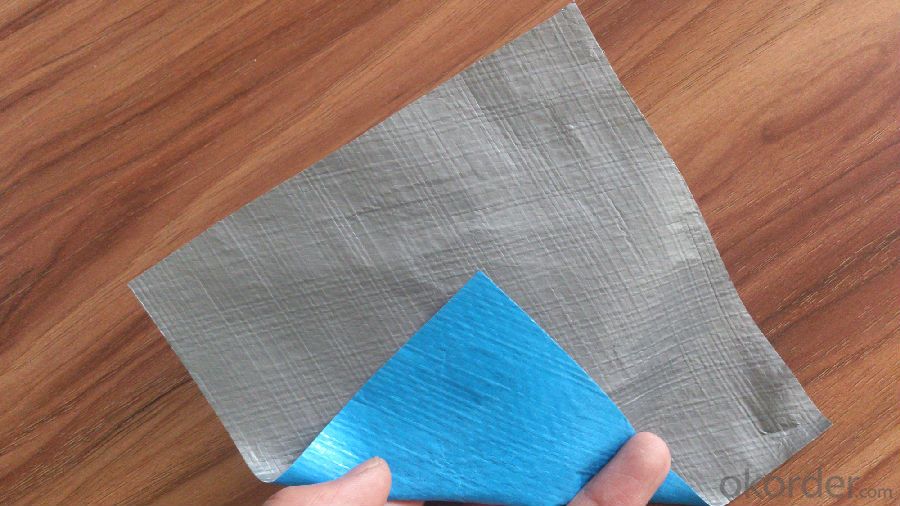

Waterproof PE Tarpaulin 70-200G Blue Color

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PE Tarpaulin:

PE fabric both sides laminated, reinforced by PP rope in hem on all around edges. Aluminum eyelets every 1 meter or 3’ or 1yd interval (30cm, 50cm interval also available).

Specification of PE Tarpaulin:

Weight: 70g/m2-300g/m2

Density / sq. inch :7*6, 7*7, 8*7, 8*8, 10*8, 10*10, 12*12, 14*14, 16*16

Color: Any color available

Size: 2*3m, 3*4m, 4*6m….. any size available

Denier: 750-3000 Denier

UV. FR treatment also available

PE fabric both sides laminated, reinforced by PP rope in hem on all around edges. Aluminum eyelets every 1 meter or 3’ or 1yd interval (30cm, 50cm interval also available).

Application of PE Tarpaulin

PE Tarpaulin can be widely used in as the cover as well as other usage. It can be used in industrial, agricultural, garden and home.

Industrial: Covers for general use, scaffoldings in construction sites, underground sheets,

Covers for truck, cars, boats, containers, warning tapes,

Covers for materials, roofs, road repair sites, fences

Agricultural: Covers for timber, hay, cotton and all kinds of crops

Covers for daring crops

Home/Garden use: Covers for garden, backyard use

Covers for furniture

Gazebo tentd, dining canopies, swimming pool covers

Packing of PE Tarpaulin

1. For rolls , packed in a plastic bag with a label between rolls and bag

2. For Tarpaulin sheets, Each piece in a polybag with a label then proper pieces in a carton box packing or same color bale packing

Picture of PE Tarpaulin

- Q: Plastic molding is what to do, how the process?

- The process is divided into four phases:The first stage, plastic injection. When the melt enters the mold cavity, it meets a lower temperature mold wall, forming a thinner solidification layer;The second stage: gas incidence. The inert gas enters the molten plastic, pushing the center of the uncured plastic into the cavity that is not yet filled;The third stage: gas incidence. The gas continues to flow through the plastic melt until the melt fills the mold cavity;The fourth stage: gas pressure maintaining. Under the condition of holding pressure, the air in the air compresses the melt to supplement the material to ensure the appearance quality of the parts.

- Q: How many grades are there in the plastic block? How to divide?

- Flame retardant grade bottom HB:UL94 CSA and C22.2 No 0.17 standard, requirements for 3 to 13 mm thick sample, the burning rate is less than 40 mm per minute; less than 3 mm thick sample, the burning rate is less than 70 mm per minute; or extinguished in 100 mm signs before.V-2: the flame was extinguished in 60 seconds after the two and 10 second combustion test of the sample. A fire can fall off.V-1: the flame was extinguished in 60 seconds after the two and 10 second combustion test of the sample. No fire can fall.V-0: the flame was extinguished in 30 seconds after the two and 10 second combustion test of the sample. No fire can fall.

- Q: Do olive nets affect the nutritional value of the olives?

- No, olive nets do not affect the nutritional value of the olives.

- Q: The use of various plastic materials

- GPPS modified polystyrene 204The transparency of 88-92%, refractive index 1.59-1.60, suitable for light products, dyeing is strong, non-toxic and tasteless, no fungus growth, high impact strength, resistance to acid and alkali resistant performance is good, not on the basis of solvent, excellent electrical properties, easy molding, moisture less than 0.02% can maintain the strength and size of high humidity, but the brittleness.Suitable plastic products: decorations, lighting signs, lampshades, stationery, transparent toys, daily necessities, instrument lenses, freezers and thermal insulation in the refrigerator (after foaming).

- Q: How does an olive net affect the overall pest management in the olive grove?

- An olive net can significantly improve pest management in an olive grove. By covering the trees, it acts as a physical barrier that prevents pests like insects, birds, and rodents from accessing the fruits. This helps to reduce damage caused by pests, such as feeding on the olives or spreading diseases. Additionally, the netting also reduces the need for chemical pesticides, as it minimizes the pest pressure on the trees. Therefore, an olive net contributes to a more sustainable and effective pest management approach in the olive grove.

- Q: Can a plastic water cup be boiled in general?

- There are Tupperware color series of water glass is a color, which shows that in the process of plastic is added to the color masterbatch, it is recommended that the cup as little as possible.In view of the above, buy a plastic cup to buy colorless, can not be hot water use.

- Q: How do olive nets facilitate the collection of fallen olives?

- Olive nets facilitate the collection of fallen olives by providing a protective barrier between the olives and the ground. These nets are spread under the olive trees, creating a catchment area that prevents the olives from scattering or getting dirty. When the olives fall from the trees, they are safely caught by the nets, making it easier to gather them in large quantities. The nets also prevent damage to the olives, as they avoid direct contact with the hard ground, ensuring the quality of the harvested fruit.

- Q: How do olive nets affect the air circulation around olive trees?

- Olive nets can impede air circulation around olive trees. When draped over the trees to protect the olives from birds or insects, they create a physical barrier that restricts the flow of air. This can lead to increased humidity and reduced ventilation, which may create a favorable environment for fungal diseases. Additionally, restricted air circulation can hinder pollination, as it limits the movement of pollen between flowers.

- Q: Thinner can clean plastic products?

- If it is a small number of mobile phone plastic shell, you can use eraser to clean; batch can use professional plastic cleaning agent, etc..

- Q: Can olive nets be used in combination with soil erosion prevention techniques?

- Yes, olive nets can be used in combination with soil erosion prevention techniques. Olive nets are commonly used to protect olive trees from pests, but they can also be effective in preventing soil erosion. By installing olive nets on slopes or areas prone to erosion, they can help to stabilize the soil and prevent it from being washed away by rainwater or blown away by wind. Additionally, the nets can also provide shade and reduce evaporation, promoting moisture retention in the soil and further preventing erosion. Therefore, using olive nets in combination with other erosion prevention techniques such as terracing, mulching, or planting ground cover can enhance the overall effectiveness of soil erosion prevention measures.

Send your message to us

Waterproof PE Tarpaulin 70-200G Blue Color

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords