Waterproofing EPDM Pond Liner for Garden/Lake/Pond Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Technical Sheet:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

4. Features:

1. Waterproofing EPDM pond liner has excellent resistance to environmental stress cracking resistance, aging resistance, corrosion resistance as well as long service life.

2.Waterproofing EPDM pond liner has the lowest permeability

3. Waterproofing EPDM pond liner has high elongation,heat treatment the size change is small

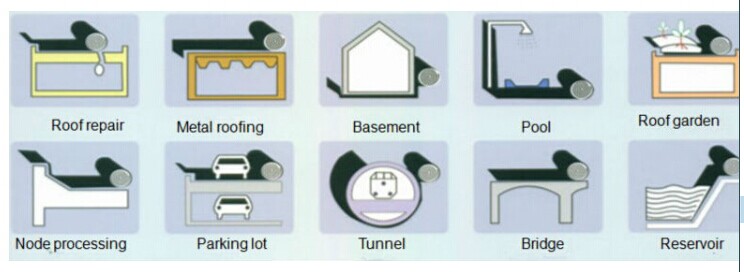

5. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

5. Some photos:

- Q: Can a waterproofing membrane be used for above-grade applications?

- Indeed, above-grade applications can benefit from the use of a waterproofing membrane. In construction, waterproofing membranes are widely employed to safeguard structures against water infiltration and subsequent harm. While they are commonly utilized for below-grade purposes like basements and foundations, waterproofing membranes can also be applied above-grade on surfaces such as roofs, decks, and exterior walls. When utilized above-grade, waterproofing membranes serve as an effective moisture barrier, preventing water from permeating the structure. These membranes are specifically designed to endure prolonged exposure to various elements, including rain, snow, and UV rays. By effectively sealing the surface, a waterproofing membrane aids in shielding the structure from water damage, mold growth, and deterioration. Several types of waterproofing membranes are available for above-grade applications, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are typically constructed from materials such as modified bitumen, polyurethane, or rubberized asphalt, which possess exceptional waterproofing properties. Proper surface preparation is crucial when installing a waterproofing membrane above-grade. The surface must be thoroughly cleansed, completely dry, and devoid of any substances that might undermine the membrane's adhesion. Additionally, it is vital to adhere to the manufacturer's instructions and guidelines regarding application techniques and recommended thickness. In conclusion, a waterproofing membrane can effectively shield structures from water infiltration and damage when used in above-grade applications. By selecting the appropriate membrane type and adhering to proper installation procedures, a durable and dependable waterproofing system can be established for above-grade surfaces.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some of the essential tools and equipment include: 1. Protective gear: This includes gloves, goggles, and a face mask to protect yourself from any harmful chemicals or fumes. 2. Cleaning equipment: Before installing the membrane, the surface needs to be clean and free from any dust, debris, or loose particles. Therefore, you may need a broom, vacuum cleaner, or pressure washer to clean the area properly. 3. Waterproofing membrane: The specific type of membrane will depend on the project requirements, but it is essential to have the appropriate membrane material and enough coverage to ensure a proper seal. 4. Primer: In some cases, a primer may be needed to enhance adhesion between the surface and the membrane. The primer type will depend on the surface material and the membrane being used. 5. Application tools: These tools are used to apply the membrane onto the surface. Common tools include brushes, rollers, or sprayers. The choice will depend on the type of membrane and the size of the project. 6. Seam tape: If the waterproofing membrane requires seams, a seam tape will be needed to ensure a watertight seal at the joints. The tape should be compatible with the membrane material. 7. Adhesive or adhesive tape: Some waterproofing membranes require an adhesive to bond them to the surface. Alternatively, adhesive tape can be used for self-adhesive membranes. 8. Cutting tools: Depending on the shape and size of the area to be waterproofed, you may need cutting tools such as utility knives or scissors to trim the membrane to the desired size and shape. 9. Caulking gun: A caulking gun is necessary for applying sealant or caulk to fill any gaps or cracks in the surface before installing the membrane. 10. Drying equipment: After the membrane is installed, it may require a certain amount of time to dry or cure. Fans or dehumidifiers may be needed to accelerate the drying process, depending on the specific membrane and environmental conditions. It is important to consult the manufacturer's guidelines or seek professional advice to ensure you have all the necessary tools and equipment for a successful installation of the waterproofing membrane.

- Q: Can a waterproofing membrane be used in boat decks or marinas?

- Yes, a waterproofing membrane can be used in boat decks or marinas. It is commonly used to protect the underlying structure from water damage and provide a durable, watertight barrier that helps prevent leaks and deterioration.

- Q: Can a waterproofing membrane be used on concrete block walls?

- Concrete block walls are prone to water infiltration, which can cause problems like mold, mildew, and structural harm. To combat this, a waterproofing membrane can be utilized on the walls. This membrane acts as a protective shield, applied to the surface of the concrete blocks, effectively stopping water from seeping in. By creating a moisture-resistant barrier, it establishes a tight seal, preventing water from entering the interior of the walls. This aids in preserving the walls' integrity and safeguards against water-related damage. However, it is crucial to ensure that the waterproofing membrane is correctly installed and that any existing cracks or gaps in the concrete block walls are adequately sealed before its application.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Indeed, masonry surfaces can benefit from the utilization of a waterproofing membrane. Employing a waterproofing membrane on masonry surfaces is a prevalent approach to thwart water infiltration and subsequent harm. Concrete, brick, or stone masonry surfaces are permeable and have the capacity to absorb water, resulting in potential structural deterioration, growth of mold, and overall degradation over time. The purpose of a waterproofing membrane is to serve as a barrier, preventing water from permeating the masonry and safeguarding it against moisture-related predicaments. It is crucial to select a waterproofing membrane that is specifically engineered for masonry surfaces and adhere to the instructions provided by the manufacturer for appropriate application.

- Q: Can a waterproofing membrane be used in combination with insulation materials?

- Yes, a waterproofing membrane can be used in combination with insulation materials. In fact, it is often recommended to use a waterproofing membrane in conjunction with insulation to provide enhanced protection against water damage and moisture intrusion. The waterproofing membrane acts as a barrier, preventing water from penetrating the building envelope, while the insulation materials help to regulate temperature and improve energy efficiency. By combining these two elements, you can create a more durable and efficient building envelope system. However, it is important to ensure that the chosen waterproofing membrane is compatible with the insulation materials being used, and that proper installation techniques are followed to ensure a tight seal and optimal performance.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Yes, a waterproofing membrane can be used in crawlspaces or basements. In fact, it is highly recommended to use waterproofing membranes in these areas to prevent moisture infiltration and water damage. Crawlspaces and basements are prone to water seepage and high humidity levels, which can lead to mold growth, structural issues, and damage to stored items. A waterproofing membrane acts as a barrier against water intrusion by effectively sealing the foundation walls and floor. It creates a watertight seal that prevents water from seeping into the space, keeping it dry and protected. Additionally, waterproofing membranes also help to control moisture levels by reducing condensation and humidity, thereby creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is an essential measure to ensure the longevity and integrity of the structure and to safeguard against potential water-related problems.

- Q: How does a waterproofing membrane adhere to a surface?

- A waterproofing membrane adheres to a surface through a combination of mechanical and chemical bonding. The process typically involves the application of an adhesive or bonding agent to create a strong and durable connection between the membrane and the surface it is being applied to. Mechanical bonding occurs when the membrane is physically held in place by the irregularities and imperfections on the surface. This can be further enhanced through the use of mechanical fasteners such as screws or nails, which help secure the membrane in place. These mechanical bonds provide initial stability and prevent the membrane from shifting or peeling off. Chemical bonding, on the other hand, involves the use of adhesive materials specifically designed for waterproofing applications. These adhesives are typically applied to the surface and the backside of the membrane. Once the membrane is pressed onto the surface, the adhesive chemically reacts with the surface and the membrane, creating a strong bond. The effectiveness of the adhesive is influenced by factors such as surface preparation, environmental conditions, and the type of membrane and adhesive being used. Proper surface preparation, which may involve cleaning, priming, or leveling the surface, ensures that there are no contaminants or unevenness that could compromise the bond. In summary, a waterproofing membrane adheres to a surface through a combination of mechanical and chemical bonding. The mechanical bonds provide initial stability, while the adhesive materials create a durable and long-lasting connection between the membrane and the surface.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Yes, a waterproofing membrane can be used on below-grade walls to prevent water infiltration and moisture damage.

- Q: Are waterproofing membranes resistant to ponding water?

- Yes, waterproofing membranes are generally resistant to ponding water. Waterproofing membranes are designed to create a barrier that prevents water from seeping through and causing damage to the underlying structure. This includes standing or ponding water that may accumulate on the surface. However, it is important to note that the effectiveness of waterproofing membranes can vary depending on the specific product and installation technique used. It is recommended to consult with a professional to ensure the correct membrane is selected and installed properly to provide the desired level of resistance to ponding water.

Send your message to us

Waterproofing EPDM Pond Liner for Garden/Lake/Pond Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords