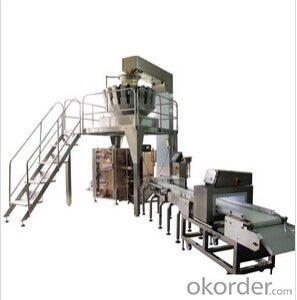

VP42II Automatic Food Packaging Machines

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Advantage

* #304 stainless steel using

* Packing fast and stable

* Mastered the core technology of packaging machines

Product List

NO. | Model | Products name | Quantity |

1 | VP42II | Basic machine | 1 set |

2 | MD14 | 14 heads combination weigher | 1 set |

3 | TK9 | Z type bucket elevator(vibration) | 1 set |

4 | P1.7-1.8) | Supporting platform | 1 set |

5 | TP200 | Finished product conveyor | 1 set |

6 | Stochastic forming | 1 set | |

7 | Wooden case packing charge | 1 set |

VP42II automatic food packaging machine

Superiority

*Low investment, high return, high speed, high efficiency

*Imported PLC computer control system, man-machine interface, large display and easy touch-screen operation.

*Servo film transporting system, horizontal sealing servo control, accurate positioning, machine performance

*Maximize the reliability and intelligence of the whole machine.

Item | Content |

Capacity | 70-100 bag/min,it is according to quality of wrapping and supplies |

Accuracy | ≤±1.5% |

Bag size | (L)60-300mm (W)90-200 mm |

Film width | 420mm |

Bag type | Pack with film, upper seal, lower seal and back seal by automatic bag making machine. |

Filling range | 150-1300ml |

Film thickness | 0.04-0.09mm |

Package material | Thermal composite material., likeBOPP/CPP, PET/AL/PE etc |

Air consumption | 0.8Mpa 0.5m3/min |

Total powder | 5.75KW |

Voltage | Four wire three phase 380V 50HZ |

Air compressor | Not less than 1 CBM |

Total height | 3.760m |

Application

Suitable to package fragile materials demanding high accuracy,such as

puffedfood,crispy rice,jelly,candy,pistachio,apple slices,dumpling,chocolate,pet

food,small hardware,medicine,etc.

The 14 heads weigher

Features

Main feature

Load cell infeed detection, more compatible for harsh working environment (dusty).

Automatic frequency control function to improve the passing rate.

Independently adjustable amplitude,more user friendly.

Staggered dumping mechanism to prevent material blockage.

Multi-language operating interface.

Mouse, USB and SD card compatible 10” touch screen

High grade (IP65) waterproof and dustproof design, more durable in wet and dusty working environment.

Instant display of the weight inside each hopper.

Application Range:

Cereal, pasta, pet food, frozen food (frozen dumping), all type of granular products (peanuts, pistachio), confectionary, fresh products (lettuce leaf), bakery food (biscuits). Non-food applications (screws, bolts).

Weigh range | 10-1500g |

Accuracy | 0.5-1.5g |

Max speed | 130wpm |

Weigh volume | 4.0L |

Hopper No. | 14 |

Control panel | 10inch touch screen |

Driving Device | Stepper motor |

Power supply | AC 110/220±5V, 50/60 Hz |

Power | 1 .3KW |

Size | 1246×1238×1388(mm) |

Weight | 400kg |

P1.7-1.8 Supporting platform P1.7-1.8

Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

Specification

The size of the supporting platform is according to the type of the machines.

TP200

Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

Lifting height | 0.6m-0.8m |

Lifting capacity | 1 cmb/hour |

Feeding speed | 30m\minute |

Dimension | 2110×340×500mm |

Voltage | 220V/45W |

- Q: What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping machinery should have rolling, holding, brushing, packaging machinery, bagging, weighing, sealing.

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: What machine does the packing carton machine have?

- Do the carton machinery: corrugated production line / single machine, printing machine, polishing machine, laminating machine, mounting machine, die-cutting machine, book paste machine for package machinery: automatic sealing machine, automatic strapping machine

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

Send your message to us

VP42II Automatic Food Packaging Machines

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords