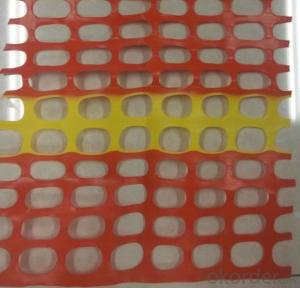

Warning Fence Net for American Market

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Choose CNBM

(1) Technical team: We have a professional technical team. Customer's sample is always welcomed.

(2) Professional factory: We are manufacturer, specializing in manufacturing plastic textile for 7 years; competitive price with good quality. With UV produced by Germany BASF Chemical Company, the products can be endured at least 3 years.

(3) Sample: We can give out sample in 5 days, but the shipment charge usually paid by your side, the fee of it will be rebound when we have formal order.

(4) Rapid response to your needs: We will answer within 24 hours. Welcome to contact us if you have any problems. We are looking forward to cooperating with you.

Specifications

1.Material:100% new HDPE,UV

2.Size: 1.75x15.30m

3.Useful life:3~5 year

4.Color: Dark,Dark Green,Blue,Orange etc.

5.MOQ: 1X20fcl

6.Delivery time:30 days

| |

|

| | |

Material | 100% new HDPE with UV,long service life |

| | |

Weight/sqm | 120~220gsm |

Size | Width:0.5m-3m, Length: as your request |

Samples | 1). sample time: Within 7-15 days. |

2). Sample charge: According to product details. | |

3). Sample refund: Negotiable | |

4). Send sample: Via TNT, UPS, FedEx, DHL Express | |

Sample is free for you to test the quality | |

Payment | T/T, L/C |

| |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

- Q: How are plastic grain storage bins beneficial for long-term storage?

- Plastic grain storage bins offer several benefits for long-term storage. Firstly, they are highly durable and resistant to rot, pests, and weather conditions, ensuring that the stored grains remain protected and intact. Additionally, plastic bins are easy to clean and maintain, reducing the risk of contamination and spoilage. They also provide airtight and watertight seals, preventing moisture and pests from entering, which further helps in preserving the quality of the grains. Lastly, plastic bins are lightweight and stackable, optimizing storage space and facilitating easy transportation when necessary. Overall, plastic grain storage bins offer convenience, protection, and longevity, making them highly beneficial for long-term storage.

- Q: Can nursery trays be used for starting annuals?

- Yes, nursery trays can be used for starting annuals. Nursery trays provide a convenient and organized way to start seeds and germinate annuals. They offer proper drainage and airflow, allowing the seeds to grow healthy and strong before being transplanted into the garden or larger pots.

- Q: okaii so im doing a science project and i found out thath you donate plastic bags to supermarkets but what do they do with the plastic bags do they reuse them and give them to other customers or do they make new bags out of them

- Q: Can I recycle plastic bags? A: Yes, plastic grocery or merchandise bags, dry cleaning bags, and bubble wrap can now be recycled. To be sure this is a successful program, please place only the types of bags requested and remove all receipts, other packaging material, and any food residue. It does not matter if the recycling symbol is not on the bag or if a certain number is inside the chasing arrows on the bag. They can all be placed in the plastic bag bin. Plastic bags cannot be recycled with rigid containers because they have a different melting point. The plastic bags melt very quickly compared to rigid containers and therefore cannot be used in the same process. The plastic bags will be mixed with urban wood waste then melted into a new siding product in residential and commercial construction that is resistant to rot. Plastic bags can also be used to make plastic lumber for decking, outdoor furniture, and lawn edging. It takes a lot of plastic bags to make a bale, so please bring us your plastic bags and bubble wrap! Plastic bags can be reused and most grocery stores have recycling bins near the front door for plastic bags as well. Instead of using a plastic bag, try using durable canvas bags on your next shopping trip!

- Q: Can ground cover plants be used to create a low-cost garden solution?

- Yes, ground cover plants can be an excellent low-cost garden solution. They are typically affordable to purchase and require minimal maintenance, reducing the need for costly fertilizers, pesticides, and watering. Additionally, ground cover plants help suppress weeds, prevent soil erosion, and provide insulation to the soil, saving money on weed control and soil amendments. Overall, they offer an economical and sustainable option for creating a beautiful garden.

- Q: what if a person used an undertank heater for a plastic box like rubbermaid or sterilite that is home to a snake. would the plastic box release poisonous fumes or would the heater not affect the plastic? also, what are some recommendations for not putting the heater directly onto the box. i've heard that some people put the heater on a ceramic tile, and put the tile under the plastic box. thanks

- Yes you can. But I recommend taking a length of heat tape or heat cable attached to a thermostat. That's what people use in their racks, and it is just as effective, and doesn't stick.

- Q: How does ground cover affect water conservation?

- Ground cover significantly affects water conservation by reducing evaporation, preventing erosion, improving soil moisture retention, and promoting infiltration. A dense ground cover, such as grass or mulch, acts as a natural barrier that reduces water loss due to evaporation from the soil surface. It also prevents soil erosion by slowing down the flow of water, allowing it to infiltrate into the ground rather than being washed away. Additionally, ground cover helps to retain moisture in the soil, reducing the need for irrigation and promoting healthy plant growth. Therefore, the presence of adequate ground cover plays a vital role in conserving water resources.

- Q: i put some gaslione in a plastic cup, then left to get a better container for it, when i returned the plastic cup's bottom fell out and spill gas everwherei didn't know gas can do this...what makes gas eat plastic? how?how come it dosent' eat plastic gas can's (gas containers)

- by the same means that petrol because of its additives will burn your skin but will not make any head way on a rubber Tyre,look at the mark it makes around your filler cap on the back wing and you will come to the conclusion that petrol manufactures add a small amount of acid in the petrol to keep the rust at bay, petrol after all is 80% water.

- Q: my cat always licks plastic bags/plastic folders and sometimes tries to chew them. its funny but im kind of worried whta will happen if she ever digests any plastic

- no longer basically does he lick them, yet he likes to chew on them too. The journey isn't that grand whilst it rather is 3:00 in the morning . the terrific ingredient to do is to confirm you hid the plastic. inform you cat to easily say no! Plus there's a danger that the plastic would properly be ingested and could harm the cat in some way.

- Q: Can ground cover be used to create a natural sound absorber?

- Yes, ground cover can be used to create a natural sound absorber. Ground covers such as grass, shrubs, and low-growing plants can help absorb sound waves and reduce noise levels in an environment. The dense vegetation and foliage of ground cover plants can act as barriers to sound, absorbing and scattering the sound waves, thereby reducing echo and noise pollution.

- Q: I'm currently searching for new glasses, and to save money I was thinking of getting plastic lenses instead of polycarbonate. I know polycarbonate is shatter proof, but I already have a pair of beat up polycarbonate eye glasses that I use for sports/play. The plastic lense glasses would strictly be used just for casual things.Also, I have somewhat of a high prescription (-3.00, and -3.50), do you think the lenses would be very thick? I'm thinking of getting thick preppy designer frames, so I doubt it's very noticeable... Is there anything else I need to know about plastic lenses? Any tips? Further warnings I should know about? Give me your recommendation please!

- If you can get a scratch-resistant coating then that would be better. Also, they can cut off the edge so it doesn't look as thick. I think they call it rolling the edge. Of course both cost more. I have high-index plastic in a metal frame that isn't very wide and they look okay. I am about three times as blind as you are too. Plain plastic will be much thicker. You ought to go to a eyeglass place and ask them to show you how thick plastic lenses in your prescription will be. You don't have to buy any that day or even at that place. But then you can see about what you will be getting, and it won't cost you anything to see.

Send your message to us

Warning Fence Net for American Market

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords