 Density PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Specifications:

Product Name | PVC/WPC foam sheet |

Size | 1220mmX2440mm; Customized |

Thickness | 4~25mm |

Density | 0.5~0.9g/cm3 |

Color | White,Yellow, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

Certificate | ISO9001 CE |

Weldable | Yes |

Foam Process | Celuka |

Water saturation | <1%< span=""> |

Tensile strength | 12~20MPa |

Elongation at break | 15~20% |

Vicat softening point | 73~76 °C |

Impact strength | 8~15KJ/m2 |

Shore Hardness | D 75 |

Flexural modulus of elasticity | 800~900MPa |

Bending strength | 12~18MPa |

Life Span | >50 years |

Flame retardance | self-extinguishing less than 5 seconds |

Production Introduction:

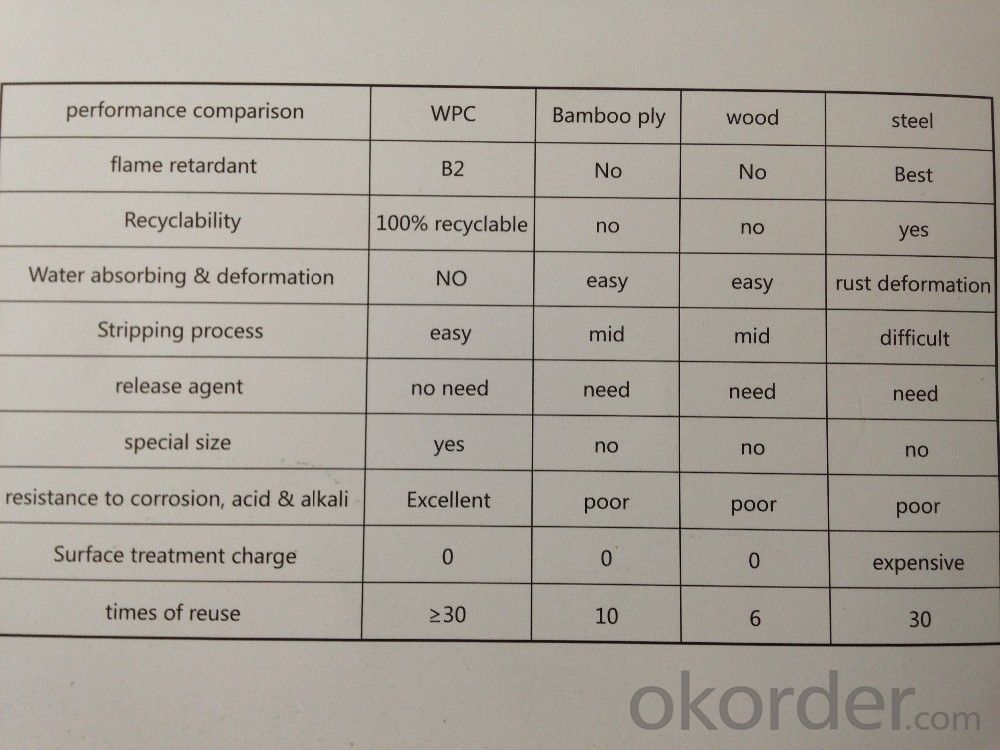

* Hygienic, rigidity, durable; Recycle

* Light weight, easy and convenient to storage, transportation and use

* lead-free, acid-free and non-toxic

* Fire retardant and self extinguishing

* Wide variety of application;It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc.

* Perfect chemical corrosion resistance, good resistance to UV & weathering

* Moisture-resistant, mildew proof, rot proof, low water absorption;Will not rot and mold,Impervious to moisture, insects, salts

* Sound insulation, sound absorption, heat insulation and heat preservation

* Easily to put protective film on one or two sides

* Virtually maintenance free

--PVC Celuka Foam Board

No formaldehyde;

Strong and durable;

Lightweight and easy to install;

Will not rot,warp,delaminate,cup or twist;

Resistant to weathering,shock and abrasion;

Slat water corrosion resistant;

Impervious to salts,insects and many chemicals;

including some acids;

Doesn't mold;

Can be worked just like wood;

Non-toxic;

100% recyclable;

Fire-retardant(self-extinguishing);

Easy to clean;

Virtually maintenance free;

--WPC Celuka Foam Board

Low water absorption;

Fire Retardant;

Resistant to chemical&corrosion;

Easy to work;

Good sound insulation;

Weather resistant;

Good thermal insulation;

Very low weight;

Smooth and Glossy surface;

Suitable for both indoor &outdoor application;

Suitable for film lamination;

Thermoforming;

Non-toxic

Fine celled foam structure.

Product Application:

--Construction (wall panel,ceilings,decoration etc.;

--Cupboard(Kitchen &Bathroom)

--Furniture Board;

--Automobile floor,icebox,raft cabin;

--Advertising and Carve;

--Marine(seating,covers,shelving ,cabinets,stairs,electronics&

wall panels,door and more);

--Water park;

--Seashore wet-proof facility;

--Various interlayer;

--Decoration board,upholstery,mould plate for train,car and many more.

Install instruction and notice:

1) can put it anywhere when install it

2)easy to nail, drill, nail and cut to any size you want

3)the keel or supporter should be flat, the maximum distance is 240mm between to keels or supporters

4)enhance iron nail, about 10mm to board edge to nail.

5)when form removal, don't be violent.

6)when repeat to use it, don't need to brush parting agent

Color

Green, black, blue, dark red, yellow, flower gray etc.

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: Would you please tell me the company have business relations which countries?

A: Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places.

Q: If the products have some quality problem ,how will you deal with it?

A: 1,If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

2,Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Packing picture

Product pictures

- Q: Are plastic sheets resistant to deformation under load?

- Yes, plastic sheets are generally resistant to deformation under load. However, the level of resistance may vary depending on the type and thickness of the plastic sheet.

- Q: How do plastic sheets compare to glass or acrylic?

- Plastic sheets, such as polycarbonate or PVC, offer several advantages over glass or acrylic. Firstly, they are much more durable and resistant to impact, making them ideal for outdoor or high-traffic areas. Plastic sheets are also lighter in weight, making them easier to handle and install. Additionally, plastic sheets are more cost-effective compared to glass or acrylic. However, glass and acrylic have better optical clarity and scratch resistance, making them suitable for applications where aesthetics and visibility are crucial. Ultimately, the choice between plastic sheets, glass, or acrylic depends on the specific requirements and priorities of the project.

- Q: Are plastic sheets resistant to fading from sunlight?

- Yes, plastic sheets are generally resistant to fading from sunlight.

- Q: Is there a glue that can seal/bond 2 thin (about 30 microns or less) sheets of plastic together, the same EXACT way that they would seal/bond if the same 2 sheets were heat sealed? (kinda like those food vacuum sealers)

- It depends on the following: Your definition of EXACT....heat seal actually remelts the plastics in the area of the seal making it as if it were one continuous piece For some plastics, like PVC, you can solvent bond two pieces together, where basically a very powerful solvent dissolves the immediate area of the two pieces and they are bonded when the solvent evaporates It will very substantially from plastic to plastic. If by EXACT you mean the same physical properties, there are specialty adhesives that may meet that requirement...again it varies substantially from plastic to plastic

- Q: as thick as ,5mm to 1.2mmdon't say try google or something stupid like that(a webstore please)

- You should try Home Depot or Lowes

- Q: Are plastic sheets resistant to staining?

- Yes, plastic sheets are generally resistant to staining due to their non-porous nature and smooth surface, which makes them easy to clean and maintain.

- Q: can you stitch cross stitching patterns on plastic canvas sheets?

- Yes, as long as the design uses only full stitches. 1/4 1/2 stitches will give you problems. Size is another issue, the smallest plastic canvas is 14 count. So you won't be able to do designs that are larger than the actual size of the sheet.

- Q: Is the resin scraping board made of plastic?

- Resin is the main raw materials for the manufacture of plastics, paint is also used the system (the main film-forming material, coating such as alkyd resin, acrylic resin, synthetic fatty acid resin, the resin in the Yangtze River Delta and Pearl River Delta are also relatively strong in the paint industry, such as Changxin chemical, Nuplex resin, three resin, Ying DSM syntech resins), adhesives, insulating material, synthetic resin in industrial production, is widely used in separation and purification of impurities in liquid, with macroporous adsorption resin, ion exchange resin, and some special resin.

- Q: I had a pilonidal cyst removed from my natal cleft (aka butt crack) last Tuesday, and to reduce the risk of infection, the surgeon used surgical glue to close the wound's exterior, and a sheet of super-sticky surgical plastic to keep my cheeks together and provide another layer of protection from infection.Well, it started peeling up a bit at the top and bottom and letting some air get to the would, so I peeled off a little bit and trimmed it off (with help, lol). I went as far as I dared to, but I just hit a part where it hurt. I'm concerned about infection getting to the spots where air had already made it in, but I also don't want to open the wound.I don't have an appointment with my surgeon until Thursday- do you think it would be okay to wait for him to remove it, or should I just use some Vaseline to take the rest of it off now?

- wait until you see the surgeon. Let him remove the bandage. If you are concerned with the tape coming off and air getting in, call his office and talk to the nurse. She will advise you on what to do.

- Q: I got, what I thought was a great deal on photo albums. When I got them home, I discovered they are only plastic envelope type pages. After reading the covers on the albums, it says clearly says sheet protectors, so what do I need to purchase to stick my pictures on to put into these plastic sheets?I am new at scrapbooking and photo album placements!!!!

- Yes, if the work is still copyrighted (they eventually expire) then the copyright owners have the exclusive right to make copies or derivative works (transcribing it into other forms), as well as distribution or public performances, subject to certain limitations. One of those limitations is called fair use, often involving private use without any commercial gain or private profit. The mere photocopying is technically illegal, as it simply displaces the copy you SHOULD have purchased from the authorized distributors. Someone already mentioned one other exemption that involves educational use in a classroom of a non-profit school, provided the other limitations are met. Even if you go to a public library, there must be signs on the photocopy machines that instruct you about the basics of copyright law and remind you that not all copying is allowed. As for including the composer and copyright, that is common courtesy, but also insufficient to demonstrate that you have the necessary license. You could, in theory, be sued if you were to distribute photocopies of the sheet music (even for free), but there is typically little chance of anyone doing that to you for a single instance. If you take it to a retail print shop and have them run off a hundred copies, you would both be guilty of a federal felony, since they are taking money for willful infringement. Bottom line: yes, it's illegal in most cases; however, you are unlikely to be sued for one or two copies.

Send your message to us

Plastic Sheets - White Cheap PVC Foam Board 4x8 for India Market 0.53 Density PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords